High-frequency signal transmission line and electronic equipment

一种信号线路、传输线路的技术,应用在高频匹配器、电路、印刷电路等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0039] (Structure of high frequency signal transmission line)

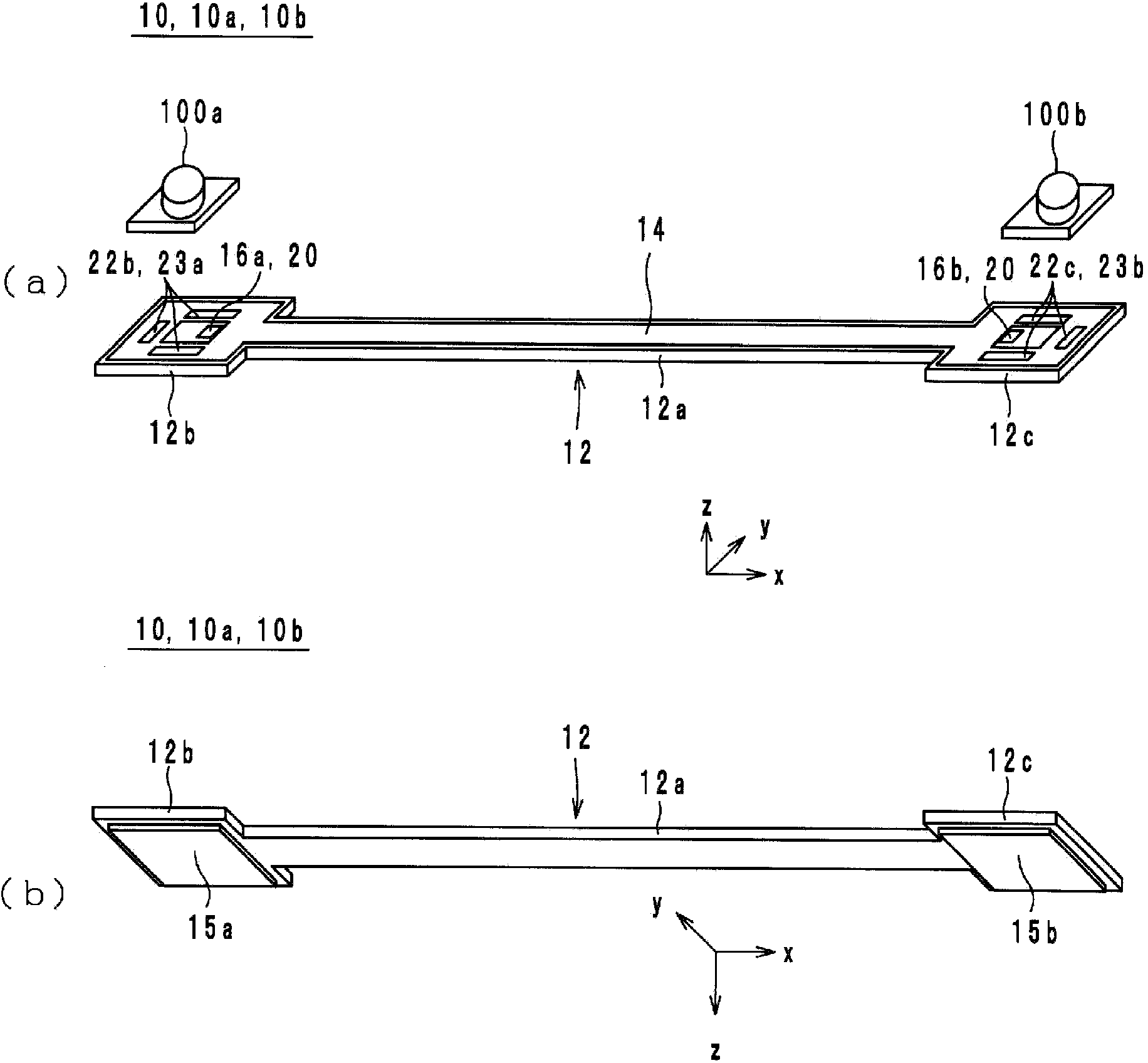

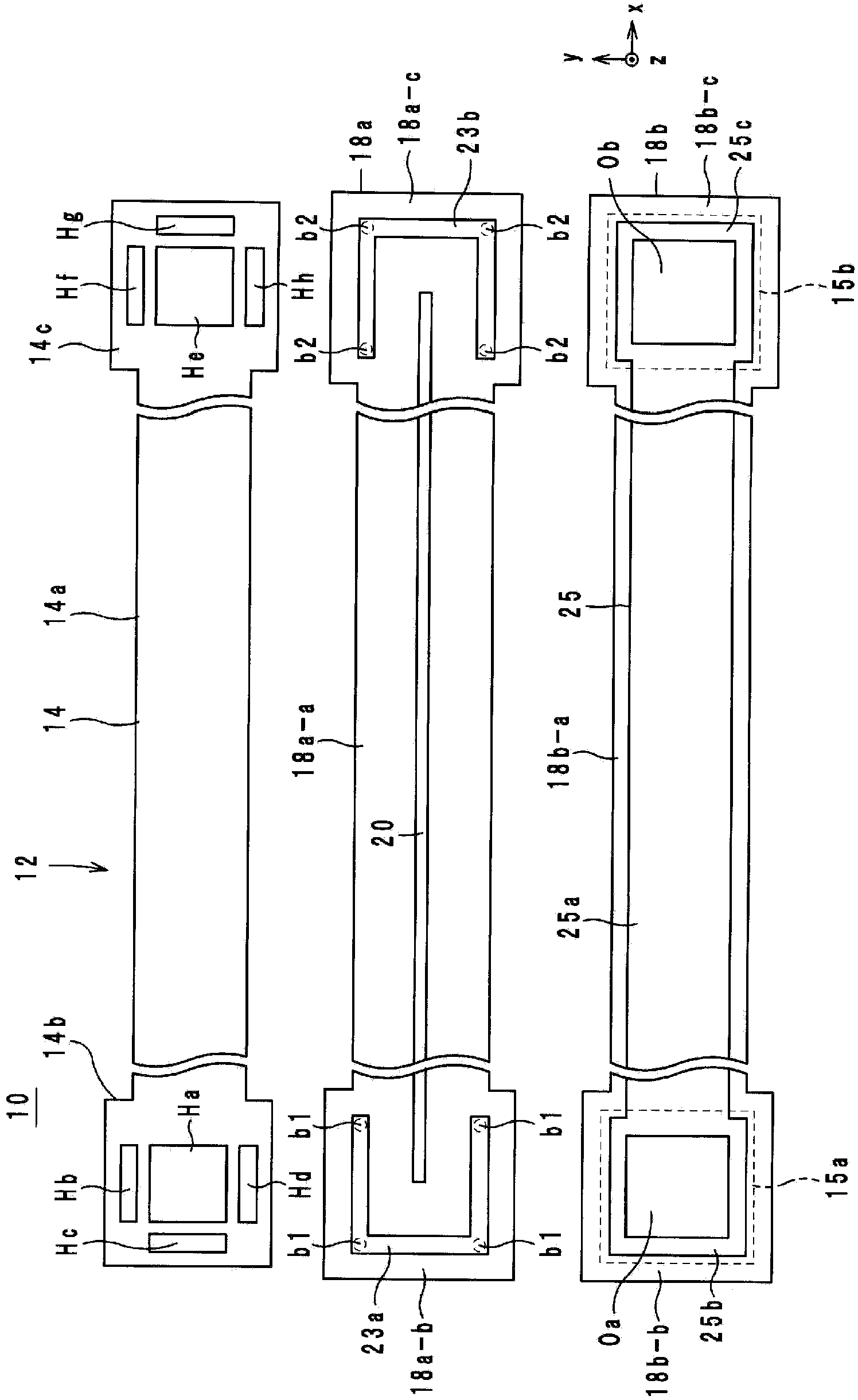

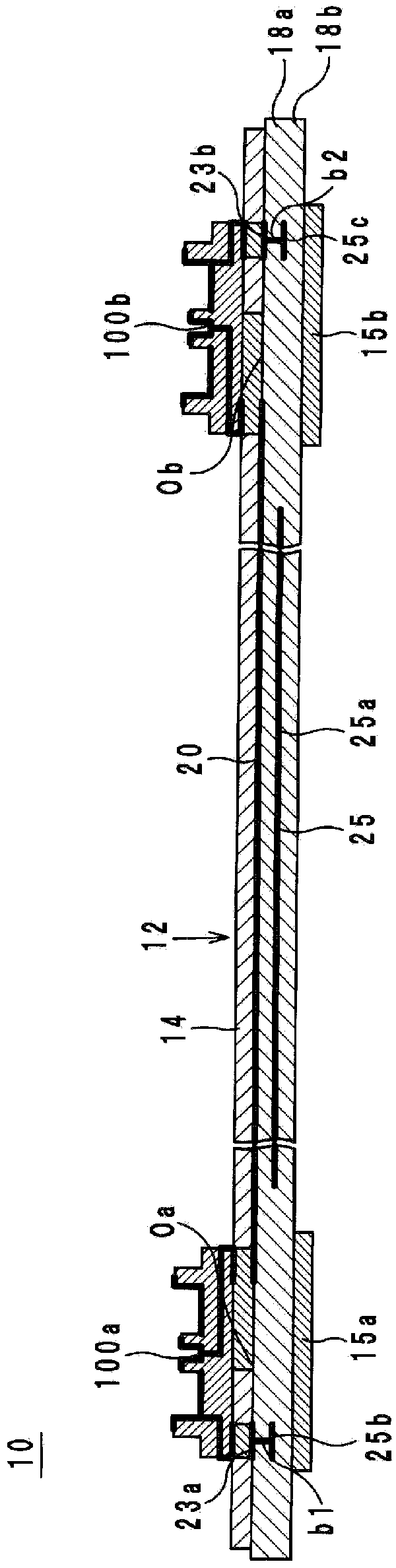

[0040] Hereinafter, the structure of the high-frequency signal transmission line according to Embodiment 1 of the present invention will be described with reference to the drawings. figure 1 It is an external perspective view of the high-frequency signal transmission line 10 according to the first embodiment. figure 2 It is an exploded view of the dielectric body 12 of the high-frequency signal transmission line 10 according to the first embodiment. image 3 It is a cross-sectional configuration diagram of the high-frequency signal transmission line 10 according to the first embodiment. Figure 4 It is an external perspective view and a cross-sectional structural view of the connector 100b of the high-frequency signal transmission line 10. in Figure 1 to Figure 4 Here, the lamination direction of the high-frequency signal transmission line 10 is defined as the z-axis direction. In addition, the longitudinal directio...

Embodiment approach 2

[0087] (Structure of high frequency signal transmission line)

[0088] Hereinafter, the structure of the high-frequency signal transmission line according to Embodiment 2 of the present invention will be described with reference to the drawings. Picture 9 It is an exploded view of the dielectric body 12 of the high-frequency signal transmission line 10a according to the second embodiment. Picture 10 It is a cross-sectional configuration diagram of a high-frequency signal transmission line 10a according to the second embodiment. Regarding the appearance perspective view of the high-frequency signal transmission line 10a, quote figure 1 .

[0089] Such as figure 1 with Picture 9 As shown, the high-frequency signal transmission line 10a includes a dielectric body 12, external terminals 16 (16a, 16b), connecting conductors 17 (17a, 17b), signal lines 20, ground conductors 22, 24, via-hole conductors b11 to b14, B1 to B6 and connectors 100a, 100b.

[0090] When viewed in plan from the...

Embodiment approach 3

[0131] (Structure of high frequency signal transmission line)

[0132] Hereinafter, the structure of a high-frequency signal transmission line according to Embodiment 3 of the present invention will be described with reference to the drawings. Picture 12 It is an exploded view of the dielectric body 12 of the high-frequency signal transmission line 10b according to the third embodiment. In addition, the external perspective view of the high-frequency signal transmission line 10b is cited figure 1 .

[0133] The main difference between the high-frequency signal transmission line 10b and the high-frequency signal transmission line 10a is that the ground conductor 24 is not provided. Hereinafter, a detailed description will be given centering on the difference.

[0134] Such as figure 1 and Picture 12 As shown, the external terminal 16a is a rectangular conductor disposed near the center of the surface of the connecting portion 18a-b. Such as figure 1 and Picture 12 As shown, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com