Full-automatic U-shaped ultrasonic top stop machine and feeding device thereof

A feeding device and ultrasonic technology, applied in the field of automatic U-shaped ultrasonic top stop machine, can solve the problems of low work efficiency, further improvement of welding effect and precision, complex wire feeding structure of the whole machine, etc., and improve the efficiency of forming and welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

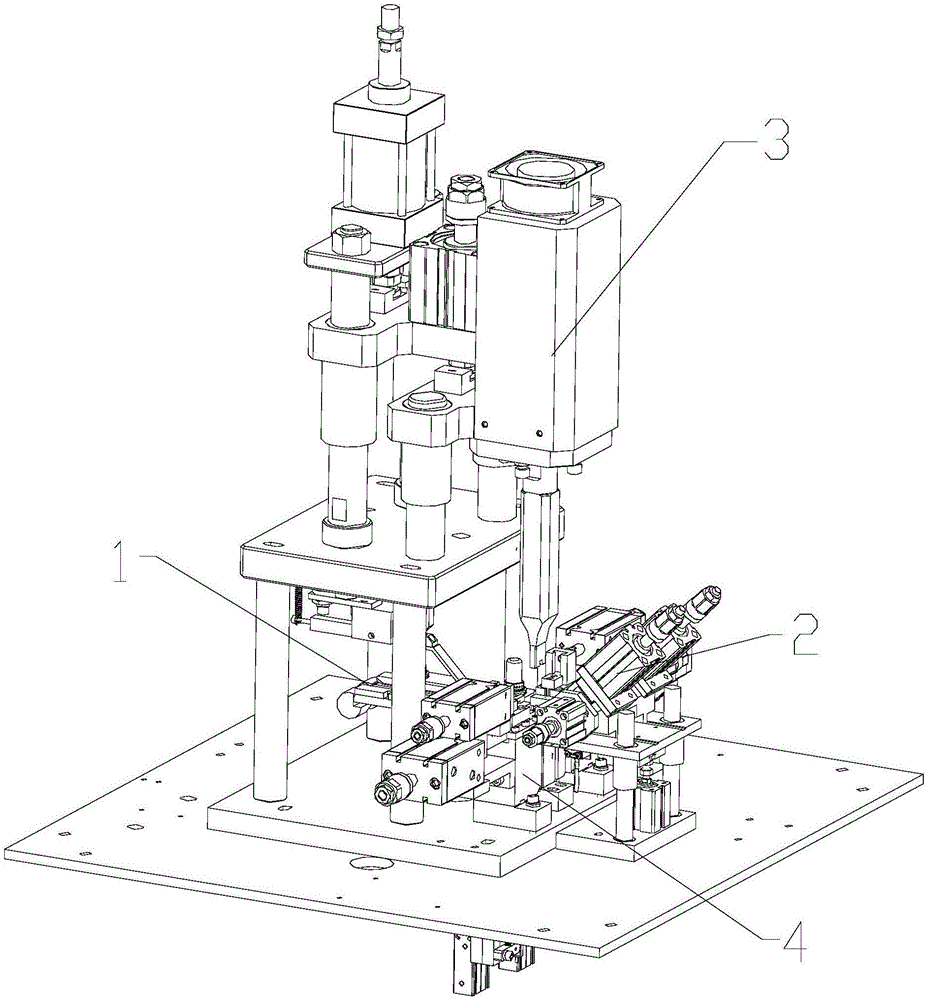

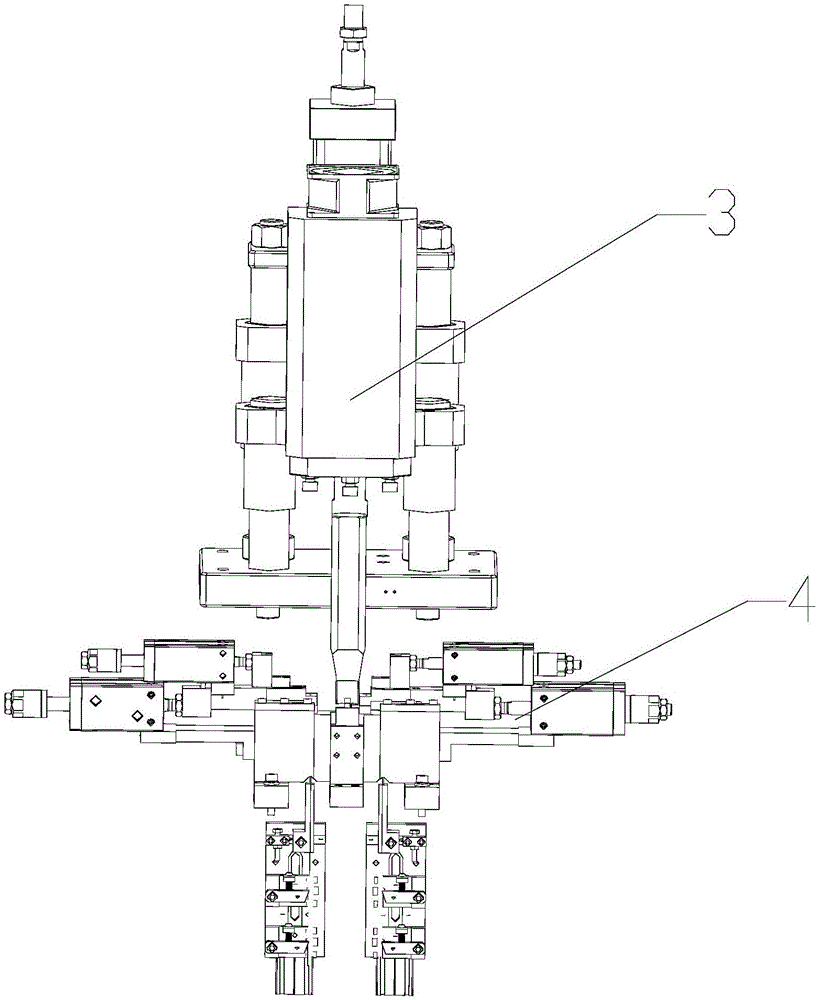

[0033] Such as Figure 1-Figure 12 As shown, the fully automatic U-shaped ultrasonic upper stop machine includes chain passing part 1, chain splitting part 2, sound wave part 3 and wire feeding part 4. The zipper is separated, and at the same time, the plastic flat wire enters from the wire feeding part 4 and is cut off to form a U-shaped top stop, and then the U-shaped top stop is welded to the zipper under the joint action of the sound wave part 3;

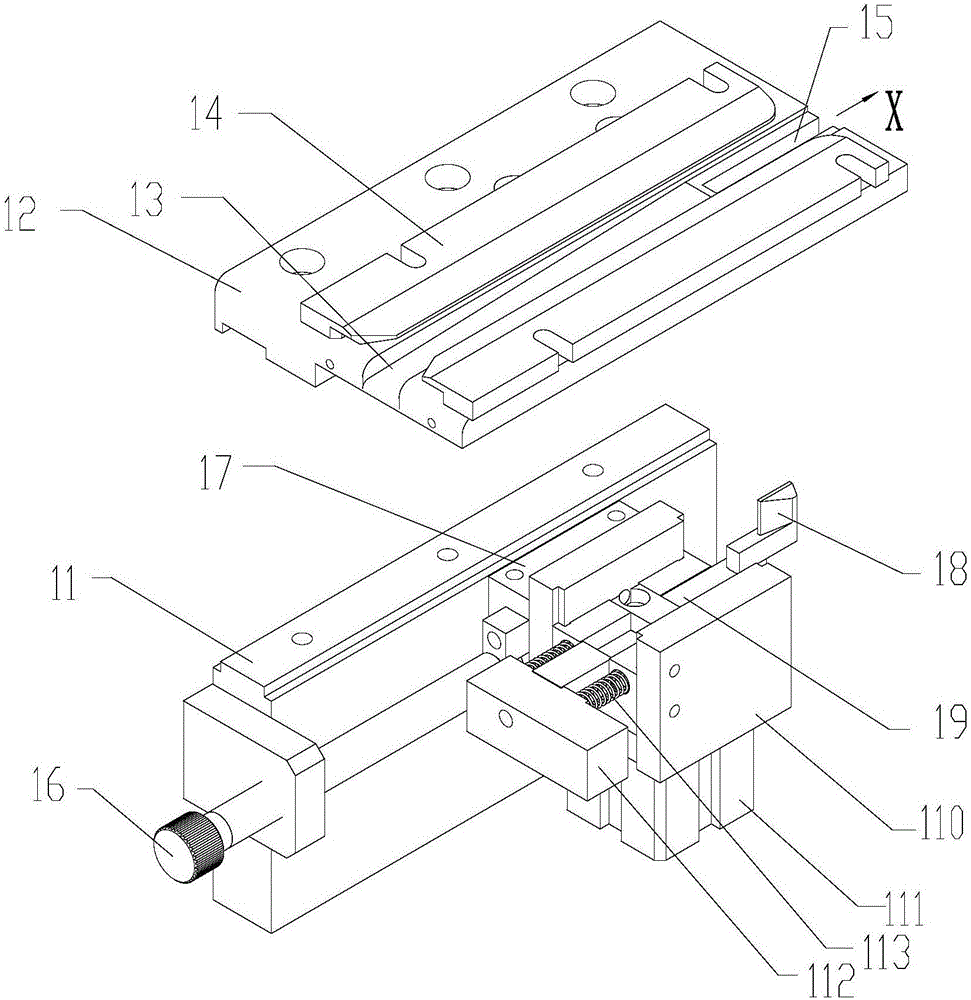

[0034]Wherein, the wire feeding part 4 includes a wire feeding mechanism and a molding die, and the wire feeding mechanism includes a pair of symmetrically arranged wire feeding bases 41, and the edge of one side of the wire feeding base 41 is evenly spaced from bottom to top. The first wire guide seat 42, the second wire guide seat 42 and the third wire guide seat 44 are installed, and the first w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com