A Replaceable Installation Method of Embedded Vibrating Wire Strain Gauge

An installation method and a technology of strain gauges, which are applied in the direction of measuring devices and instruments, can solve the problems of no embedded vibrating wire strain gauges, etc., and achieve the effect of convenient, reliable and low-cost replacement of strain gauges and wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

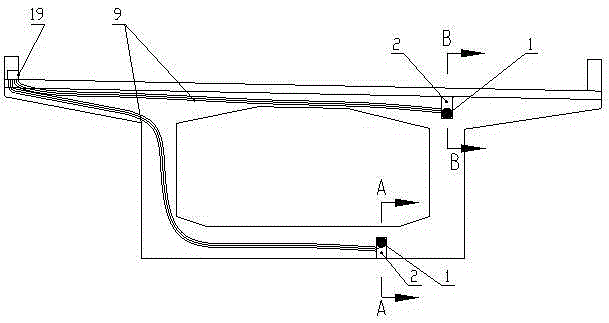

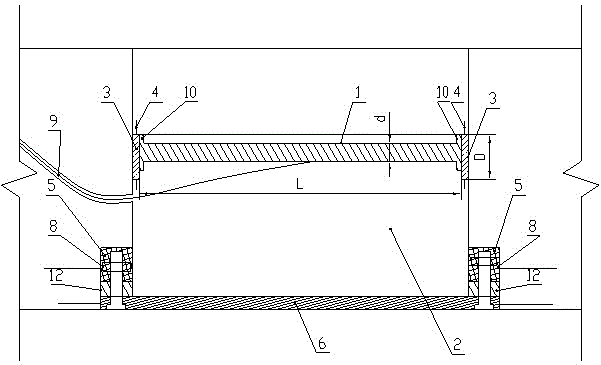

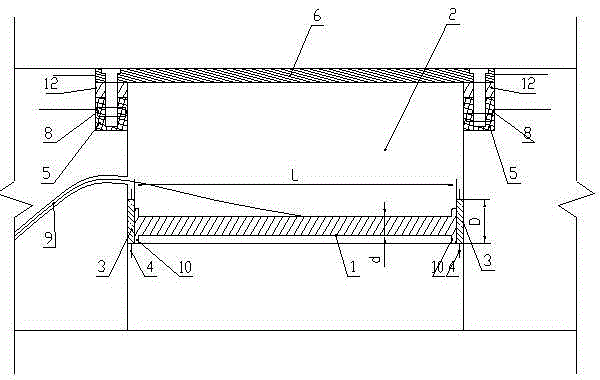

[0036] Such as figure 1 As shown, the installation method of the present invention is aimed at the vibrating wire strain gauge, and the vibrating wire strain gauge can be used to measure the stress change of the top plate, bottom plate and web of the beam. Its shape is dumbbell-shaped, and its structure is a cylinder in the middle, and the two ends of the cylinder are integrally connected with metal discs 10. The diameter of the metal disc 10 is D, and the diameter D of the metal disc 10 is greater than the diameter d of the cylinder.

[0037] The specific installation steps are:

[0038] 1. First select the model of the vibrating wire strain gauge, determine the length L of the strain gauge, and the diameter D of the metal disc 10 at both ends;

[0039] 2. Determine the point where the strain is to be measured, determine the position of the top or bottom plate, and measure the distance H between the vibrating wire strain gauge and the outer surface of the concrete;

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com