An installation method for hydraulically filling flexible water filter pipes in underground mined-out areas

A technology of hydraulic filling and installation method, which is applied in the direction of filling, mining equipment, safety devices, etc., can solve the problems of difficult construction of water filter pipes, achieve the effects of improving installation efficiency and operation safety, solving difficult construction, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

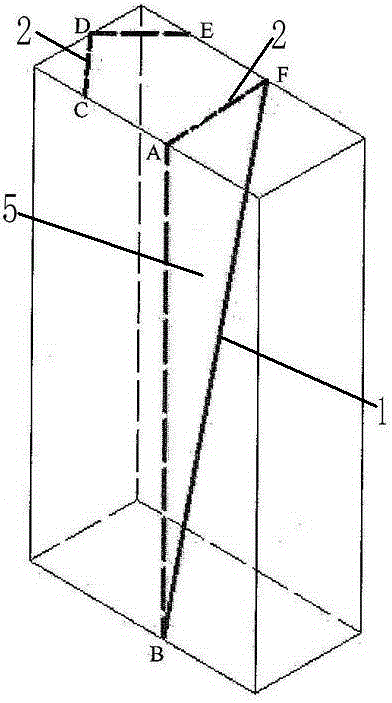

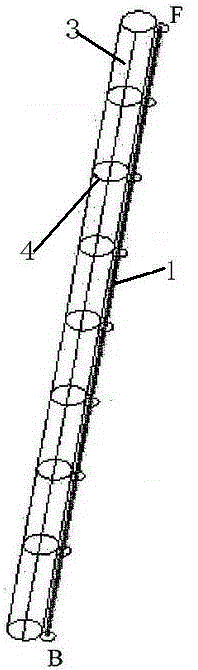

[0016] see figure 1 and figure 2 as shown,

[0017] Method of the present invention comprises the following steps:

[0018] 1) Construct a ground anchor at a safe and firm location 10m away from point A and point F, for hanging the safety rope, main rope 1 and auxiliary rope 2.

[0019] 2) Lower the main rope 1 vertically from point A to point B, fix the lower end of the main rope 1 on the stable rock wall of the lower and middle section of the mine exit with expansion bolts, and temporarily fix the upper end of the main rope 1 on the ground anchor near point A superior.

[0020] 3) Throw the auxiliary rope 2 from point C to point D, and then throw it from point D to point E, and then pull the end of auxiliary rope 2 from point E to the ground anchor near point F for temporary fixation. Because both CD and DE are small hypotenuses at the 5 corners of the goaf, they can be easily thrown by manpower to achieve the goal.

[0021] 4) Pull the head end of the auxiliary rope 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com