Manufacturing method of chain saw type track slag removal machine

A manufacturing method and technology of slag removal machine, applied in the direction of track, road, ballast layer, etc., can solve the problems of slow operation speed, unsuitable for modern railway maintenance needs, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

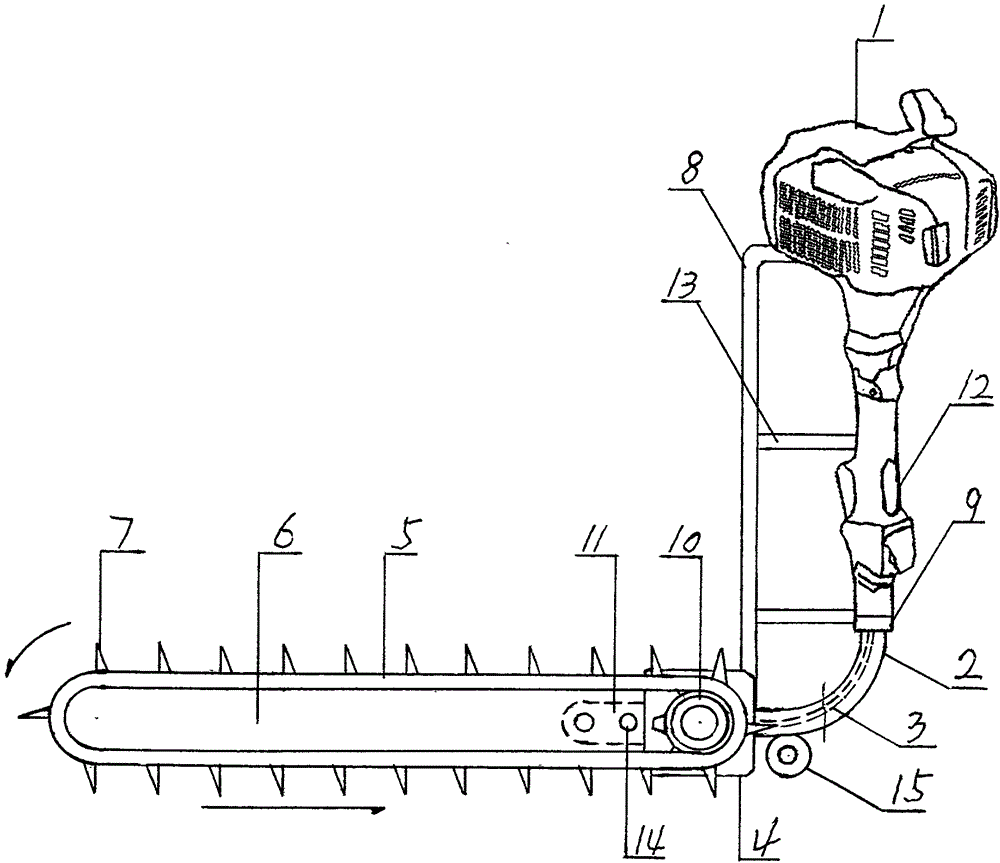

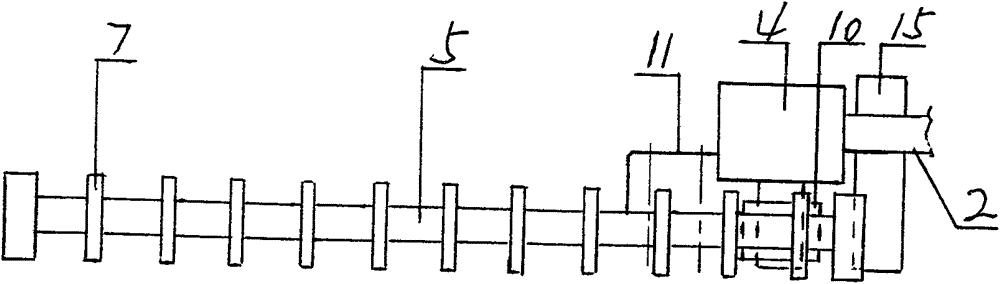

[0007] Such as figure 1 , 2 Shown is a manufacturing method of a chainsaw-type track slag removal machine, which replaces manual slag removal operations; the machine is modified by using a high-branch chainsaw (patent number: 201120226493.2). The modified parts are the transmission shaft and the following parts. The modified structure is composed of gasoline engine, bent pipe, flexible shaft, turbine chamber, sawtooth chain, guide plate, pick and handle. The method is: remove the original transmission shaft and the following parts, and connect a section of elbow 2 on the base 9 of the transmission shaft. One. A section of flexible shaft 3 is installed in the elbow 2, and the two ends of the flexible shaft 3 are respectively connected with the power output shaft of the gasoline engine 1 and the power input shaft of the turbine chamber 4 to form a whole. In this way, the power of the gasoline engine 1 is transmitted to the turbine chamber 4, and the turbine chamber 4 adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com