Polishing device and method for improving uniformity of chemical mechanical polishing by means of same

A grinding device and grinding machine technology, which is applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of difficulty in monitoring the thickness loss of the buckle, the negative impact of adjusting the grinding uniformity, and the fastening of the buckle, etc., to achieve improvement The chemical mechanical grinding uniformity, the effect of improving the grinding uniformity and reducing the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

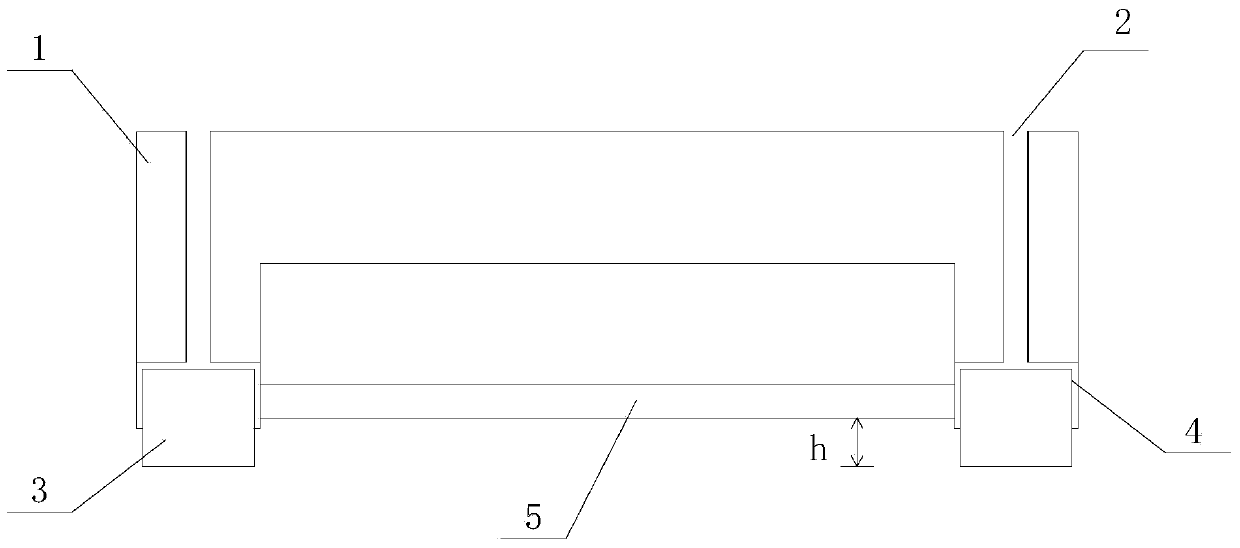

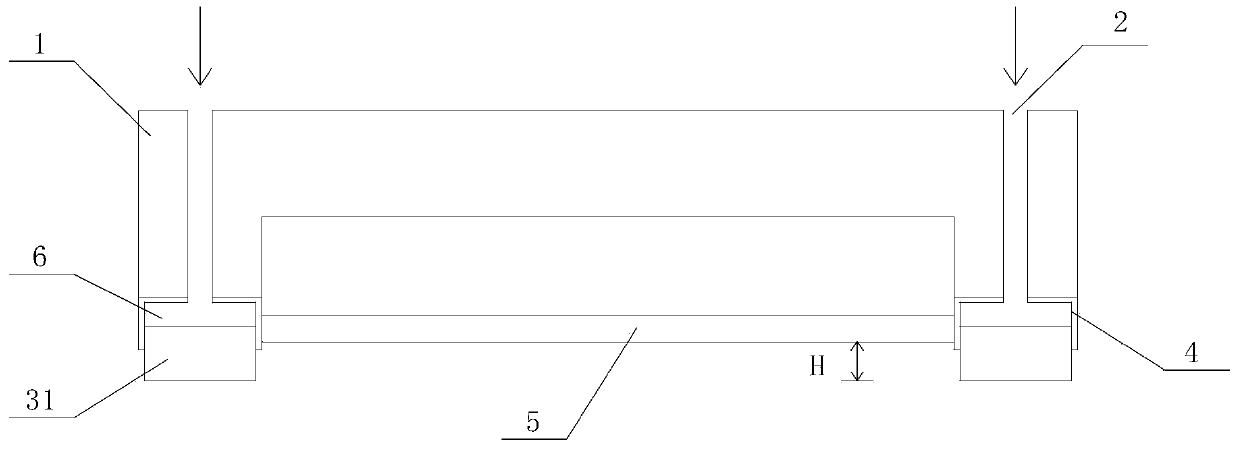

[0023] figure 1 It is a schematic structural diagram of a grinding device in an embodiment of the present invention, such as figure 1 Shown, a kind of grinding device is applied in the chemical mechanical grinding process, and this grinding device comprises the grinding machine table with grinding head 1, and the lower surface on this grinding head is provided with the groove 4, preferably can be along this grinding The edge of the card slot 4 is provided with a slot 4, and the opening end of the slot 4 is facing downward, and the bottom of the slot 4 is also provided with a through hole 2 that runs through the grinding head. Using an inflatable device, the through hole 2 can be used to enter the slot. 4 filled with gas.

[0024] Further, a bonded body 3 composed of a buckle ring and a circular steel ring is clamped in the slot 4, and a diaphrag...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap