Non-contact optical precision measurement method for small modulus arc gears

An arc gear, optical precision technology, applied in the field of precision measurement, can solve the problems of geometric parameter pitch deviation, difficult measurement, maximum tooth thickness deviation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

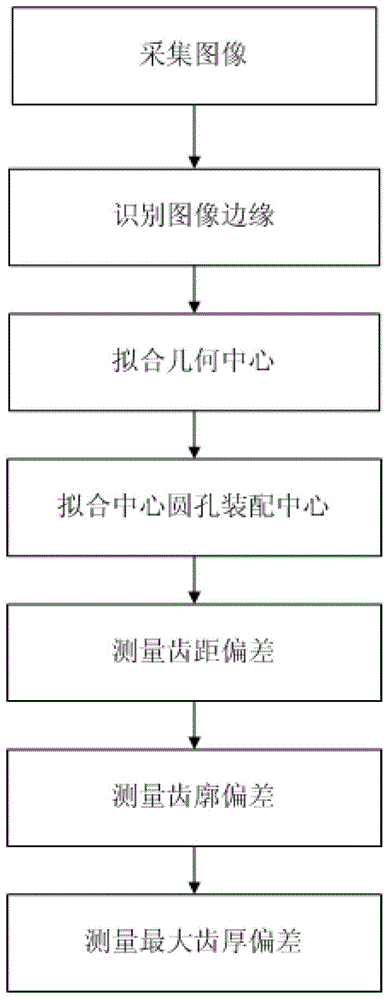

[0065] See attached figure 1 , a non-contact optical precision measurement method for small modulus arc gears, the steps are as follows:

[0066] Step 1, collecting microscopic images of small modulus arc gears;

[0067] Use the machine vision detection system to collect the microscopic image of the small modulus arc gear. The machine vision detection system includes a mobile platform in the three directions of X, Y and Z, which can realize the precise positioning of the detection object; when collecting, the small module The digital arc gear is placed on the inspection platform, and by adjusting the moving platform in the three directions of X, Y, and Z, the small modulus arc gear can be clearly imaged within the field of view of the camera, the image is collected, and the captured picture is saved;

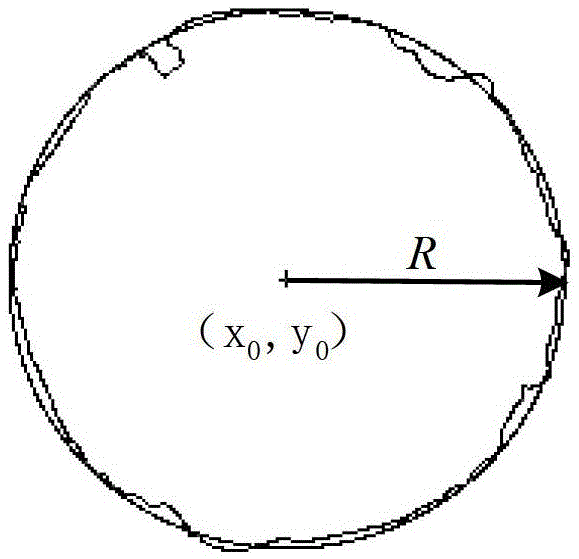

[0068] See attached figure 2 , step two, using the BP neural network algorithm to automatically and accurately identify the edge of the small modulus arc gear image;

[0069...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com