Modeling pruning machine

A technology for a pruning machine and a locomotive, which is applied to the field of hedge trimmers, can solve the problems of high cost, inability to achieve 360-degree free shape, and complex structure of the modeling pruning machine, and achieves the effects of low cost, simple structure and beautiful shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

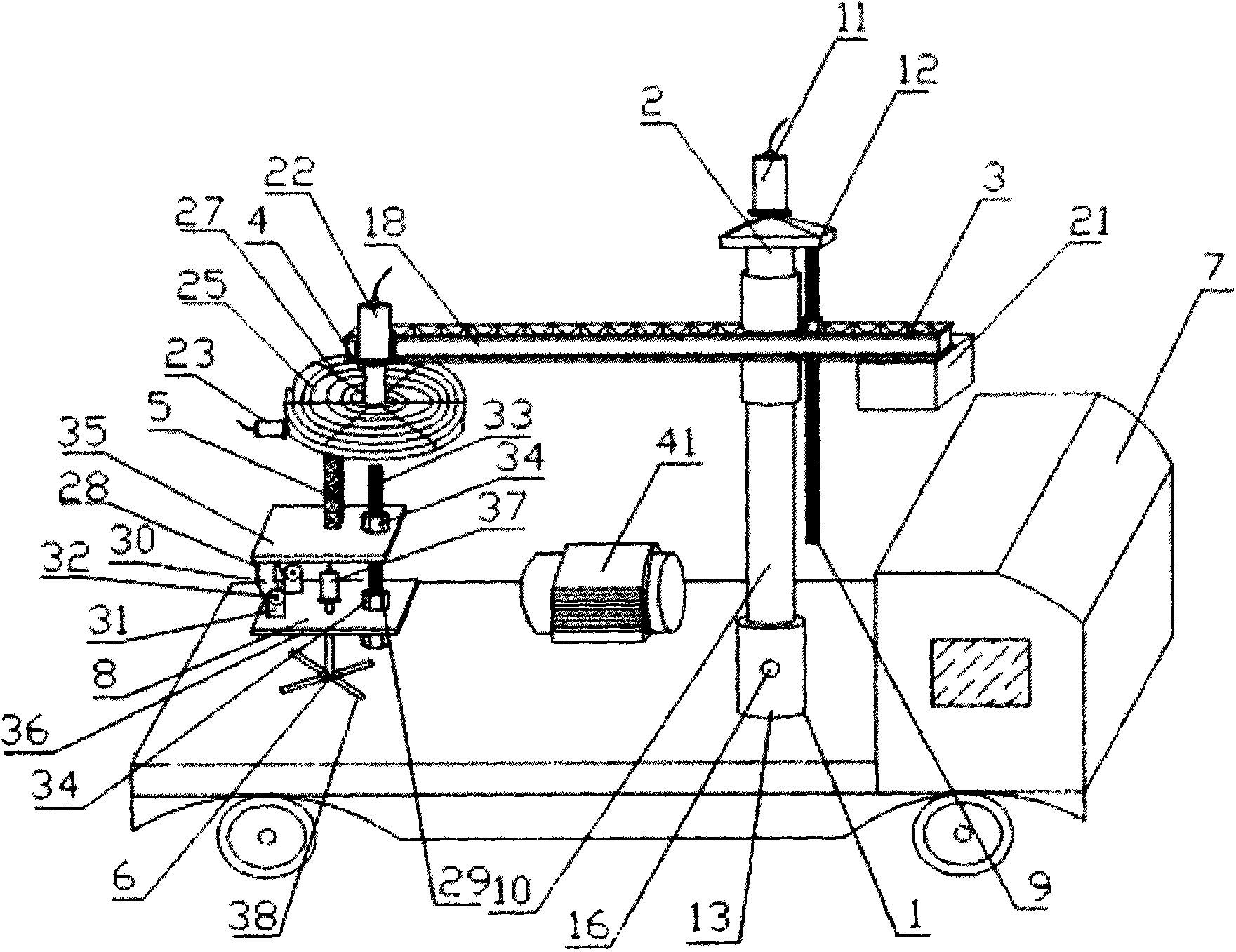

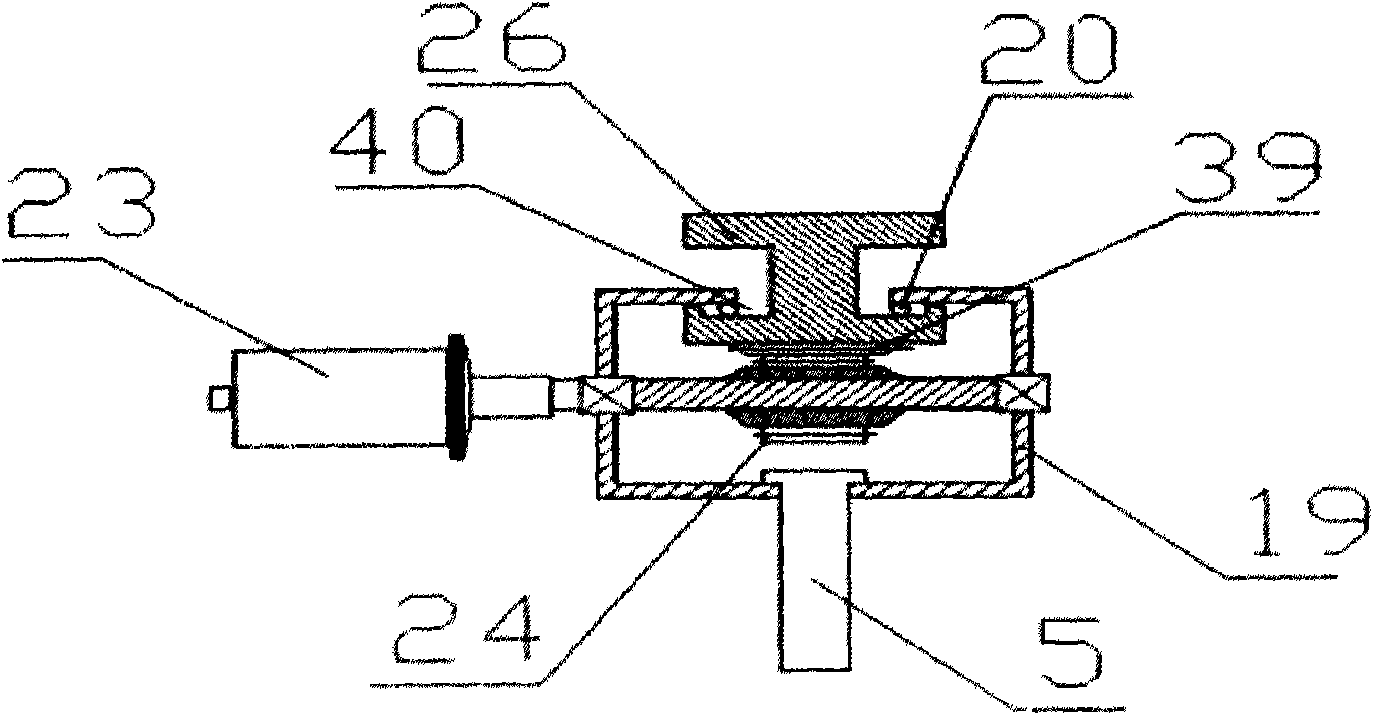

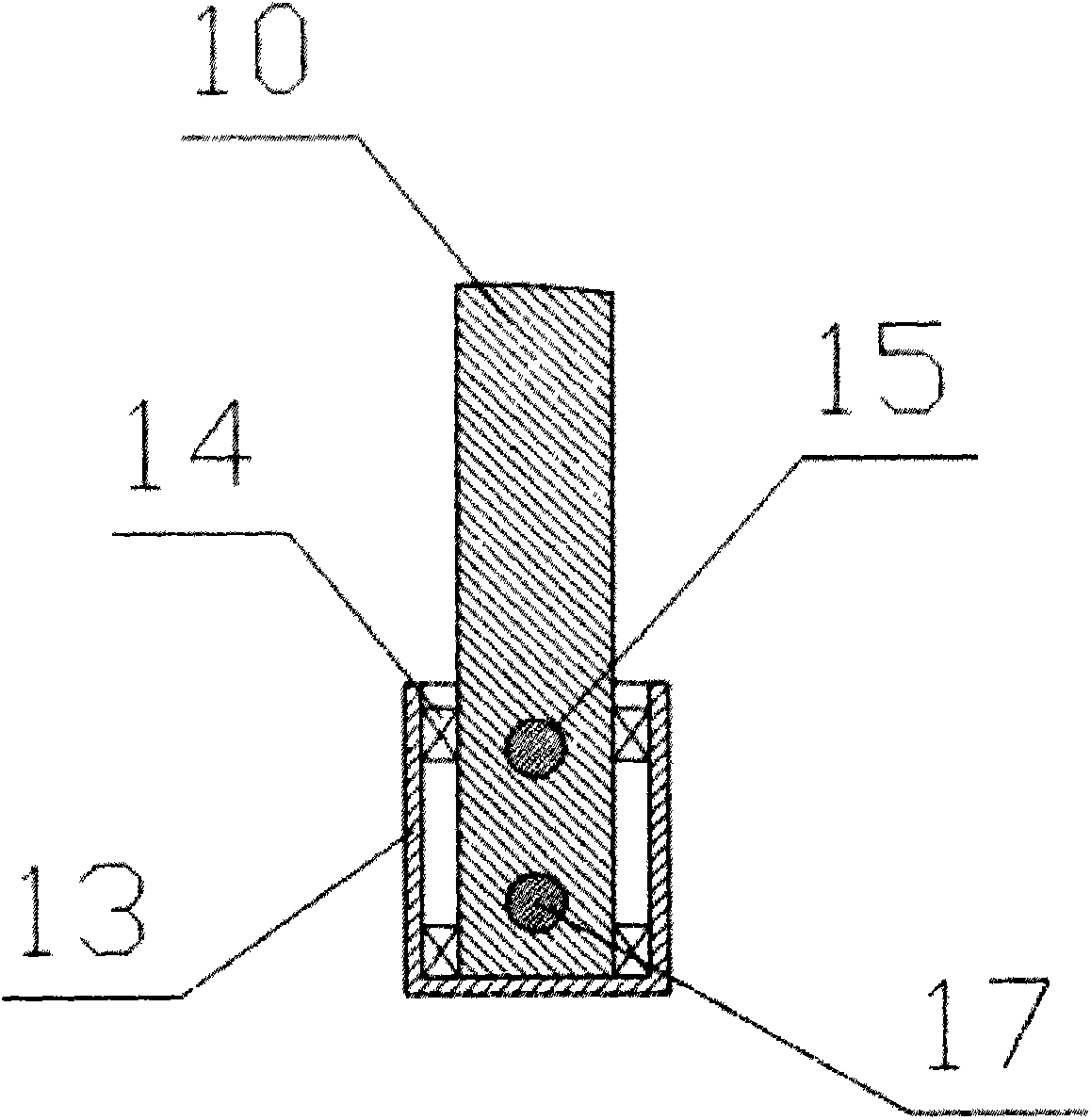

[0028] exist figure 1 In the shown embodiment, a kind of molding pruning machine comprises locomotive 7, and locomotive 7 can be automobile, tricycle, trolley and other movable car bodies, and locomotive 7 is also provided with generator 41, and generator 41 is directed to the shearing machine. The branch machine provides power supply, and the branch trimmer is arranged on the locomotive 7. The trimmer includes a base 1, a lifting support 2, a transverse connecting device 3, a rotating device 4, a longitudinal connecting device 5 and a shearing device 6, and the base 1 and the locomotive 7 Fixed connection, the lifting bracket 2 is connected with the base 1 in rotation, the horizontal connecting device 3 is flexibly connected with the lifting bracket 2, the rotating device 4 is slidably arranged at the end of the horizontal connecting device 3 and can rotate along the horizontal plane, the other side of the horizontal connecting device 3 One end is provided with counterweight ...

Embodiment 2

[0034] exist Figure 4 In the shown embodiment, a kind of modeling pruning machine, its structure is basically the same as that of Embodiment 1, the difference is that: the horizontal connecting device 3 is provided with an adjustment device and a slide rail 18, and the rotating device 4 slides with the slide rail 18 The connection and adjustment device adopt telescopic mechanism 42 and telescopic cylinder 43 to realize the length adjustment of the transverse connection device. The blade 38 is provided with two pieces in an inline structure. Of course, the blade can be arranged in a spiral structure or other structures as required, and a protective cover 44 is also arranged above the blade 38 .

[0035]For the molding pruning machine in the above-mentioned embodiment, the locomotive 7 pulls the molding pruning machine to the place where the operation is required, starts the generator 41 on the locomotive 7, generates power, and provides power supply for the pruning machine. s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com