Sand-carrying performance test device for fracturing liquid by adopting high-speed photography and digital image technologies

A digital image and high-speed photography technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems that the distribution of suspended sand cannot be tested, and the sedimentation velocity of sand-carrying fracturing fluid cannot be accurately reflected, and the effect of bright light without flickering can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

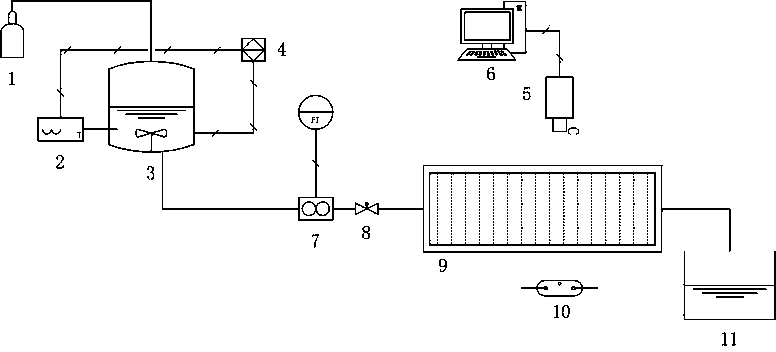

[0016] Further illustrate the present invention below in conjunction with accompanying drawing.

[0017] see figure 1 .

[0018] The fracturing fluid sand-carrying performance test device using high-speed photography and digital image technology mainly consists of air compressor air storage tank 1, temperature sensor 2, liquid storage tank 3, temperature controller 4, high-speed camera system 5, and digital image processing system 6. It is composed of visual simulation crack suspension system 9 and liquid collection tank 11. The liquid storage tank 3 is equipped with sand-carrying fracturing fluid, and its two ends are connected with a temperature sensor 2 and a temperature controller 4. The upper part of the liquid storage tank is connected to the air compressor gas storage tank 1, and the lower part is connected to a visual analog crack through a pipeline. Sand suspension system 9 and liquid receiving tank 11, flowmeter 7 and needle valve 8 are arranged on the pipeline bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com