Cable clamping device and cable segmenting apparatus using cable clamping device

A cable and cable clamping technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of affecting operation efficiency, cable failure, easy wear, etc., to avoid cable backwards and realize automatic clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

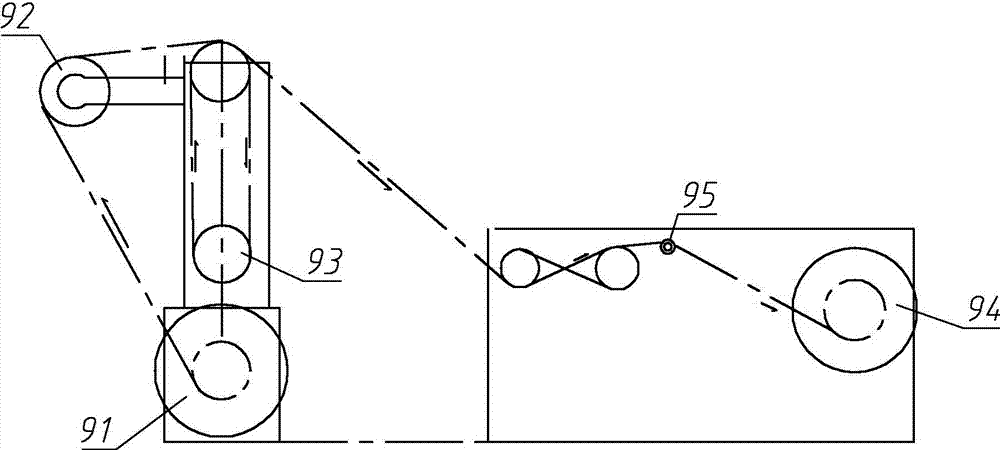

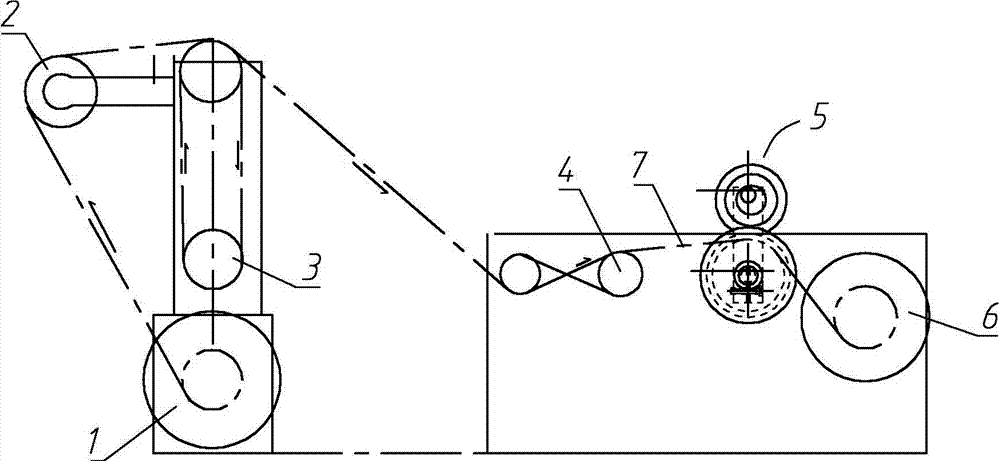

[0023] An example of the cable splitting device in the present invention is image 3 — Figure 5 As shown, it is used for retracting and unwinding of the covered cable, including a cable reel 1, a guide wheel 2, a tension wheel 3, a meter wheel 4 and a cable take-up reel 6, wherein the meter wheel 4 is a prior art, and can calculate the passing The length of sheath optical cable 7 is to facilitate cutting, and the structure of putting cable reel 1, guide wheel 2, tension wheel 3 and cable reel 6 is the same as the prior art, and will not be described in detail here.

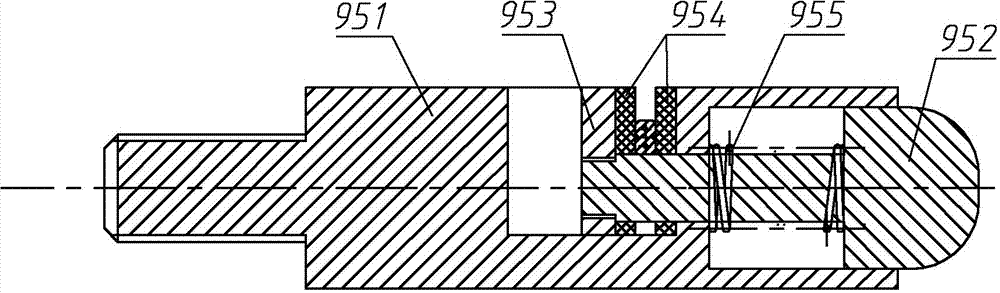

[0024] Between the meter wheel 4 and the cable reel 6, there is a clamping device 5 for clamping and fixing the leather cable 7. The clamping device 5 includes a support seat 51 as the main body of the device, and the support seat 51 is provided with a There are support guide wheel shafts 52 and ratchet shafts 54 whose axes are parallel to each other. The support guide wheel shafts 52 are equipped with support g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com