Double-input-shaft speed changer with hydraulic torque converter

A technology of hydraulic torque converter and hydraulic transmission, which is applied in the field of double input shaft transmission and manual transmission, which can solve the problems of difficult starting, tired traffic jams, low maintenance cost, etc., and achieves easy starting, increased climbing ability, and difficult flameout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

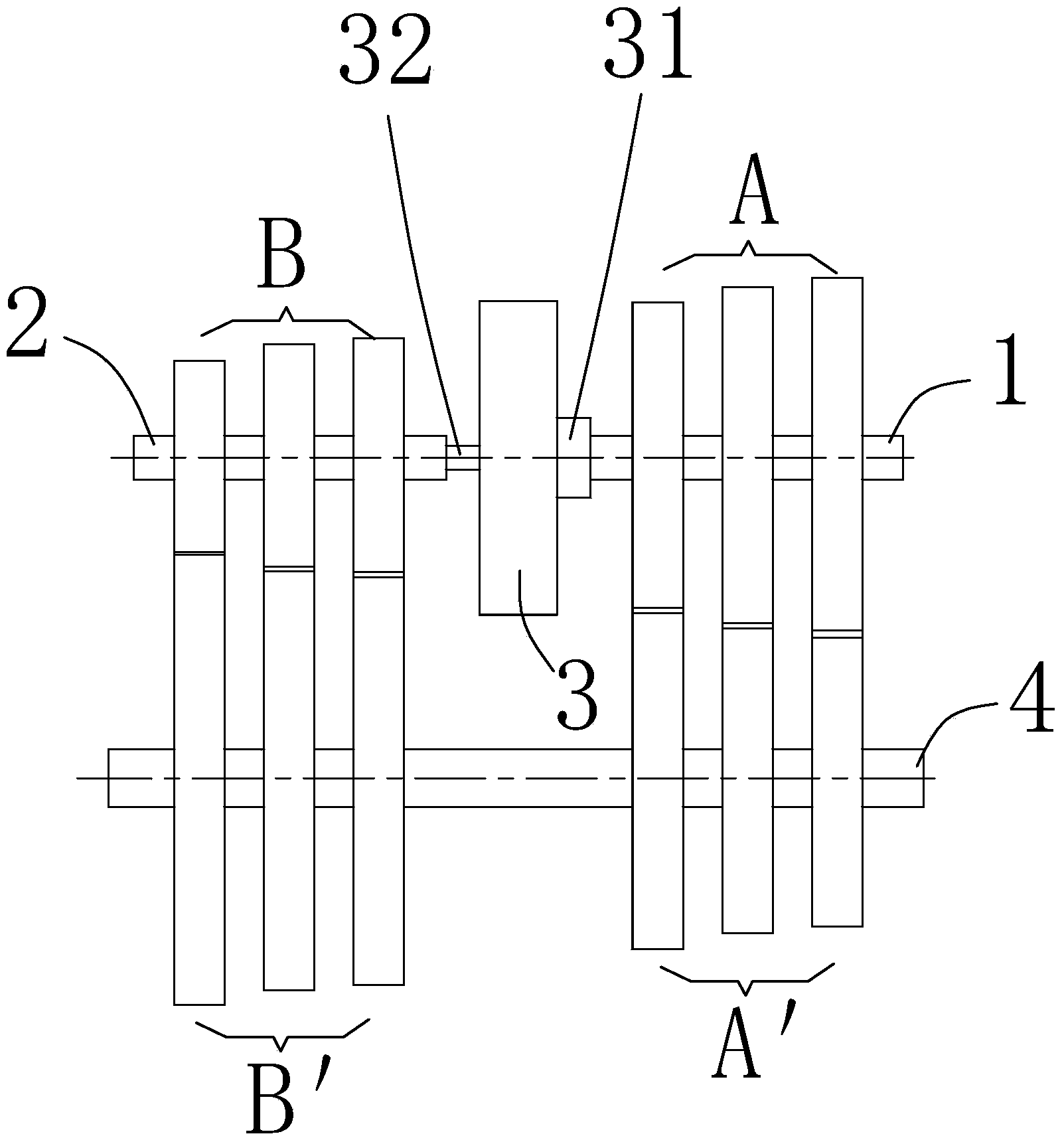

[0020] Such as figure 1 The shown dual-input shaft transmission with hydraulic torque converter consists of main input shaft 1, secondary input shaft 2, hydraulic torque converter 3, transmission output shaft 4, high-gear driving gear set A, low-gear driving Gear set B, high gear driven gear set A' and low gear driving and driven gear set B'. The input shaft 31 and the output shaft 32 of the hydraulic torque converter 3 are respectively located on both sides of the hydraulic transmission 3 , and the axes of the input shaft 31 and the output shaft 32 of the hydraulic torque converter 3 coincide. The main input shaft 1 is connected with the input shaft 31 of the hydraulic torque converter 3, the secondary input shaft 2 is connected with the output shaft 32 of the hydraulic torque converter 3, the main input shaft 1, the secondary input shaft 2 are connected with the hydraulic torque converter 3 coaxial setting. The output shaft 4 of the transmission is parallel to the axis of ...

Embodiment 2

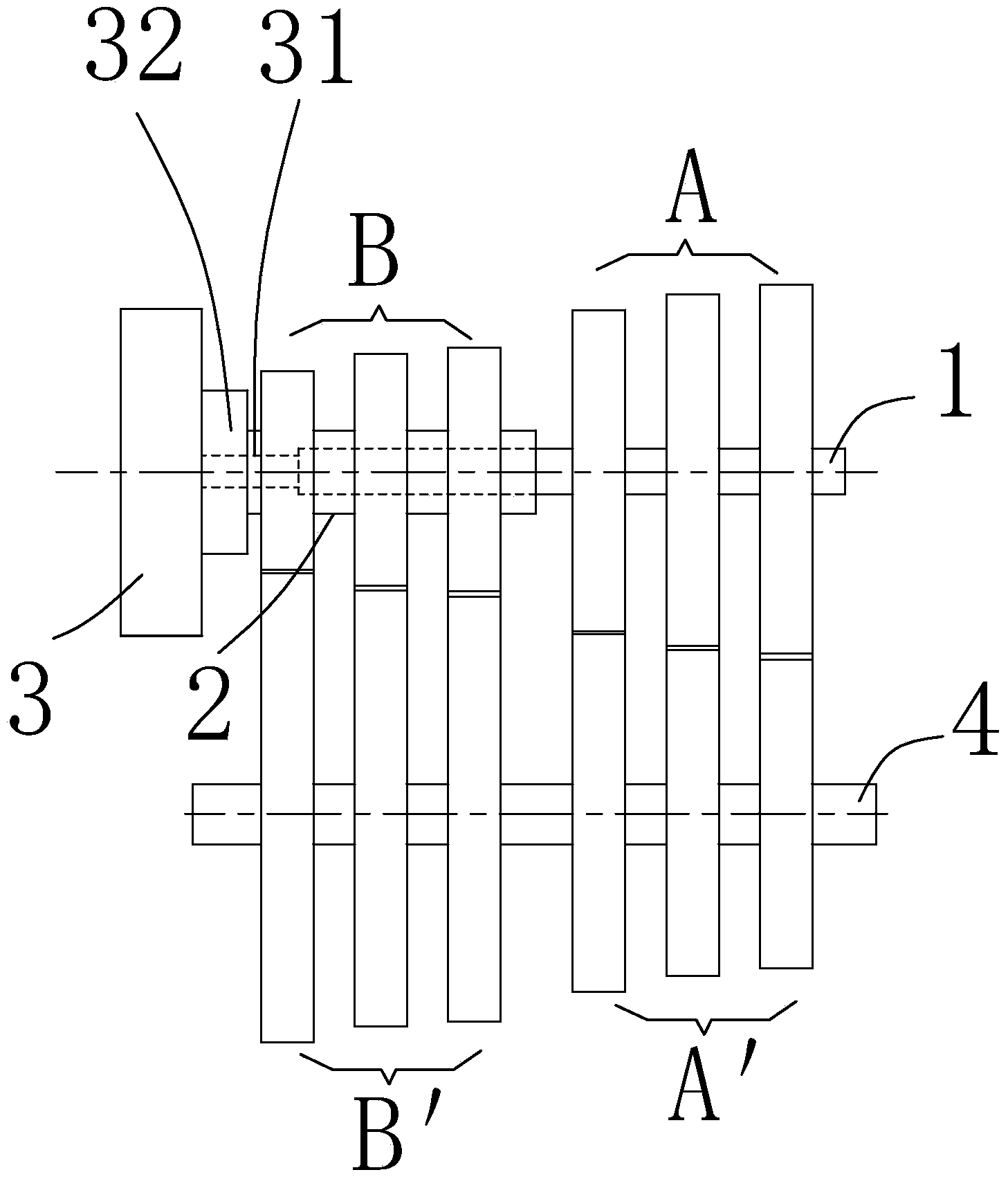

[0023] Such as figure 2 The shown dual-input shaft transmission with hydraulic torque converter consists of main input shaft 1, secondary input shaft 2, hydraulic torque converter 3, transmission output shaft 4, high-gear driving gear set A, low-gear driving Gear set B, high gear driven gear set A' and low gear driven gear set B'. The axes of the input shaft 31 and the output shaft 32 of the torque converter 3 coincide. The main input shaft 1 is connected with the input shaft 31 of the hydraulic torque converter 3, the secondary input shaft 2 is connected with the output shaft 32 of the hydraulic torque converter 3, the main input shaft 1, the secondary input shaft 2 are connected with the hydraulic torque converter 3 axes coincide. The output shaft 4 of the transmission is parallel to the axis of the main input shaft 1. The main input shaft 1 is equipped with a high-speed driving gear set A, such as the third, fourth and fifth gears, and the secondary input shaft 2 is equi...

Embodiment 3

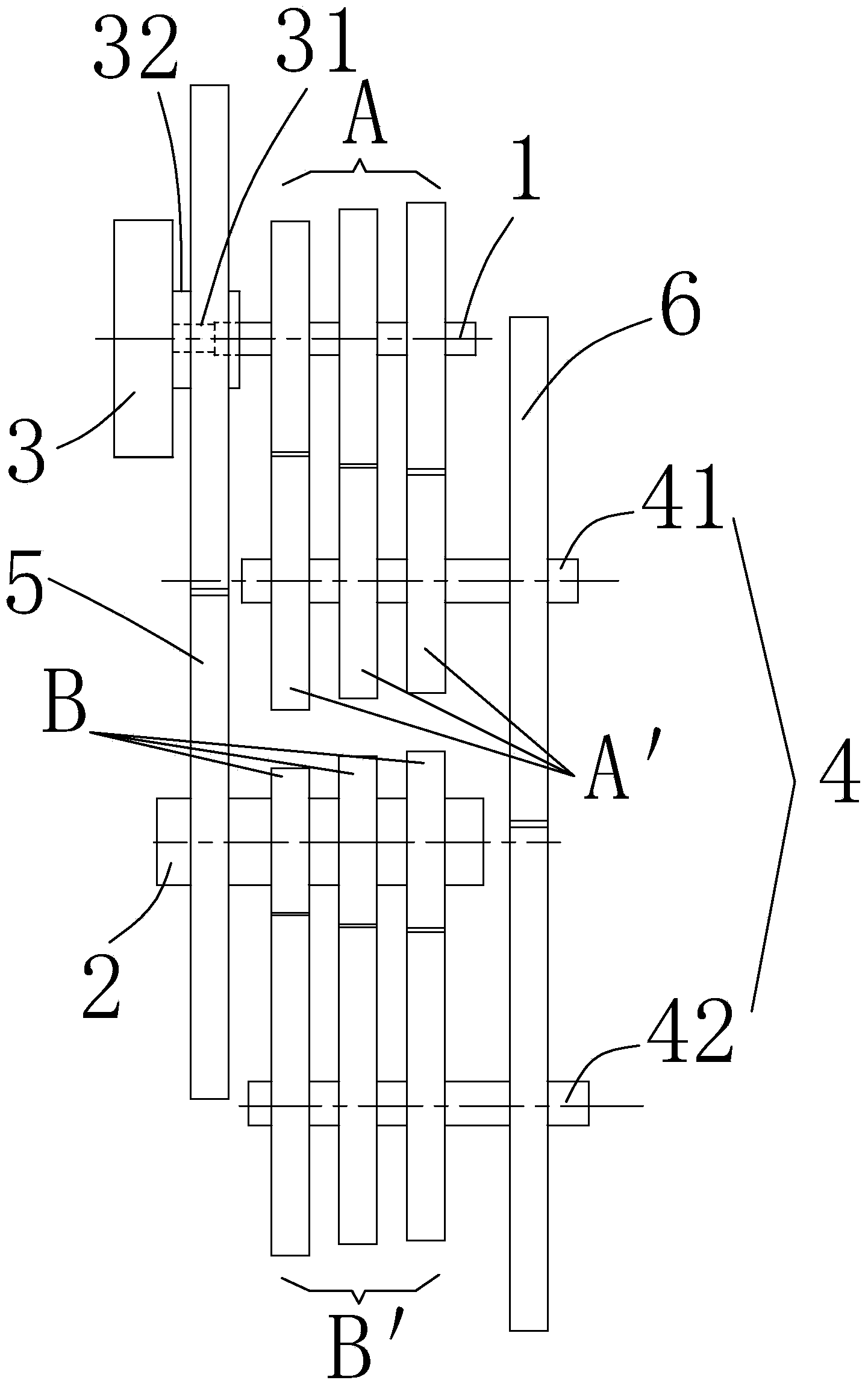

[0027] Such as image 3 The shown dual-input shaft transmission with hydraulic torque converter consists of main input shaft 1, secondary input shaft 2, hydraulic torque converter 3, transmission output shaft 4, high-gear driving gear set A, low-gear driving The gear set B, the high gear driven gear set A', the low gear driven gear set B', the first transmission gear set 5 and the second transmission gear set 6 are composed. The torque converter 3 is arranged coaxially with the main input shaft 1, the input shaft 31 and the output shaft 32 of the torque converter 3 are located on the same side of the hydraulic transmission 3, the input shaft 31 and the output shaft of the torque converter 3 The axes of the shafts 32 coincide, and the output shaft 32 is coaxially sleeved outside the input shaft 31 . The main input shaft 1 and the secondary input shaft 2 are arranged in parallel, the main input shaft 1 is connected with the input shaft 31 of the torque converter 3, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com