Tester for elastohydrodynamic lubricating oil film traction with spinning

A lubricating oil film and traction force technology, applied in the field of testers, can solve the problems of complex adjustment process, instability, leakage, etc., and achieve the effect of obvious force increase effect, convenient adjustment and large loading range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following embodiments.

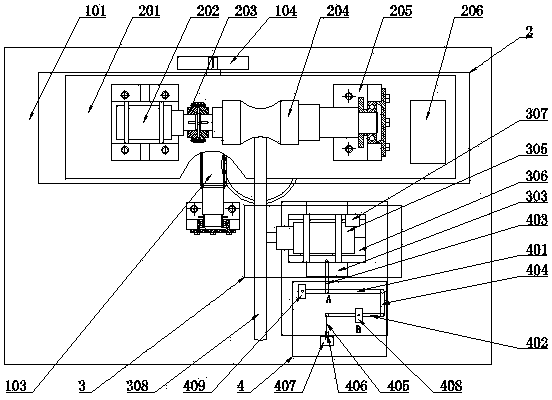

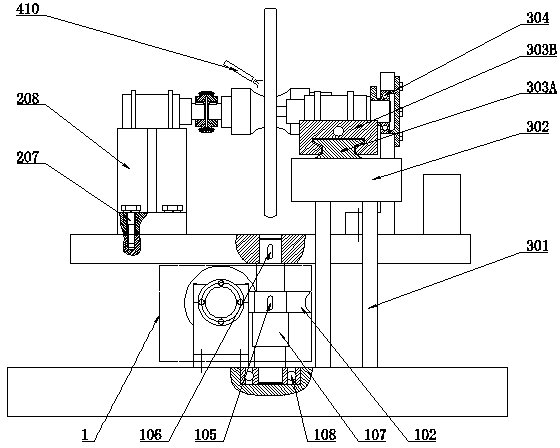

[0030] As shown in the accompanying drawings, an elastohydrodynamic lubricating oil film traction tester with spin is composed of a worm gear mechanism (1), an angle conversion mechanism (2), a linear guide mechanism (3) and a lever-pulley loading mechanism (4 )composition;

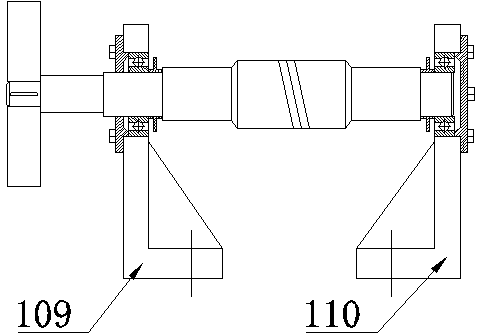

[0031] The elastohydrodynamic lubricating oil film traction tester with spin described above includes: a large base plate (101), a stepped shaft (107), a small base plate (201), and an electric spindle I (305) , electric spindle II (202), coupling (203), groove test piece (204), ball test piece (308), linear guide (303), V-groove (306), worm wheel (102), worm shaft ( 103), lever I (401), lever II (402), fixed pulley (406) and traction sensor (307), the large base plate (101) is connected with the small base pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com