Novel tension assembly structure for production of prestressed pipe pile

A prestressed pipe pile and component structure technology, applied in the direction of strengthening and forming, can solve the problems of limited stress area of screw thread, unreasonable force, poor safety, etc., and achieve simple and convenient operation of handling and loading cages, and reduce labor intensity , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

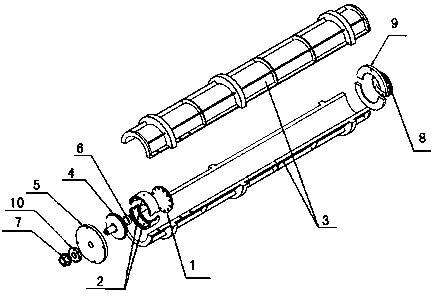

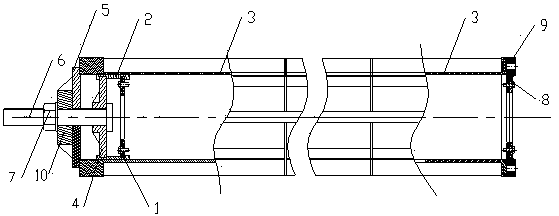

[0011] Depend on figure 1 It is known that a new type of tension assembly structure for producing prestressed pipe piles consists of a head plate 1, a clamp 2, a pipe mold 3, a tension plate 4, a baffle plate 5, a tension screw 6, a tension nut 7, and a tail plate 8 , end plate clamp 9, stretching plate 10 to form, described tensioning screw assembly is made up of tensioning plate 4, baffle plate 5, tensioning screw 6, tensioning nut 7 and stretching plate 10, tensioning screw 6 After connecting the tensioning plate 4, the baffle plate 5 and the tensioning plate 10, lock it with the tensioning nut 7; the head plate 1 is fixed on the tensioning plate 4 at one end of the tensioning screw assembly through the clamp 2, and the tensioning screw assembly at the other end The baffle plate 5 is fixed on the lower part of the pipe mold 3 by bolts, the tail plate 8 is installed on the tail plate hoop 9, and the tail plate hoop 9 is fixed on the tail end of the pipe mold 3 by bolts; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com