Monitoring device for positive/ shearing stress of bonding interface of solid rocket engine

A technology of solid rocket and monitoring device, applied in the direction of measuring device, measuring force, instrument, etc., can solve problems such as monitoring of debonding of solid motor bonding interface, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

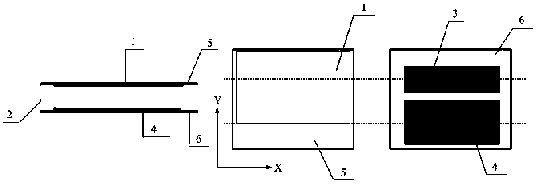

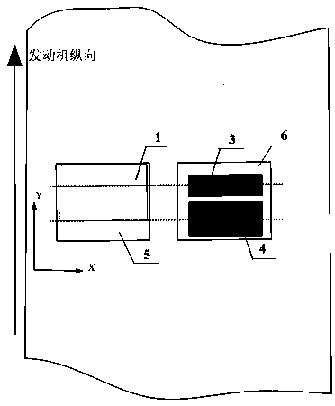

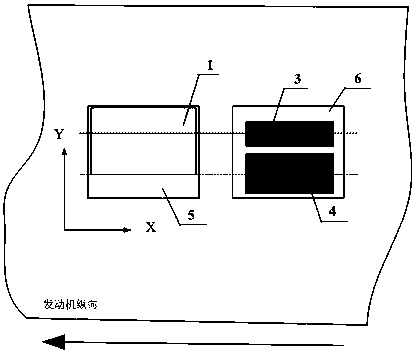

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0037] A monitoring device for the normal / shear stress of the solid rocket motor bonding interface of the present invention includes a normal / shear stress sensor as the core, combined with the sensor embedding method, process, wire lead-out, flange plate design, sensor layout and other content.

[0038] The present invention is based on the structural layout of a typical solid rocket motor, wherein: the interface stress sensing element adopts a capacitive sensor 7 that can realize simultaneous monitoring of normal shear stress. Layer thickness and shell material are mainly divided into three types of implantation methods, such as Figure 6-8 As shown, the sensor 7 and the data acquisition instrument 19 are connected by a weather-resistant ultra-thin wire, and the wiring method is divided into two ways: the wiring under the lining layer 11 and the wiring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com