Transition ring connecting plastic extruder to die head

A technology of plastic extruder and transition ring, applied in the field of transition ring, can solve the problems of increasing flow channel pressure, inability to mix and reorganize materials, insufficient and accurate mixing of inner and outer layers, etc., to achieve stable material flow and improve physical Performance, uniform effect of plasticization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

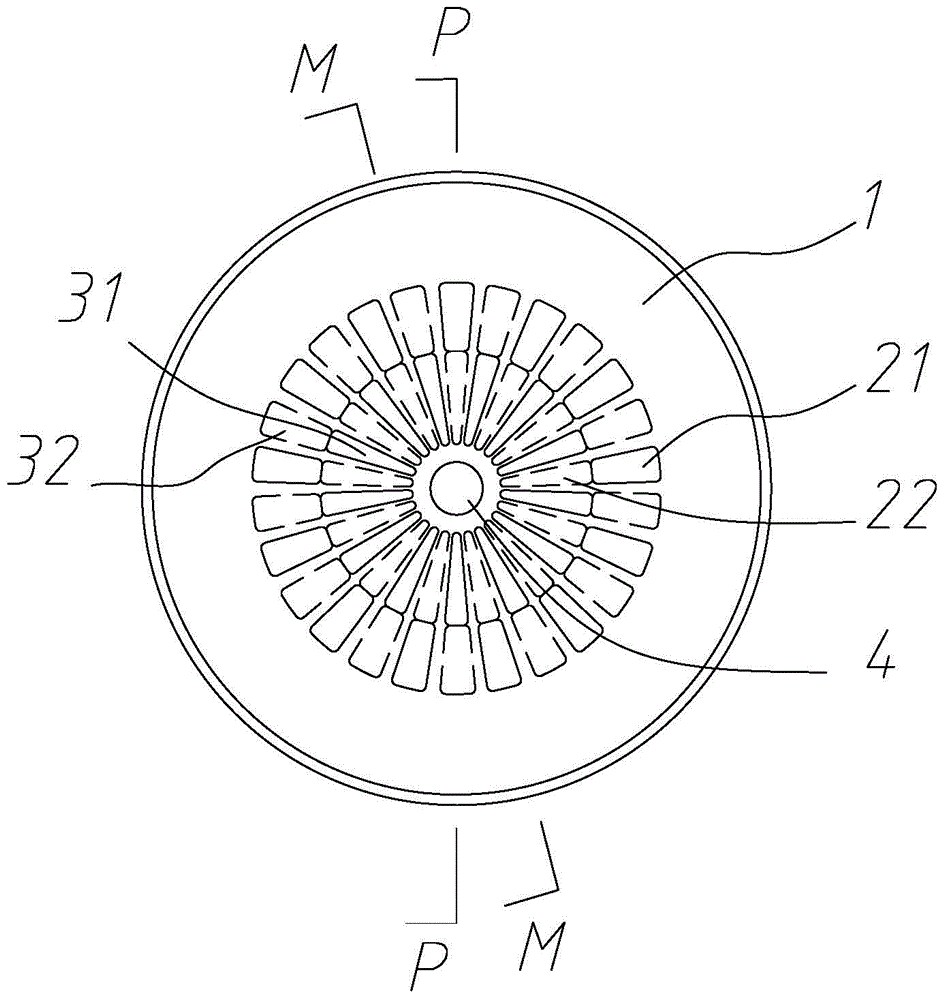

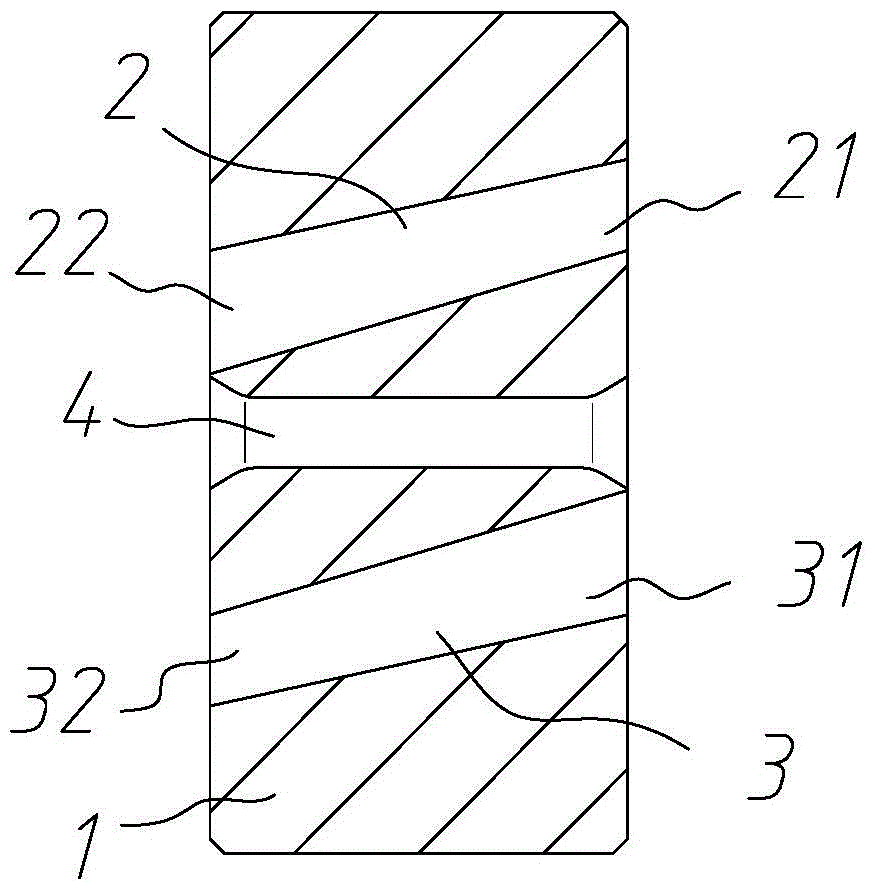

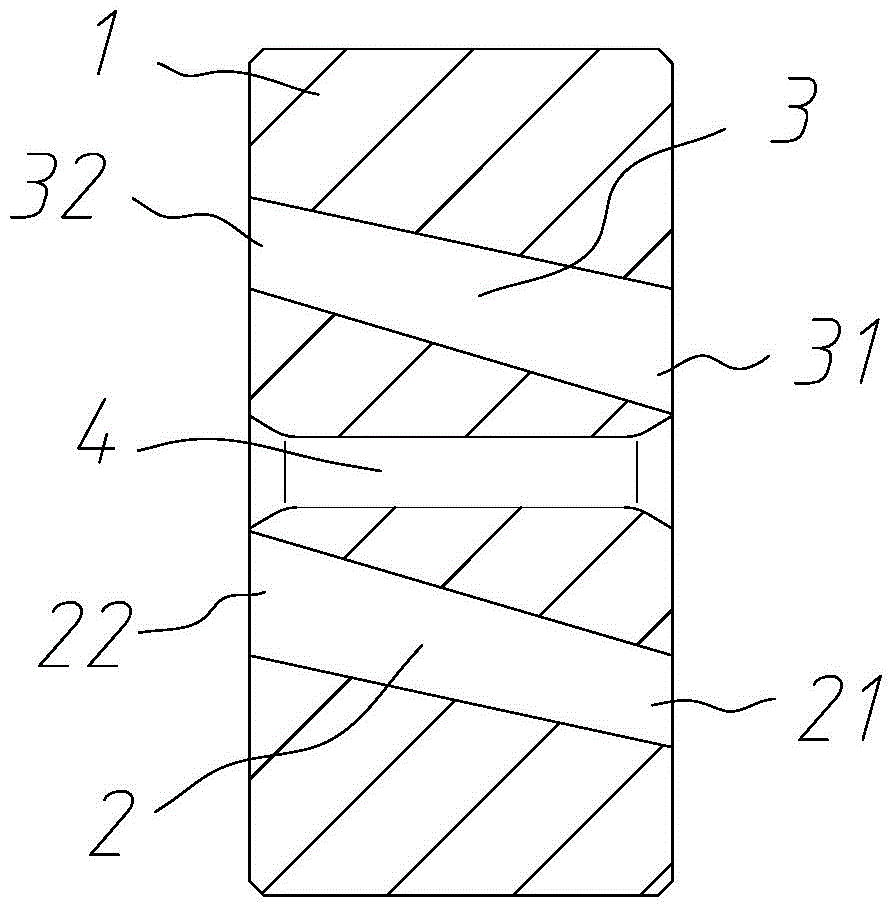

[0020] like Figure 1 to Figure 3 As shown, the transition ring 1 is a disc, in the middle of which there is an outer flow passage 3 inclined from inside to outside in the axial direction and an inner flow passage 2 inclined from outside to inside in the axial direction. The inner and outer flow passages 2, 3 are alternately distributed sequentially along the circumferential direction on the transition ring 1.

[0021] The cross-sectional shape of the inner and outer flow channels 2 and 3 is fan-shaped, and the side length of the fan-shaped section of the internal flow channel 2 gradually decreases from the inlet 21 to the outlet 22, while the arc length gradually increases, so that the cross-sectional area remains constant; Road 3 is the opposite, the side length of the fan-shaped section gradually increases from the inlet 31 to the outlet 32, and the arc length gradually decreases, so that the cross-sectional area also remains unchanged. In this example, the flow cross-sect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap