Tire information acquisition apparatus, tire state monitoring system, and method of collecting puncture repairing fluid

A technology for obtaining devices and repair fluids, which is applied in tire measurement, tire inflation valves, tire parts, etc., can solve problems such as the inability to recycle flat tire repair fluids, and achieve the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

[0111] Refer below Figure 12 and Figure 13 , right with Figure 5 An example (Modification 1) of the through hole 130 in which the shown through hole 130 is different will be described.

[0112] Such as Figure 12 and Figure 13As shown, the cross-sectional area of the through hole 130 of the tire valve 104 can be increased from the case side opening 130a to the outside opening 130b, and a hole protruding from the inner wall surface and extending along the through hole is provided on the inner wall of the through hole 130 . 130 steps extending in the connecting direction. In this case, the height H of the step is preferably 1 mm or less. In addition, if Figure 12 As shown, when the step is formed in such a manner that the hole cross-sectional area of the through hole 130 of the tire valve 104 becomes gradually larger from the case side opening 130a to the outer opening 130b, the pipe 20 inserted into the through hole 130 can be inserted along the surface of the st...

Deformed example 2)

[0115] Figure 14 (a), (b) are pairs and Figure 5 An example (Modification 2) of the communicating hole 126 different from the illustrated communicating hole 126 is illustrated. Figure 14 (a), the cross-sectional shape of the communicating hole 126 shown in (b) and Figure 5 The illustrated cross-sectional shape of the communication hole 126 is different.

[0116] Such as Figure 14 As shown in (a) and (b), the extending direction of the communication hole 126 at the cavity region side opening 126a of the communication hole 126 ( Figure 14 (a), (b) E2 direction) can be formed so that it may be directed outward in the tire radial direction. At this time, the tube 20 inserted into the tire valve 104 is guided to extend outward in the tire radial direction from the cavity region side opening 126 a via the through hole 130 and the communication hole 126 . As a result, the tube 20 can be easily inserted outside the tire cavity region in the tire radial direction, so that th...

Deformed example 3)

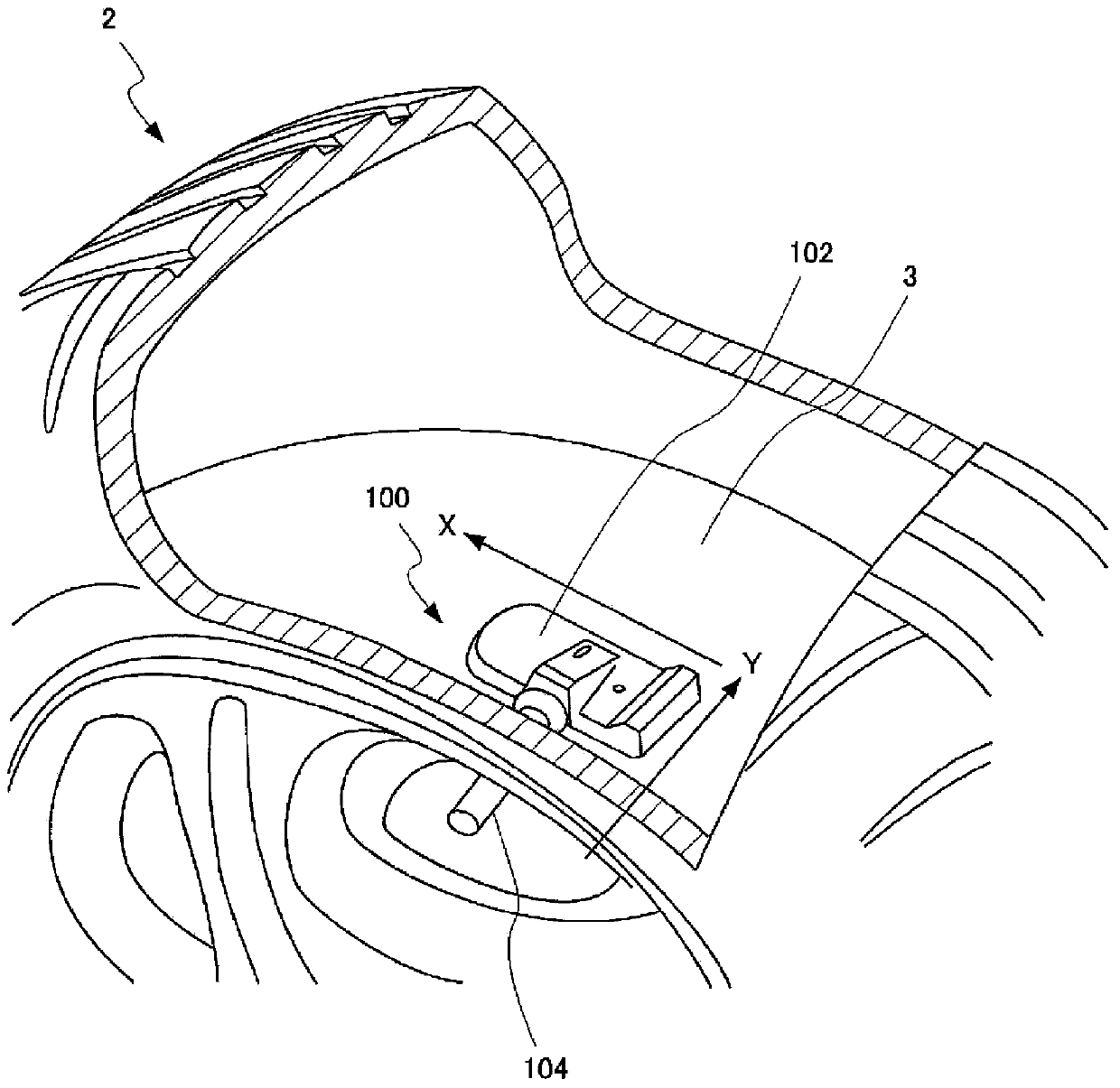

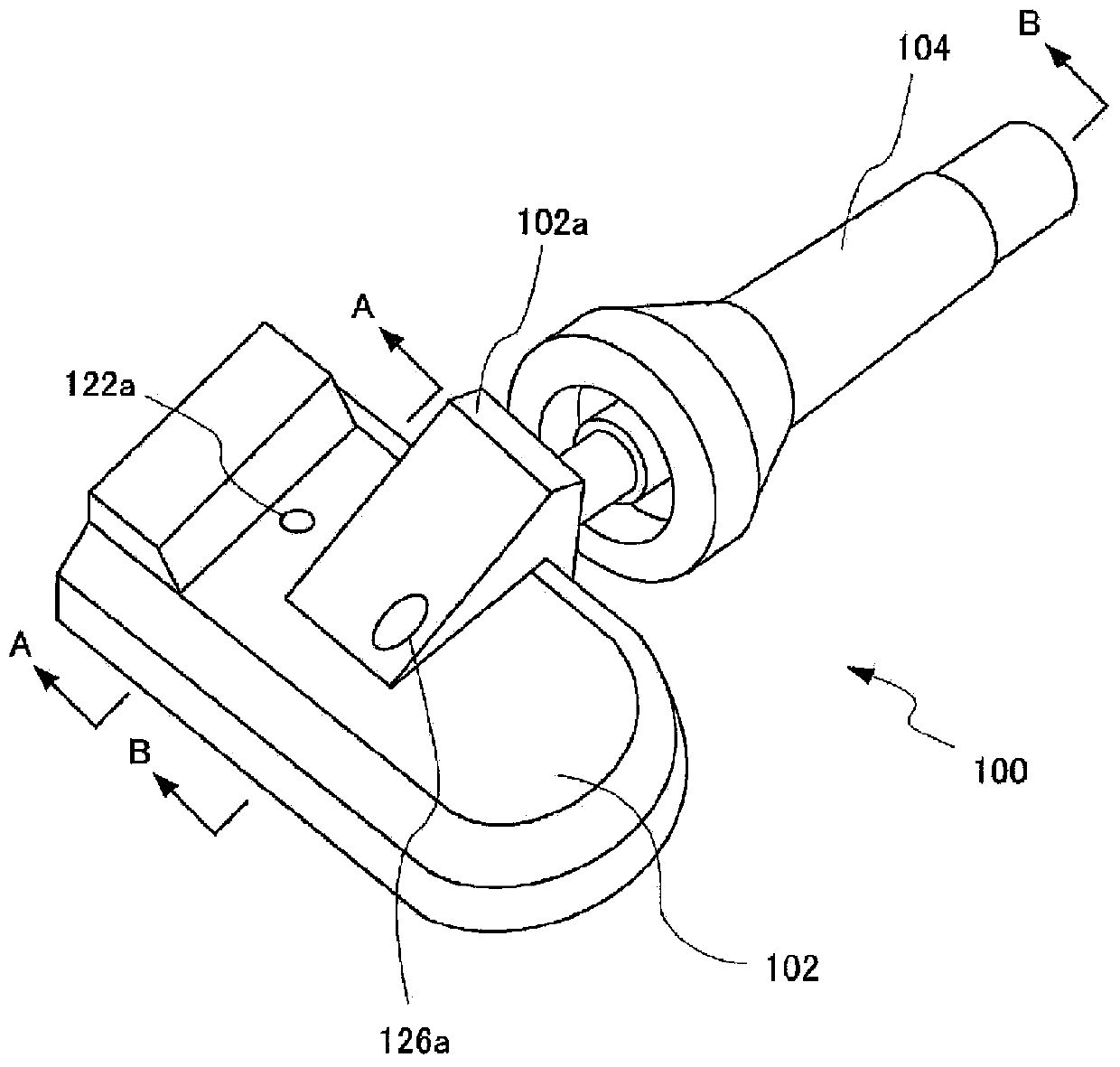

[0120] Figures 15-17 It is a figure explaining another example (modification 3) of the acquisition device 100 different from the above-mentioned embodiment. Figures 15-17 The acquisition device 100 shown is different from the acquisition device 100 of the above-mentioned embodiment in that a detachable mechanism for detachably holding the through portion 128 of the tire valve 104 inserted into the communication hole 126 is provided on the case 102 .

[0121] By making the space between the case 102 and the tire valve 104 detachable, for example, even if the tire valve 104 is adhered to the tire valve 104 by the puncture repair fluid 4 during puncture repair, only the tire valve 104 can be removed and replaced with a new tire valve.

[0122] Figure 15 It is a figure explaining an example of the modification 3. exist Figure 15 The shown penetration portion 128 has a male thread formed on the outer peripheral surface, and a female thread is formed on the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com