Detachable load-bearing support frame

A support frame and support rod technology, applied in the field of support frames, can solve the problems of large floor space, inconvenient use, low transportation efficiency, etc., and achieve the effects of improving transportation efficiency, reducing storage area and fast assembly speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

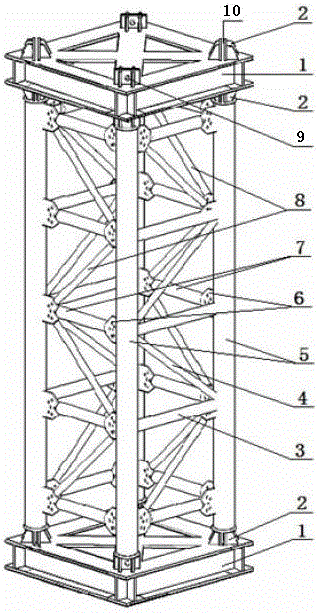

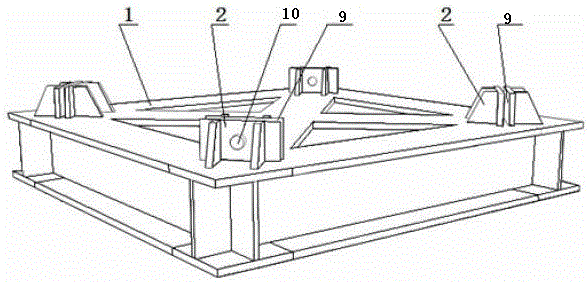

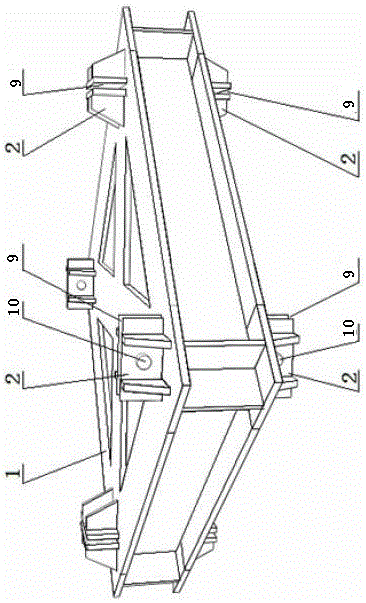

[0013] See attached Figure 1-5 , the number 1 in the figure is a square base, 2 is a support base, 3 is a fixed cross bar, 4 is a fixed slant bar, 5 is a support bar, 6 is a connecting plate, 7 is a movable cross bar, 8 is a movable slant bar, and 9 is Mounting groove, 10 and 11 are latch holes, 12 is a mounting plate, and 13 is a support rod connector.

[0014] The accompanying drawings disclose a non-restrictive structural diagram of an embodiment of the present invention, which is further described in conjunction with the accompanying drawings as follows:

[0015] The detachable load-bearing support frame of the present invention, such as figure 1 As shown, its structure includes a square base 1, a support plate, a movable cross bar 7 and a movable diagonal bar 8, wherein the support plate is composed of two support bars 5 and fixed cross bars 3 and fixed inclined bars distributed between the support bars. The rod 4 is welded, and the support rod 5 is welded with a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com