Active cooling type one-dimensional wave surface correction device

A technology of active cooling and wavefront correction, applied in optical components, optics, instruments, etc., can solve problems such as mirror thermal distortion, reduce additional surface changes, solve existing technical problems, and maintain the effect of beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

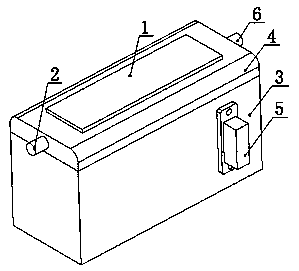

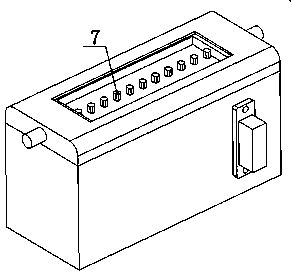

[0018] Such as figure 1 As shown, it is an active cooling type one-dimensional wave surface correction device of the present invention, including a base 3, the base 3 is made of Invar material, a cooling plate 4 is arranged on the top of the base, and a cooling cavity is arranged in the middle of the cooling plate 4; There is a row of through holes at the bottom of the cooling cavity, such as figure 2 As shown, a driver 7 passes through each through hole, and the gap between the driver 7 and the through hole is sealed with waterproof glue. The drivers 7 are arranged inside the base 3 , and each row of drivers 7 in the width direction is connected in parallel, and is connected to an external control system through the connector 5 on the base 3 to form a loop. The arrangement of the drivers 7 matches the shape of the one-dimensional wave surface that needs to be corrected, and each row of drivers in the width direction is connected in parallel and expands and contracts at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com