Personalized artificial vertebral implant and its design method based on additive manufacturing

A technology of additive manufacturing and implants, which is applied in the field of medical devices, can solve the problems of increasing surgical blood loss, increasing operation time, and increasing intraoperative infection, so as to benefit spine function, reduce operation risk, and reduce operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

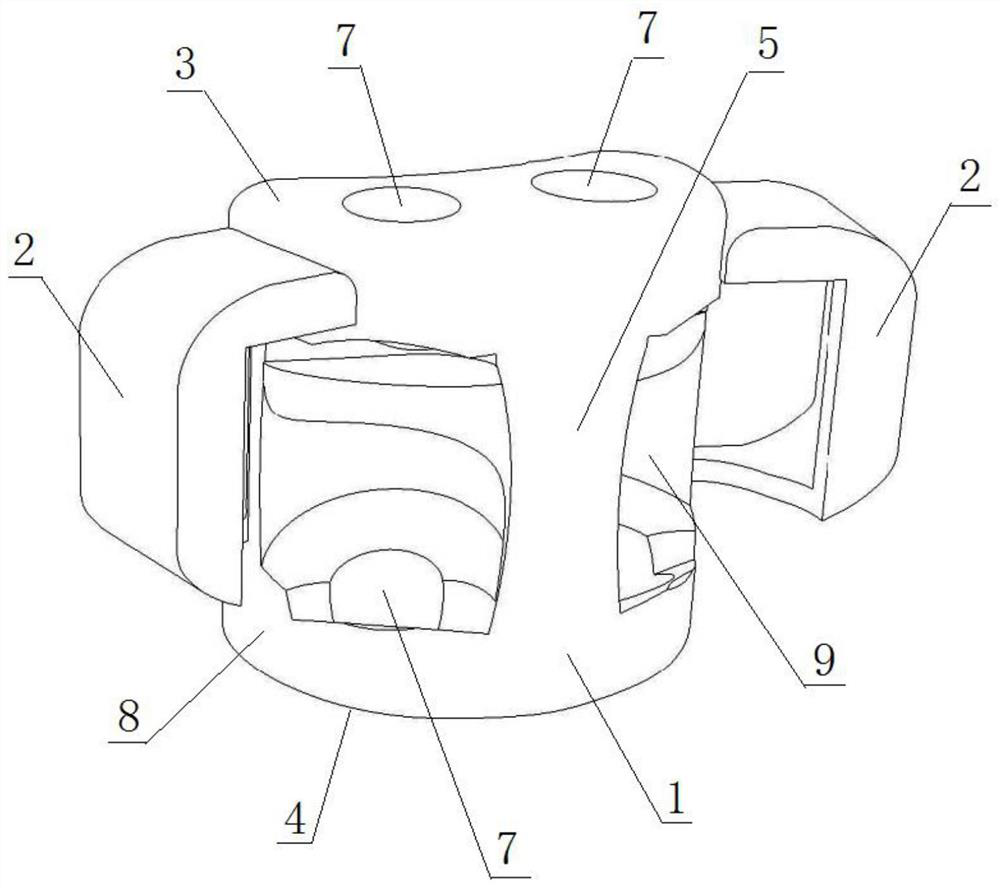

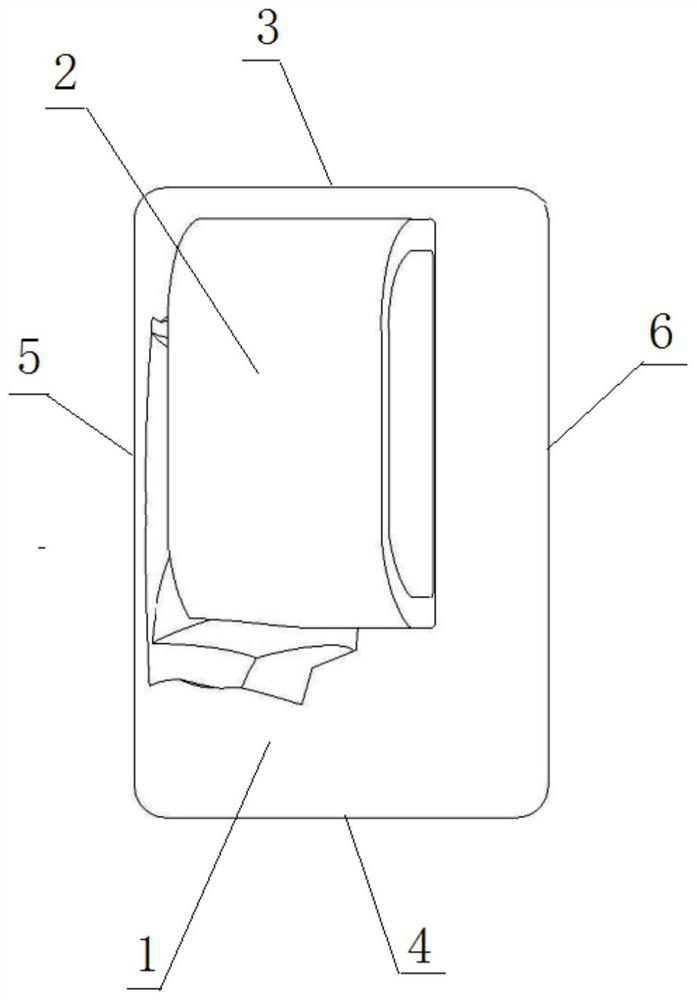

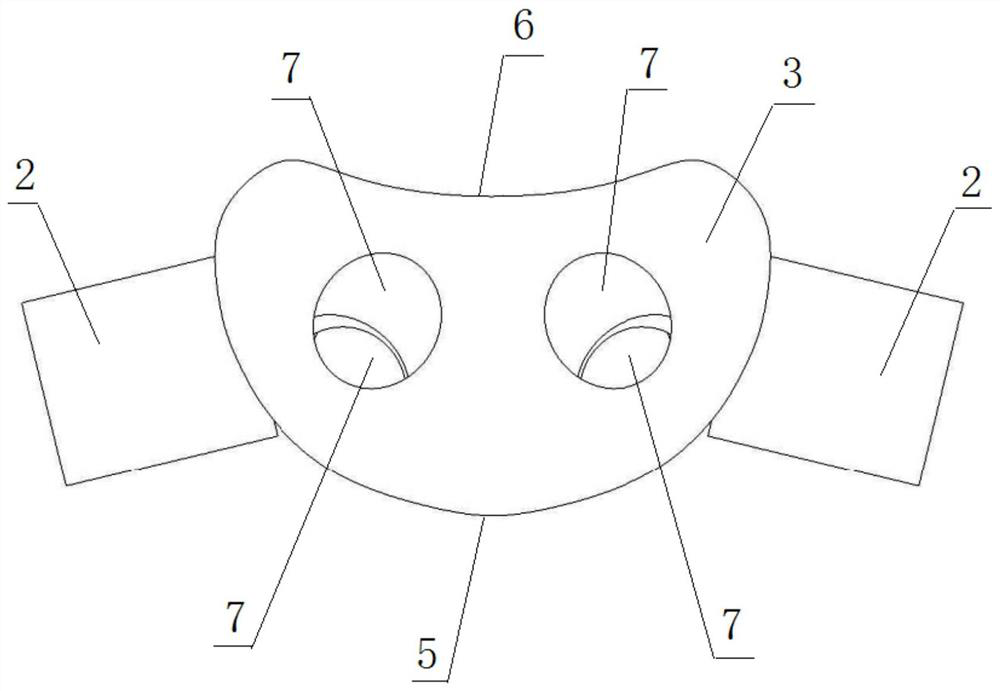

[0039] Such as figure 1 , figure 2 and image 3 As shown, a personalized artificial vertebral body implant based on additive manufacturing of the present invention includes an artificial vertebral body main body 1, and the artificial vertebral body main body 1 includes an inner pore layer 9 and an outer dense layer wrapping around the inner pore layer 9 8. The internal pore layer 9 is a lightweight pore structure with a porosity of 75% and a pore diameter of 500 μm. The upper end surface 3 of the inner pore layer 9 is provided with two nail holes 7, and the lower end surface 4 is provided with There are two nail holes 7 corresponding to the two nail holes 7 on the upper end surface 3, and the four nail holes 7 form two nail paths correspondingly up and down, and the thickness of the outer dense layer 8 is 3 mm.

[0040] The upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com