A kind of method for setting the moisture value of drying silk inlet

A technology of inlet moisture and setting value, which is applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of extremely difficult control of moisture value in cigarettes and difficulty in determining the moisture value of brand cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

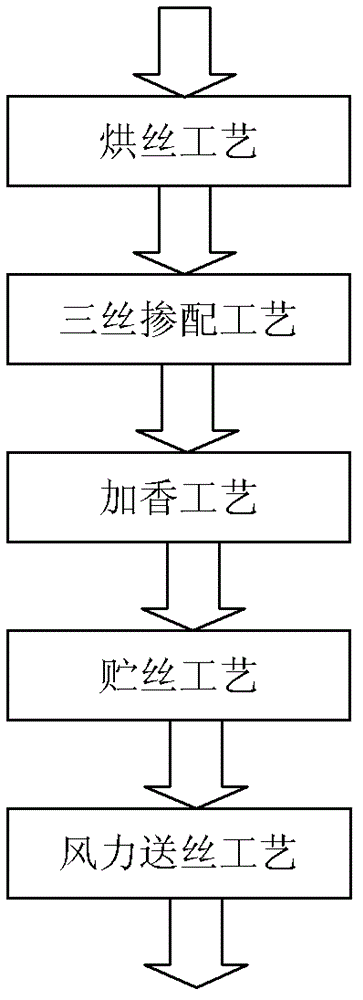

[0014] Such as figure 1 Shown, a kind of method for setting the moisture setting value of drying silk entrance, it comprises steps:

[0015] 1) Set the ambient temperature T, air relative humidity R, and production equipment altitude H, and the parameters of the ambient temperature T, air relative humidity R, and production equipment altitude H remain constant during the cigarette processing process. Since changes in the above parameters in each process of cigarettes will seriously interfere with the determination of the weight percentage of moisture in the entire process, once the appropriate temperature, humidity, and altitude of the production equipment are confirmed, the parameters will be kept constant throughout the entire production process.

[0016] 2) Measure the weight percentage value of moisture in shredded tobacco at each node, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com