High-coating-rate reconstituted tobacco coating machine

A technology of high coating rate and reconstituted tobacco, which is applied to paper and other fields, can solve the problems of poor quality of reconstituted tobacco products, large loss of coating liquid, difficult cleaning of mesh belt, etc., and achieve high coating rate, high coating operation, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

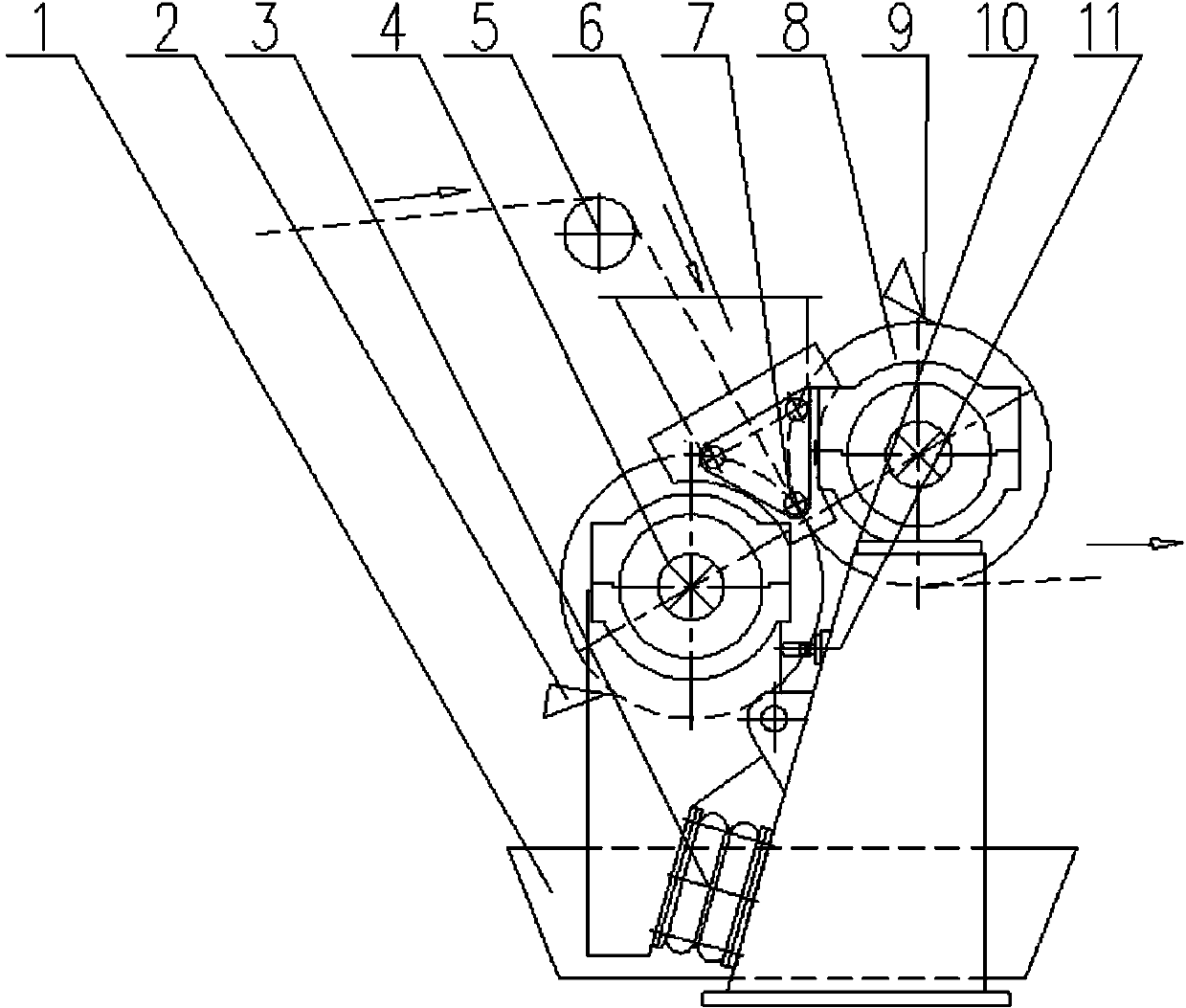

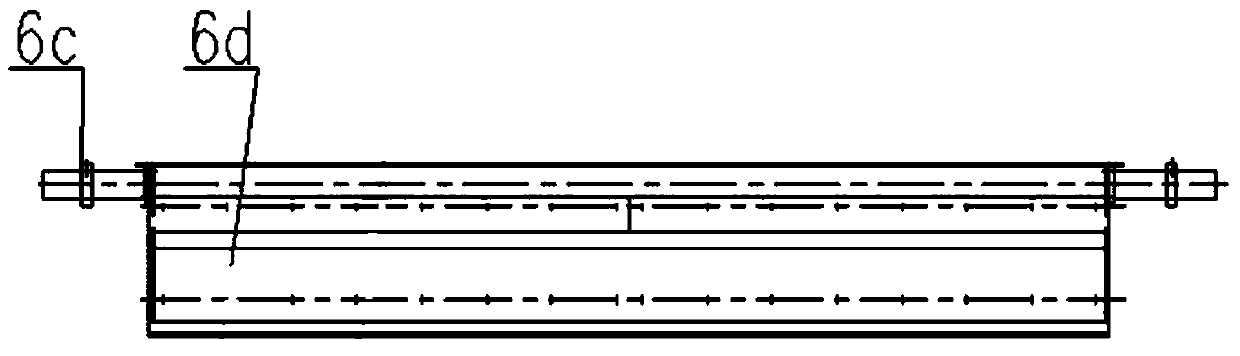

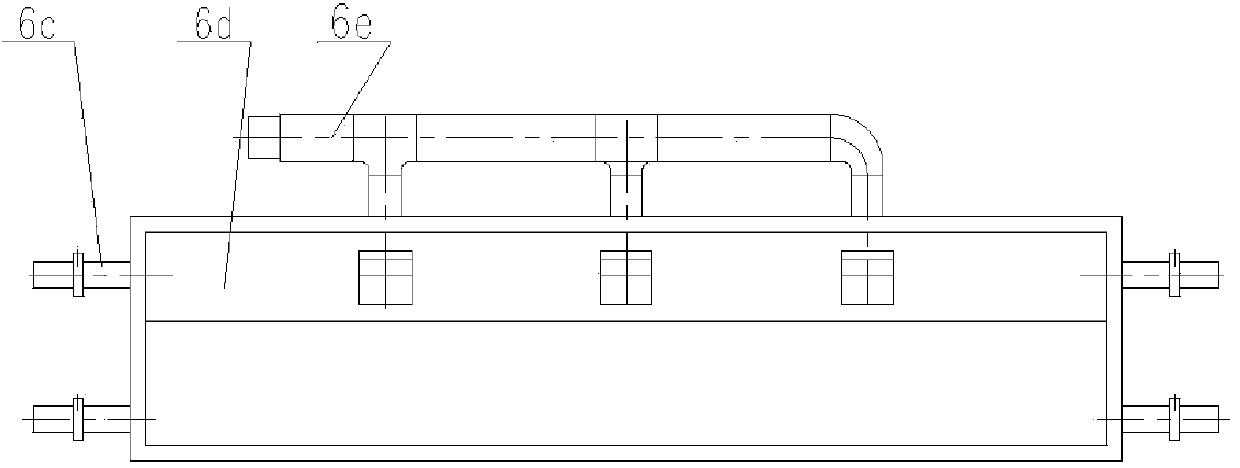

[0016] Such as figure 1 The shown reconstituted tobacco leaf high coating rate coating machine includes at least a receiving tank 1, a moving roller scraper 2, a coating roller pressing device 3, a coating moving roller 4, a paper threading roller 5, and a coating liquid tank 6 , End sealing device 7, coating fixed roller 8, fixed roller scraper 9, frame 10, roller gap adjustment device 11. Coating moving roll 4 and coating fixed roll 8 are installed on the frame 10; coating liquid tank 6 is arranged on the top between coating moving roll and coating fixed roll, and the sealing strip 6b on both sides of the coating liquid tank and The roller surface of the coating moving roller and the coating fixed roller is contact-sealed; the end surface sealing device 7 is symmetrically arranged on the two ends of the coating solution tank, the coating moving roller, and the coating fixed roller to form a sealed coating solution tank; One end of the coating roller pressing device 3 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com