Gamma voltage drive circuit, source drive module and liquid crystal display panel

A voltage-driven, source-driven technology, applied in the direction of instruments, static indicators, etc., can solve the problems of increasing cost, increasing the difficulty of driver IC design and manufacturing process, etc., to reduce the number of uses, reduce the difficulty of design and manufacturing process , The effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

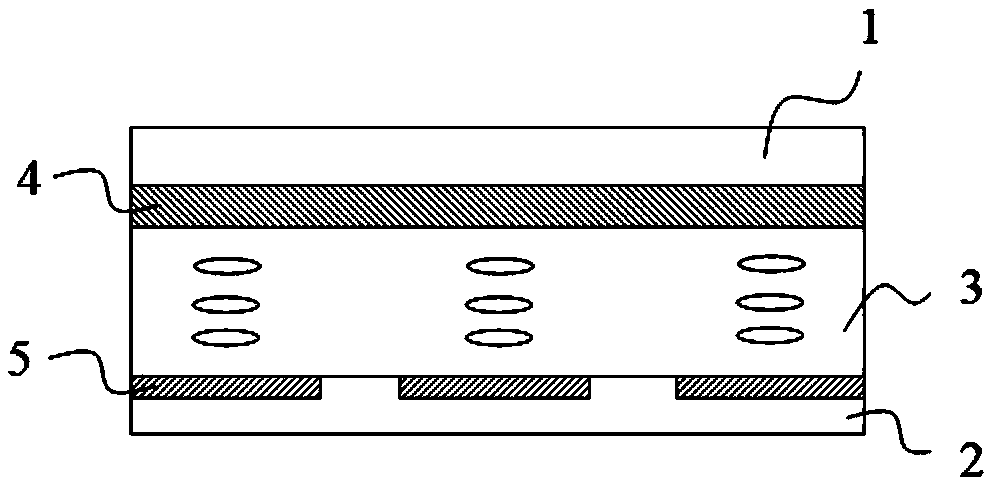

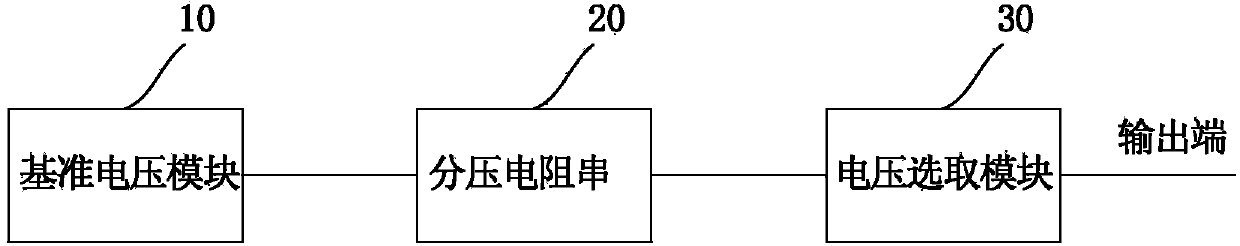

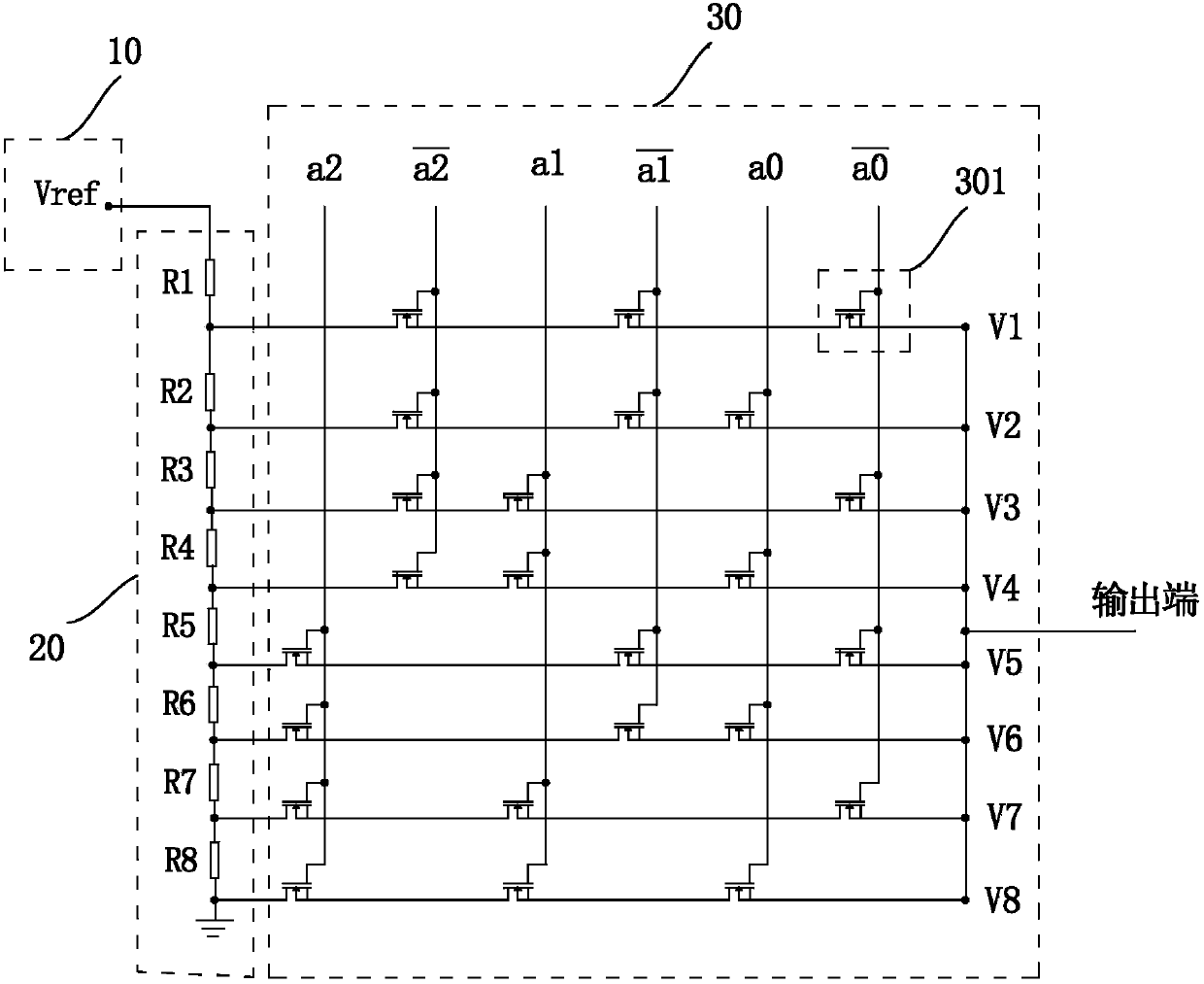

[0030] As mentioned above, in order to solve the problems existing in the prior art, the present invention provides a Gamma voltage driving circuit, which includes: a reference voltage module, which provides a reference voltage to the voltage dividing resistor string; of 2 n resistors to divide the reference voltage into 2 n Gamma voltages; wherein, n is an integer not less than 1; the voltage selection module is used to select and output the 2 n One of the Gamma voltages;

[0031] Wherein, the reference voltage module includes a first reference voltage and a second reference voltage, the first reference voltage is coupled to one end of the voltage-dividing resistor string, and the other end of the voltage-dividing resistor string is connected to ground; The second reference voltage is coupled to the first voltage dividing resistor string with the first Between resistors, wherein the voltage value of the second reference voltage is equal to that of the first reference vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com