A micropowder mill analysis machine device

An analytical machine and micro-powder milling technology, which is applied in the direction of solid separation, separating solid from solid with air flow, chemical instruments and methods, etc., can solve the problems of failing to meet the fineness requirements of ultra-fine powder, complicated and bulky equipment, etc. , to achieve reasonable design, improve powder selection efficiency and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

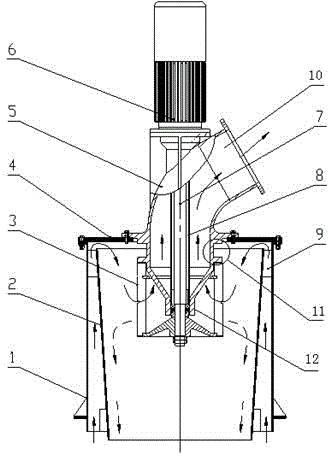

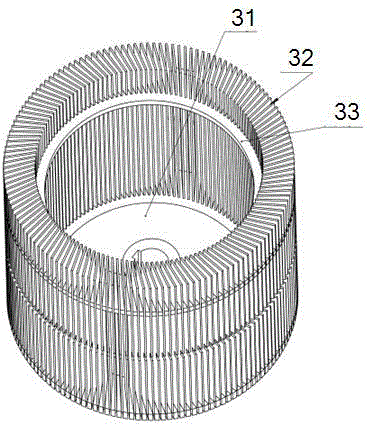

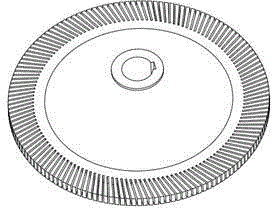

[0023] see figure 1 , it is a kind of micropowder mill analysis machine device of the present invention. As shown in the figure: it includes the upper casing of the pulverizer 1, the air flow isolation ring 2, the squirrel cage blade rotor 3, the upper body seat plate of the powder classifier 4, the upper body of the powder classifier 5, the frequency conversion motor 6, the transmission shaft 7, and the transmission bearing Barrel 8, support plate set 9 and air flow channel 10. Wherein: the transmission bearing cylinder 8 is located in the center of the upper body 5 of the powder separator, and the transmission shaft 7 is installed inside the transmission bearing cylinder 8; the upper part of the transmission shaft 7 is equipped with a frequency conversion motor 6, and the lower part is equipped with a squirrel-cage blade rotor 3; The upper machine body 5 is fixed on the center of the upper body seat plate 4 of the powder classifier, the upper body seat plate 4 of the powder...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap