Electric soldering iron

An electric soldering iron and electric heating technology, applied in the direction of soldering iron, metal processing equipment, manufacturing tools, etc., can solve problems such as danger and false touch, and achieve high safety and significant technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

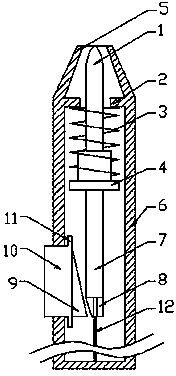

[0013] Do further description below in conjunction with accompanying drawing:

[0014] An electric soldering iron, the electric soldering iron includes an electric heating assembly, a casing 6 and a telescopic mechanism, the telescopic mechanism is fixed in the casing 6, and the electric heating assembly is connected to the telescopic mechanism;

[0015] The telescopic mechanism includes a rebound mechanism and an operating mechanism. The electric heating assembly includes an electric heating head 1, a connecting rod 7 and a power supply line 12. The electric heating head 1 is arranged at one end of the connecting rod 7. The inside of the rod 7 is connected with the electric heating head 1, the connecting rod 7 is fixed with a stroke pressing block 4, the casing 6 is a semi-closed hollow rod, the opening end 5 of the casing 6 is provided with a stroke top block 2, and the stroke A spring 3 is arranged between the pressing block 4 and the stroke top block 2, and the stroke pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com