Mobile crushing system and mobile crushing system assembly

A crushing system, mobile technology, applied in the direction of grain processing, etc., can solve the problem of only small loading volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

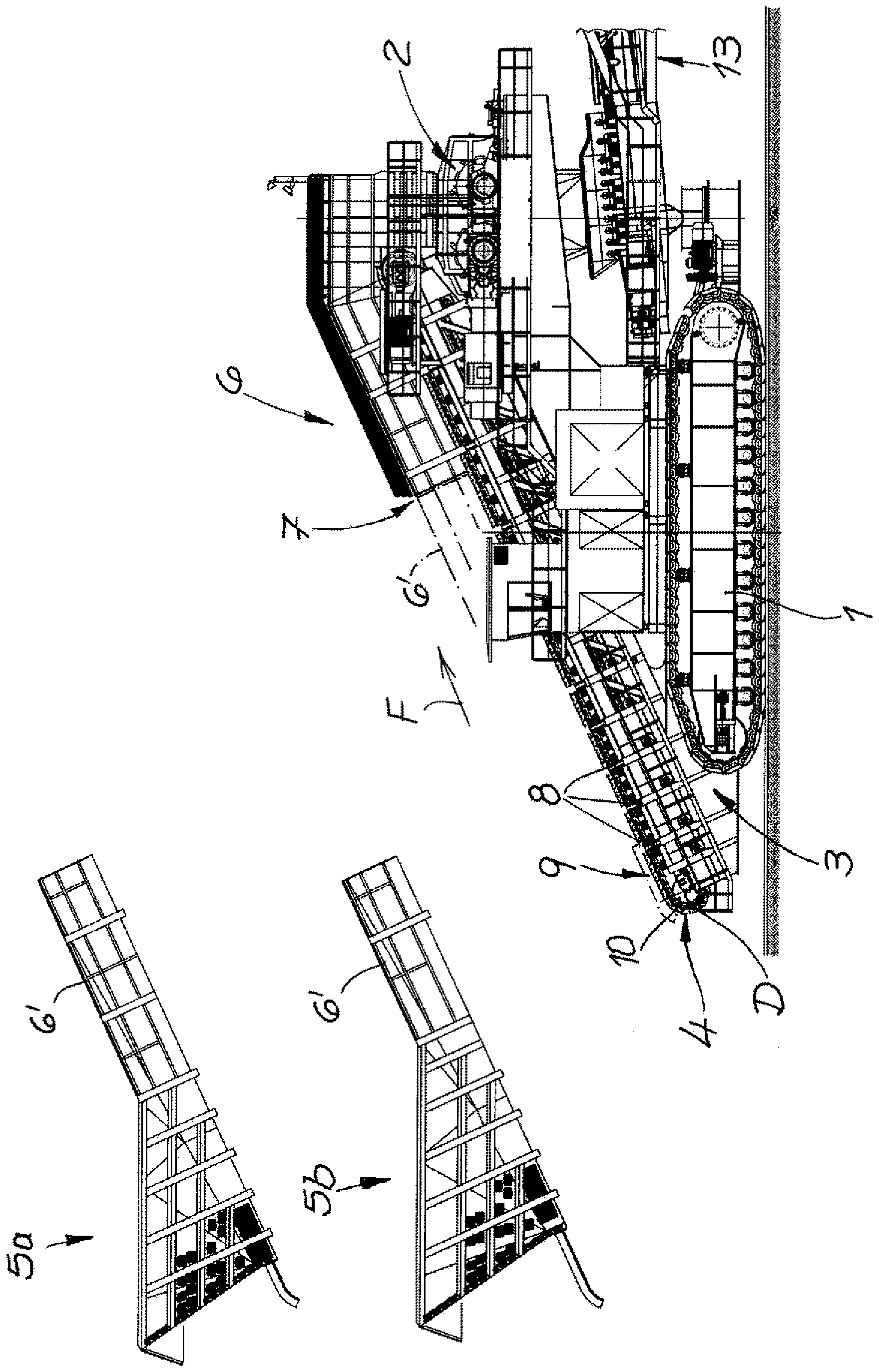

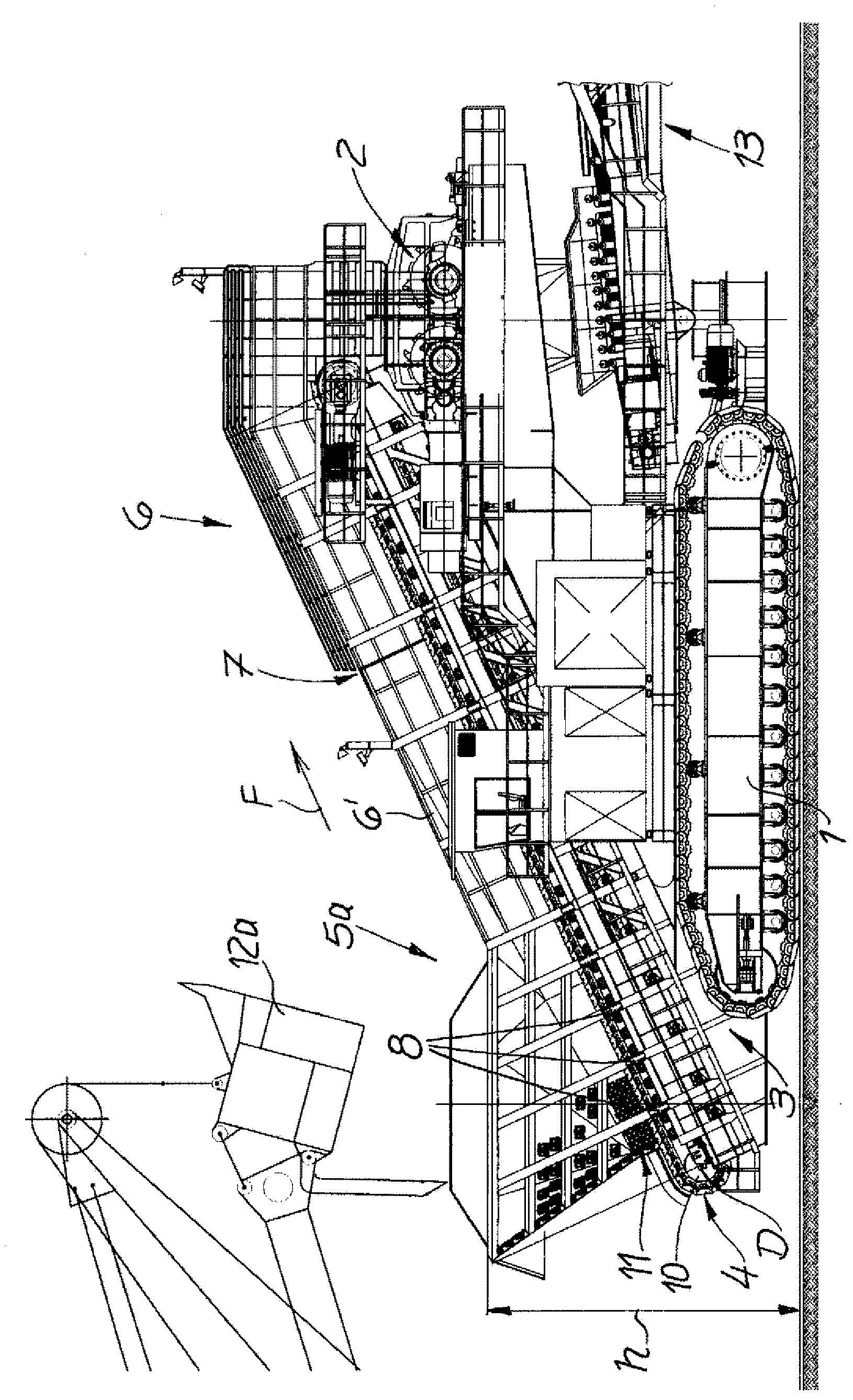

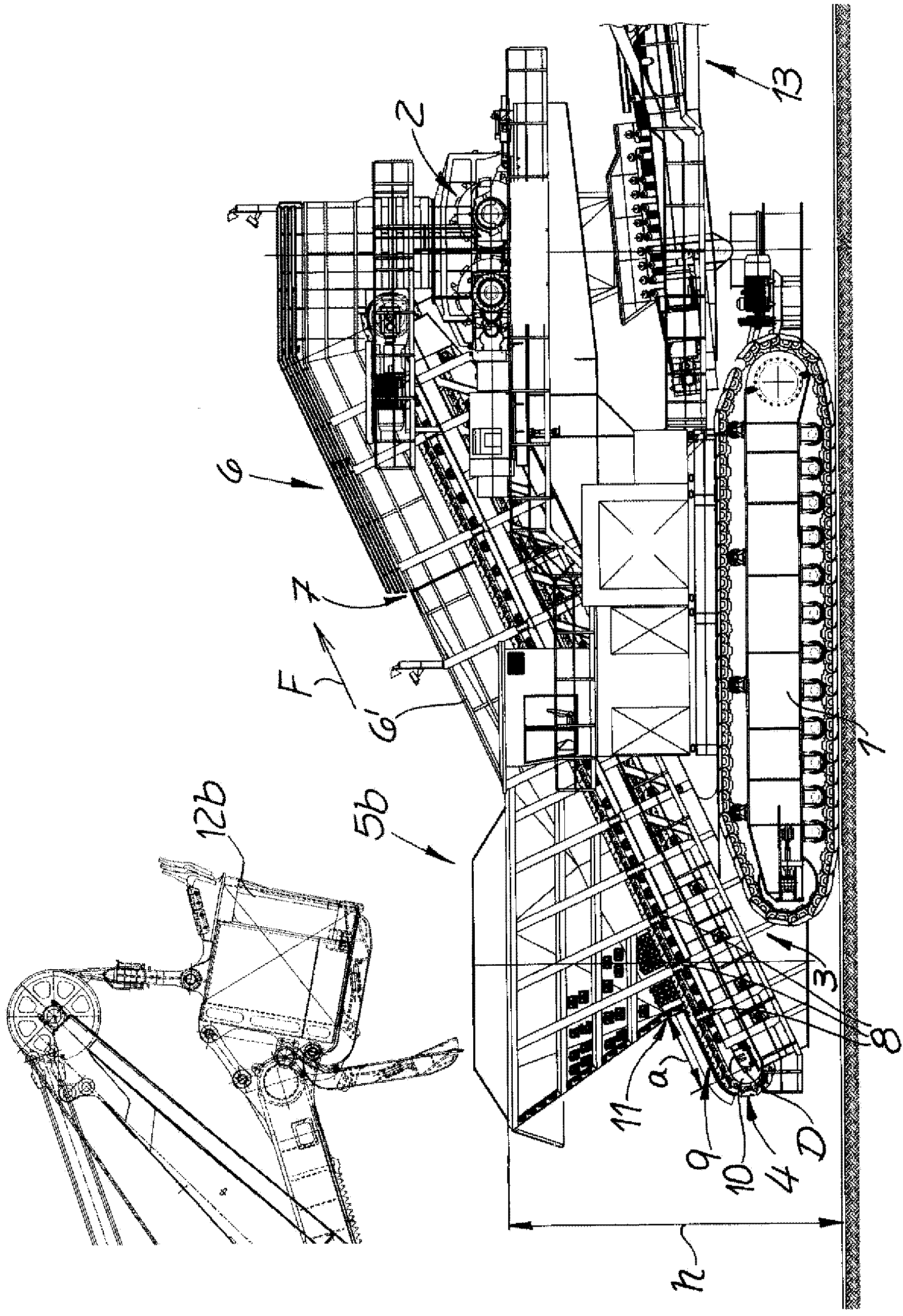

[0034] figure 1 A mobile crushing system assembly is shown comprising a chassis 1 , a crusher 2 and an apron conveyor 4 arranged on a support structure 3 .

[0035] According to the present invention, the mobile crushing system assembly includes a first hopper 5a and a second hopper 5b, and the first hopper 5a and the second hopper 5b are interchangeable as modules. To this effect, the two hoppers 5a, 5b are detachably fixed to the support structure 3, so that the hoppers 5a, 5b can be removed from the slatted conveyor 4 along a predetermined separating surface.

[0036] In the exemplary embodiment shown, the filling volume of the second hopper 5b is greater than the filling volume of the first hopper 5a. Since the second hopper 5b has a larger capacity, it can also be loaded by using a larger shovel 12b. During operation, the larger volume of the second hopper 5b results in a greater static load due to the inherent weight of the crushing system and the weight of the filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com