Method and device for elevator car buffer braking under unsatisfactory stagnation conditions

An elevator car and buffer braking technology, which is applied in transportation, packaging, elevators, etc., can solve the problems of increased shaft load of the traction motor, increased car self-weight, and increased car self-weight to achieve safety protection , to prevent the effect of the top rush accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

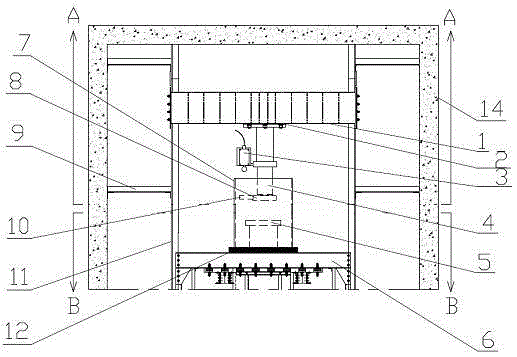

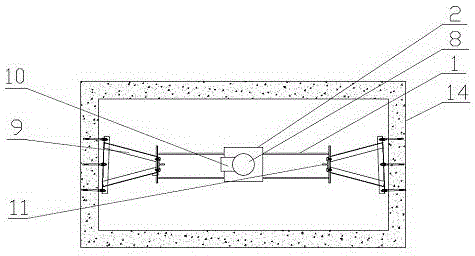

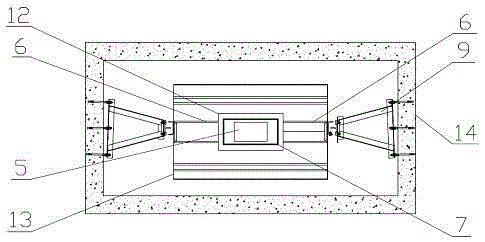

[0033] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing and embodiment:

[0034] The elevator in this embodiment is driven by a traction motor. The elevator car and the counterweight are respectively suspended at both ends of the traction wire rope bypassing the traction sheave. The ratio of the pulling force on the wire rope is T 1 / T 2 , when T 1 / T 2 ≥e fα , meet the requirements of the elevator safety detention working condition, and the buffer braking method of the elevator car under the unsatisfactory detention working condition includes: the top of the elevator shaft where the elevator is running corresponds to the elevator car running to the top of the elevator shaft to set an elevator buffer and an action detection switch for detecting whether the elevator buffer is in motion; the top of the elevator car is provided with a buffer bumper, and the wiring circuit of the action detection switch is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com