All-geographic lifting farmland pipeline irrigation multi-functional water supply hydrant

A lift-type, water supply hydrant technology, applied in the field of agricultural irrigation, can solve the problems of inability to measure water to households, affecting agricultural machinery farming, inconvenient project management, etc., and achieve the effect of solving the problem of water metering to households

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

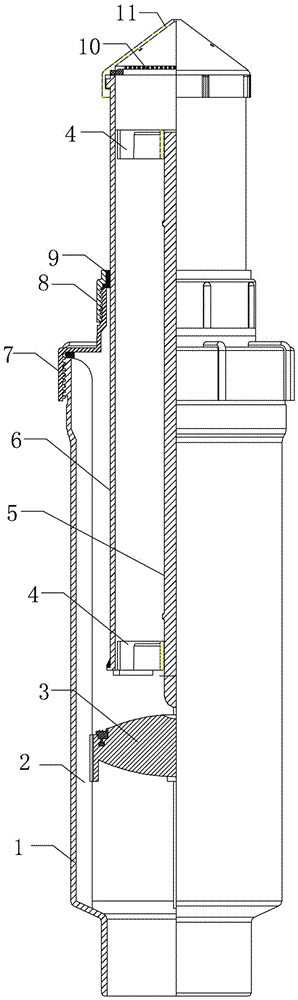

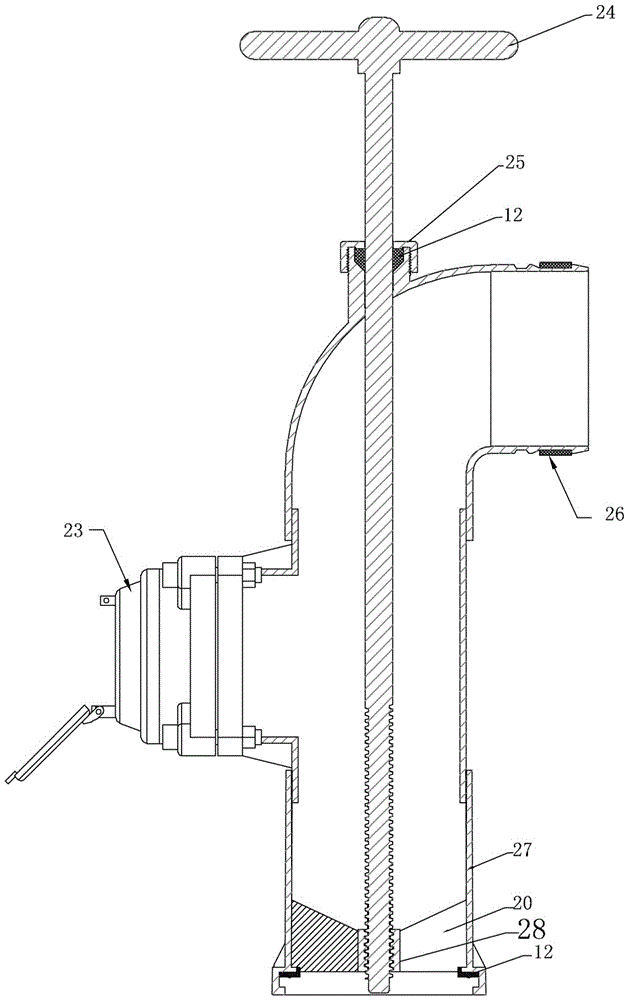

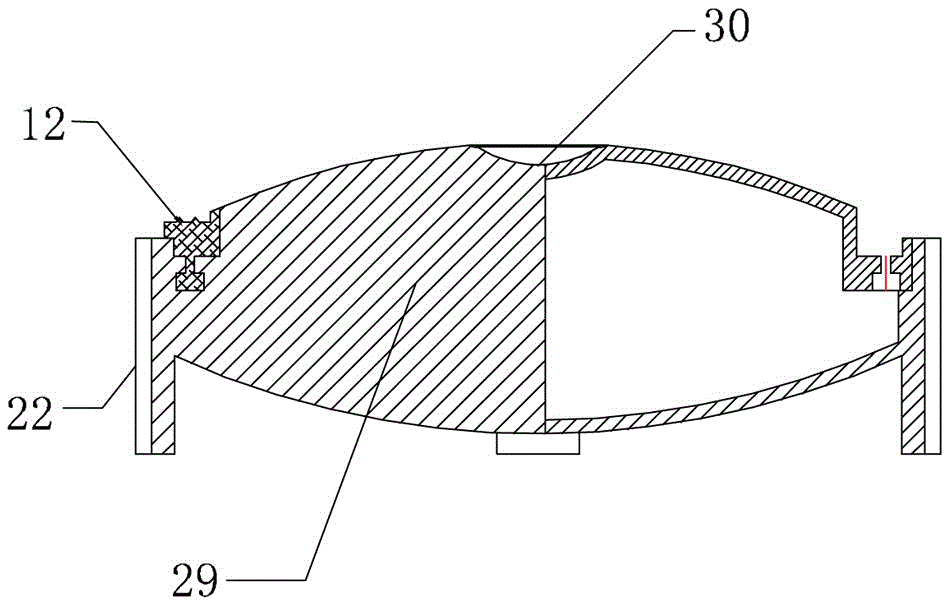

[0044] As shown in the figure: the water supply hydrant adopts a semi-fixed split combination structure, the lower cock body is placed below the ground cultivation layer (30 cm below the ground), and is connected with the pipe tee to form a fixed device for supplying water to the field without concrete The protection of the pipe device completely solves the problem of affecting cultivation; the lower bolt body adopts piston-type lifting technology, which is hidden under the ground tillage when it is not irrigated, and automatically rises out of the ground when it is irrigated; the upper bolt body is matched with the lower bolt body, and the bottom of the upper bolt body The cross support rib 20 and the opening drive nut 29 are set to form a special tool for pushing the floating body downward and opening the lower bolt body; the inner side of the outer casing 1 is provided with a slideway 2, and the floating body water stop valve 3 is installed on the slideway 2 of the outer casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com