An axial feeding type integrated device for threshing and separating rice and wheat

A threshing separation and feeding technology, which is used in threshing equipment, crop processors, cutters, etc., can solve the problems of long threshing drum length of combine harvesters, high power requirements of combine harvesters, and complex structure of combine harvesters. Achieve the effect of improving separation efficiency and smooth movement performance, low power consumption, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

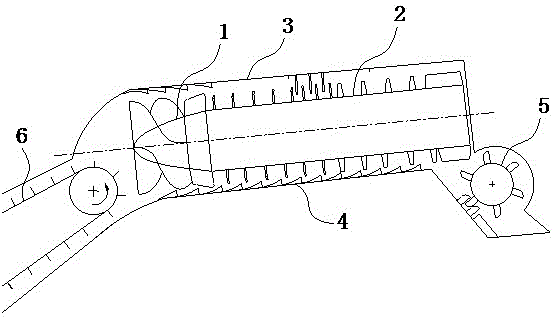

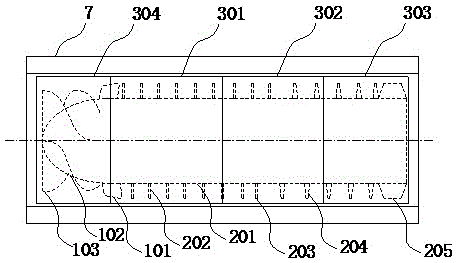

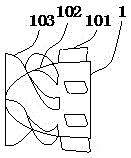

[0062] The invention comprises a material feeding head 1, a longitudinal axial flow threshing and separating drum 2, a threshing grid cover plate 3, and a separating grid concave screen 4, the material feeding head 1 is arranged at the front end of the longitudinal axial flow threshing and separating drum 2, and the threshing grid The grid cover plate 3 is located on the upper side of the longitudinal axial flow threshing separation drum 2, the separation grid concave screen 4 is located on the lower side of the longitudinal axial flow threshing separation drum 2, and the threshing grid cover plate 3 and the separation grid concave screen 4 are enclosed to form A cylinder housing the vertical axial flow threshing separation drum 2;

[0063] The threshing grid cover plate 3 is composed of a feeding head cover plate 304, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com