A fixture structure for plunger chute machining

A specific structure and fixture technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of measuring chute scrapping of gauges, high design and manufacturing costs, and out-of-tolerance gauge dimensions, so as to achieve adjustability and processing The effect of short time and reduced clamping frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

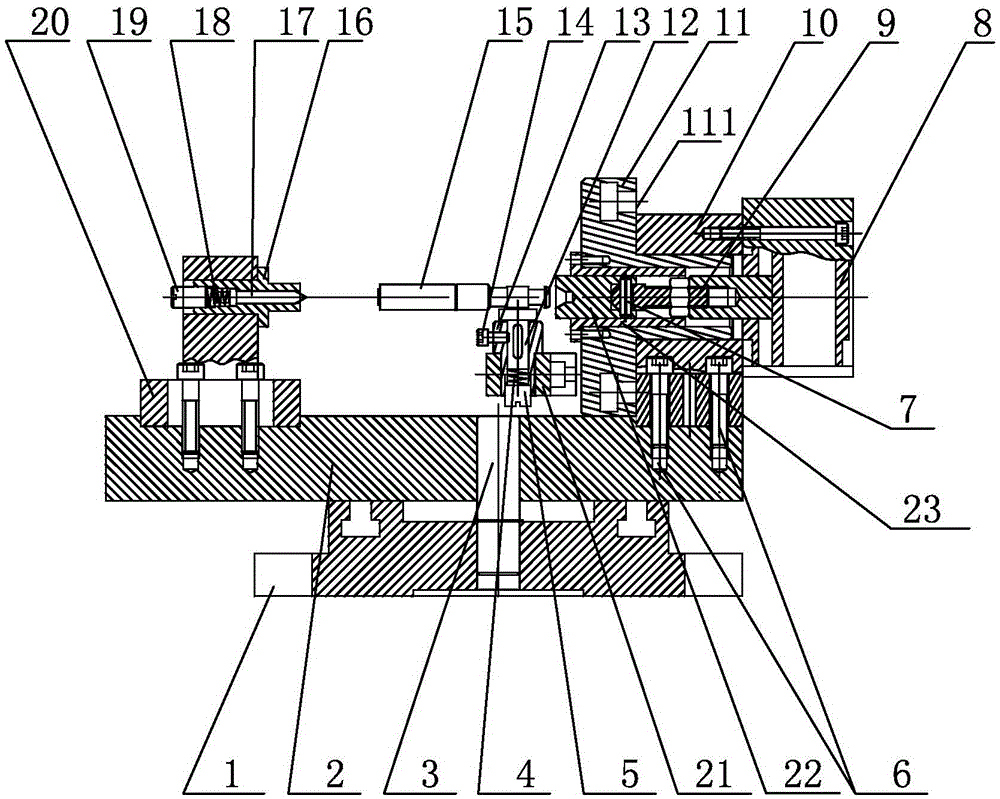

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] like figure 1 As shown, a fixture structure for plunger chute processing includes a chassis 1, and the chassis (1) is positioned and connected with the positioning round pin 3 of the bottom plate 2, and the first top mechanism and the clamp mechanism are respectively fixed on the bottom plate 2. The two top mechanisms are installed inside the clamp mechanism, and a positioning mechanism is also installed on the clamp mechanism;

[0027] The specific structure of the clamp mechanism is as follows: it includes a clamp body 10 affixed to the base plate 2 through a fastener 6, one end of the clamp body 10 is connected to the cylinder 8, and the other end of the clamp body 10 is connected to the boss end surface 111 of the dial 11 abutting against each other, one end of the dial 11 extends outward and extends into the clamp body 10;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com