High-voltage transformer

A technology of high-voltage transformers and voltage transformers, which is applied in the direction of transformers, inductors, transformer/inductor coils/windings/connections, etc., which can solve problems such as restrictions on the application and promotion of high-voltage transformers, and achieve excellent anti-loosening effects and easy installation , to ensure the effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

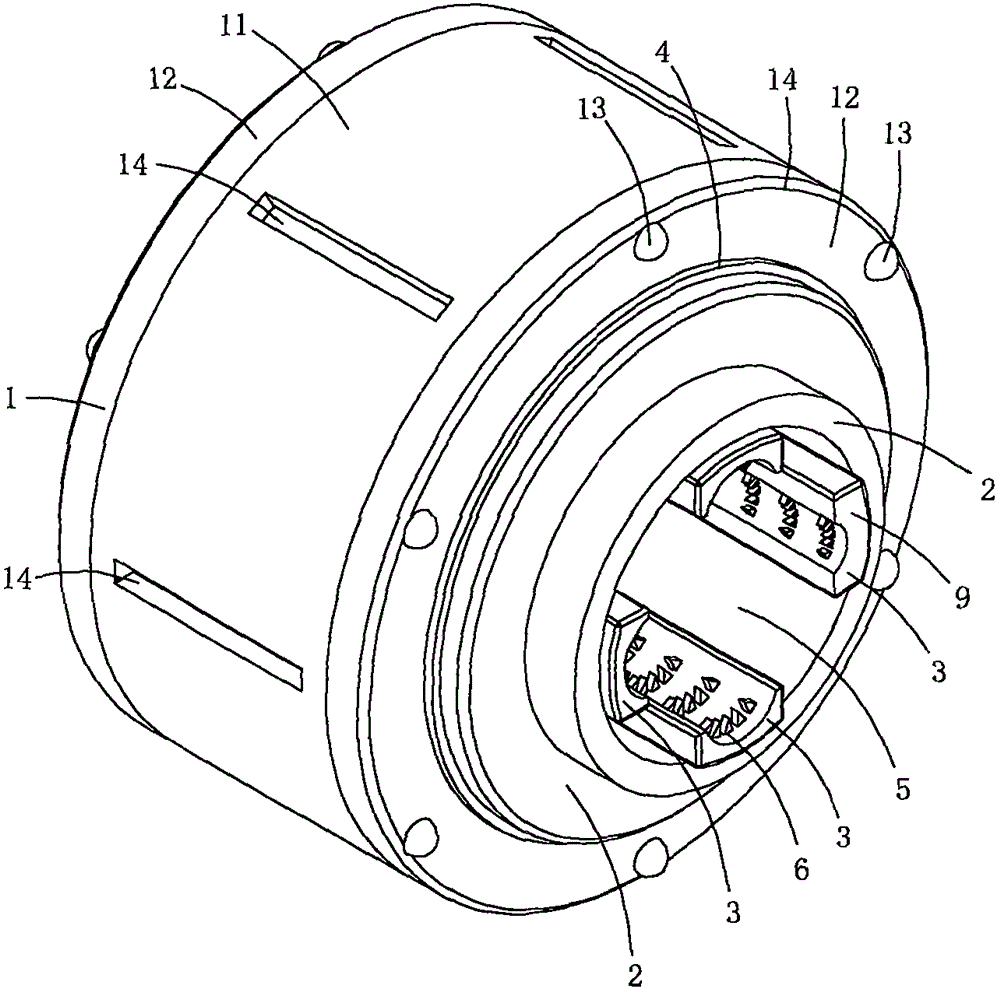

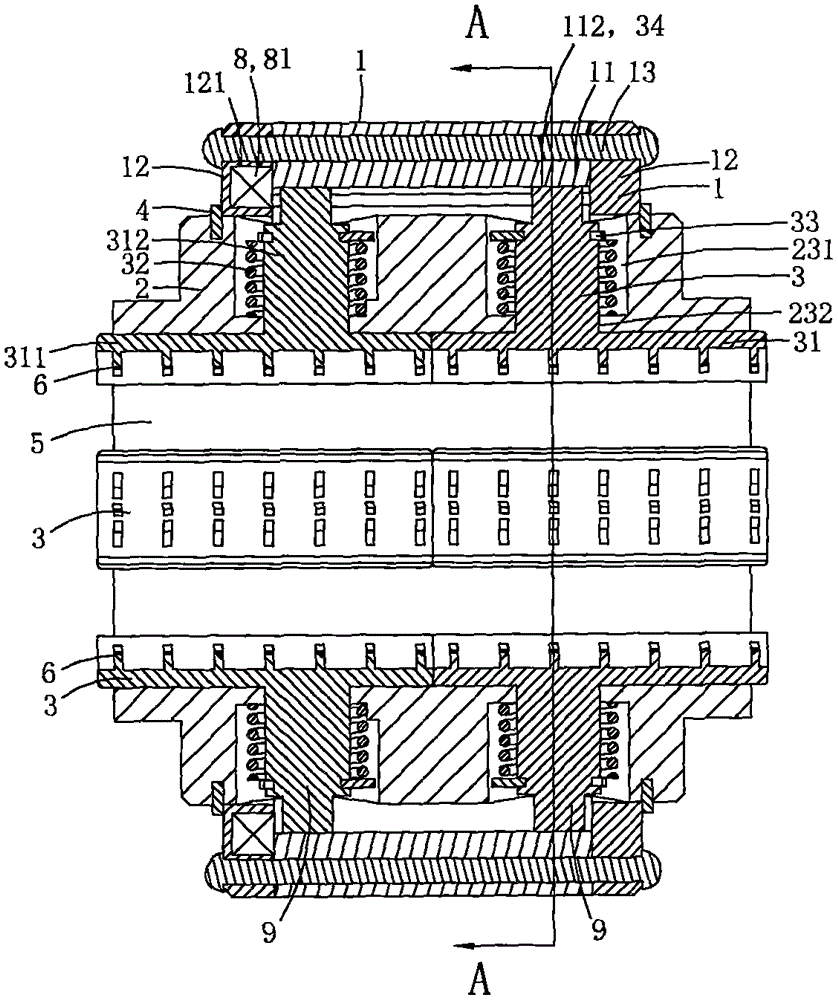

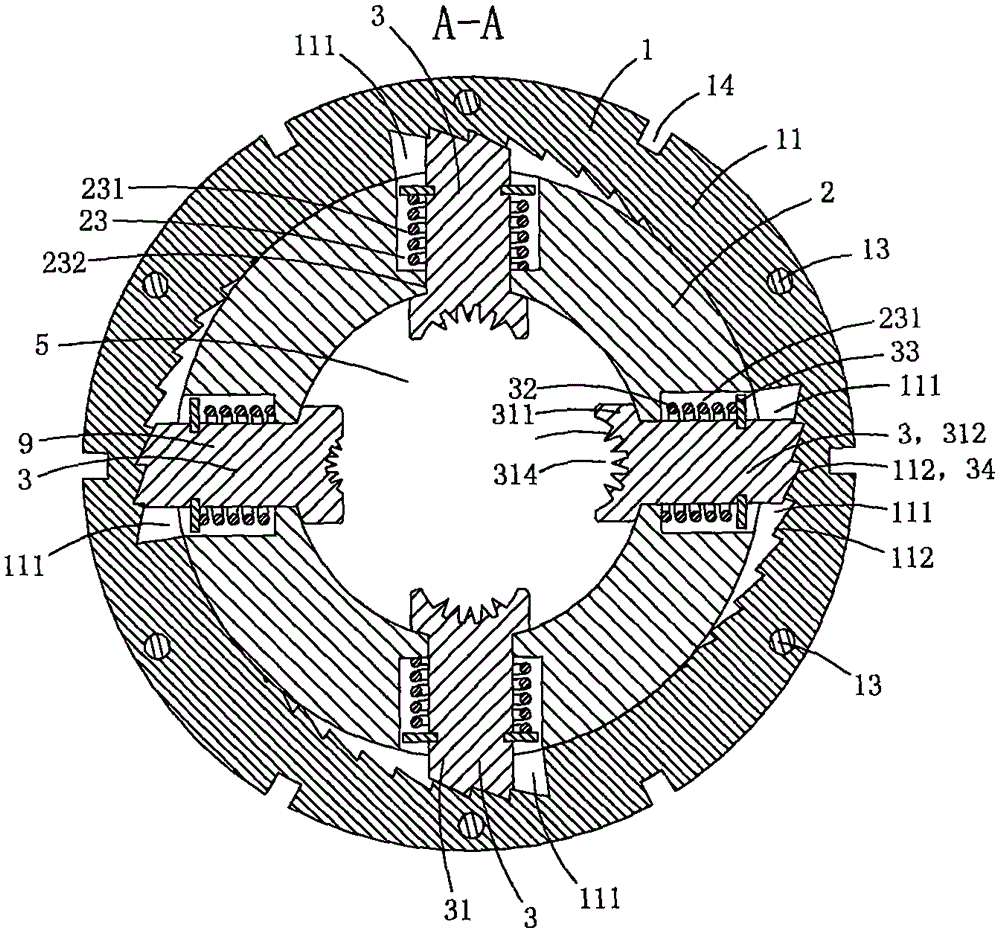

[0019] This embodiment is a high voltage transformer, see Figure 1 to Figure 5 As shown, it includes a compression ring 1 , a core tube 2 , a voltage transformer 8 , two axial retaining rings 4 and two sets of clamping assemblies 9 .

[0020] The pressure ring 1 includes a ratchet ring 11, two clamping rings 12 on both sides of the ratchet ring and a plurality of coupling rivets 13, the two clamping rings clamp the ratchet ring, and the coupling rivets penetrate through the ratchet ring and the ratchet ring along the core tube axial direction. Two clamping rings, so that the ratchet ring and the two clamping rings are fixedly connected as a whole. The inner peripheral wall of the ratchet ring is provided with a plurality of slope grooves 111, and each slope groove is provided with a plurality of wedge-shaped anti-off teeth 112; in this embodiment, the inner peripheral wall of the ratchet ring and the inner peripheral wall of the clamping ring are coplanar, The peripheral wal...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 6 and Figure 7 As shown, the voltage transformer 8 in this embodiment also includes an intelligent control module 82; the outer peripheral wall of the core tube is provided with a placement groove 25, and the intelligent control module is arranged in the placement groove; the intelligent control module may include a wireless transceiver unit and an alarm The buzzer and the intelligent control module transmit the secondary voltage or current signal sensed by the ring base to the remote host through the wireless transceiver unit, so as to realize precise remote unmanned monitoring; this structure can make full use of the space and is conducive to the overall small size and integration.

Embodiment 3

[0035] This embodiment is basically the same as Embodiment 2, the difference is: see Figure 8 As shown, in this embodiment, the annular base body of the voltage transformer is no longer arranged in the clamping ring. In this embodiment, the annular base body of the voltage transformer is fixedly arranged on the outer peripheral wall of the core tube. This scheme is also feasible, and the structure is more Compact and easy to manufacture and process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com