High-precision circular contour dimension measurement algorithm based on non-uniform discrete data

A technology of discrete data and circular contours, applied in the field of signal processing, can solve problems such as inability to meet measurement requirements, and achieve the effect of improving dimensional measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

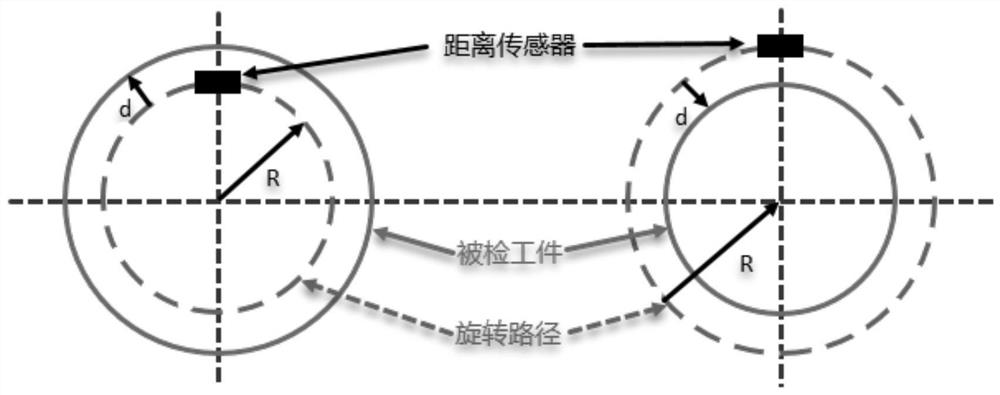

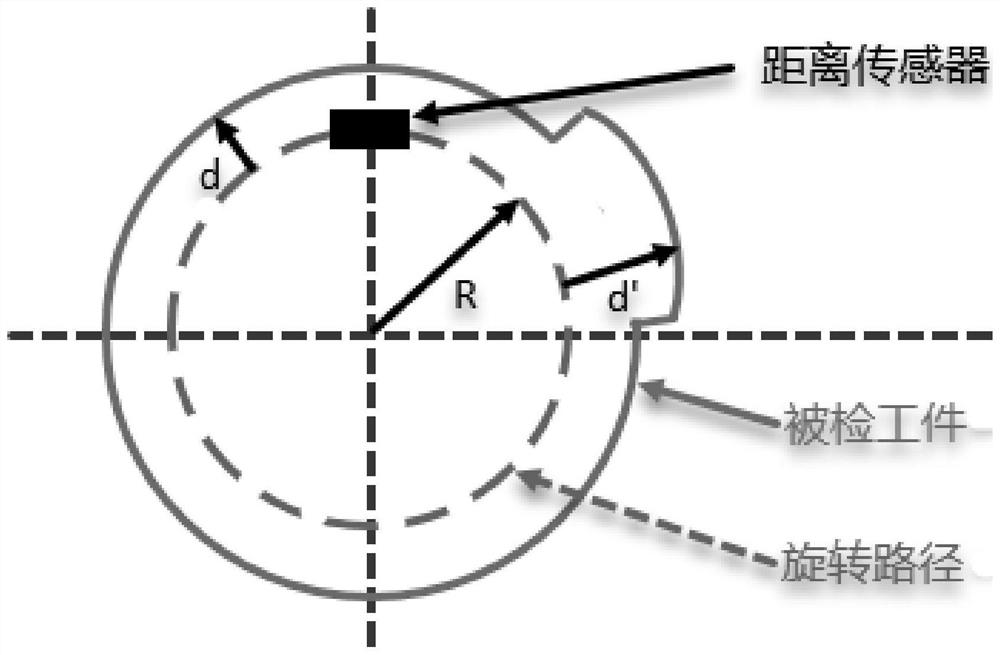

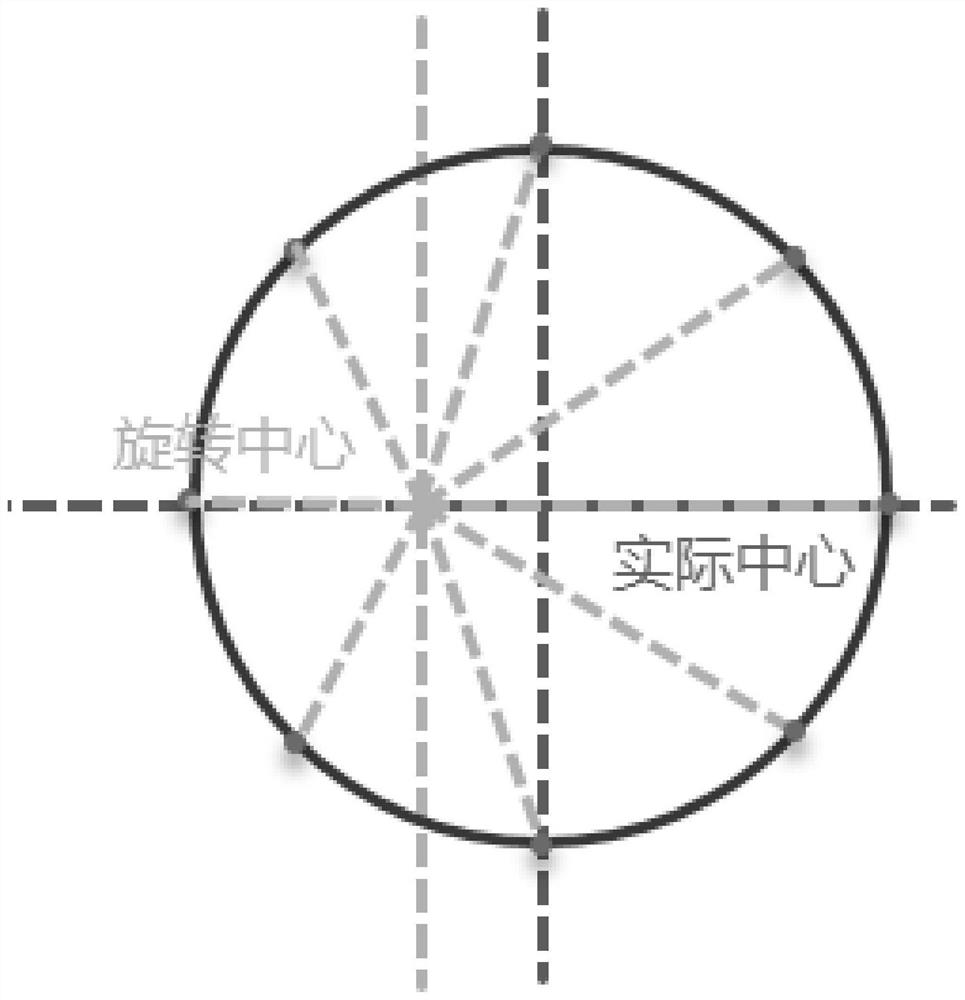

[0057] The invention is a high-precision circular contour size measurement algorithm based on non-uniform discrete data, which locates the circle center position of the inspected workpiece under the premise of not changing the measurement principle and measuring equipment, thereby calculating the high-precision circular contour size.

[0058] A high-precision circular contour size measurement algorithm based on non-uniform discrete data, which specifically includes the following steps:

[0059] Step 1: Calculate the theoretical value rat of the ratio of the circular area of the workpiece to the circumferential phase angle.

[0060] For example, the range from 0° to 270° is a circular area, then rat=0.75;

[0061] Step 2: Calibrate the rotation radius rr of the conventional measurement system

[0062] Step 2.1. Design and make a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com