A method for automatic control of ore unloading of large ring cooler

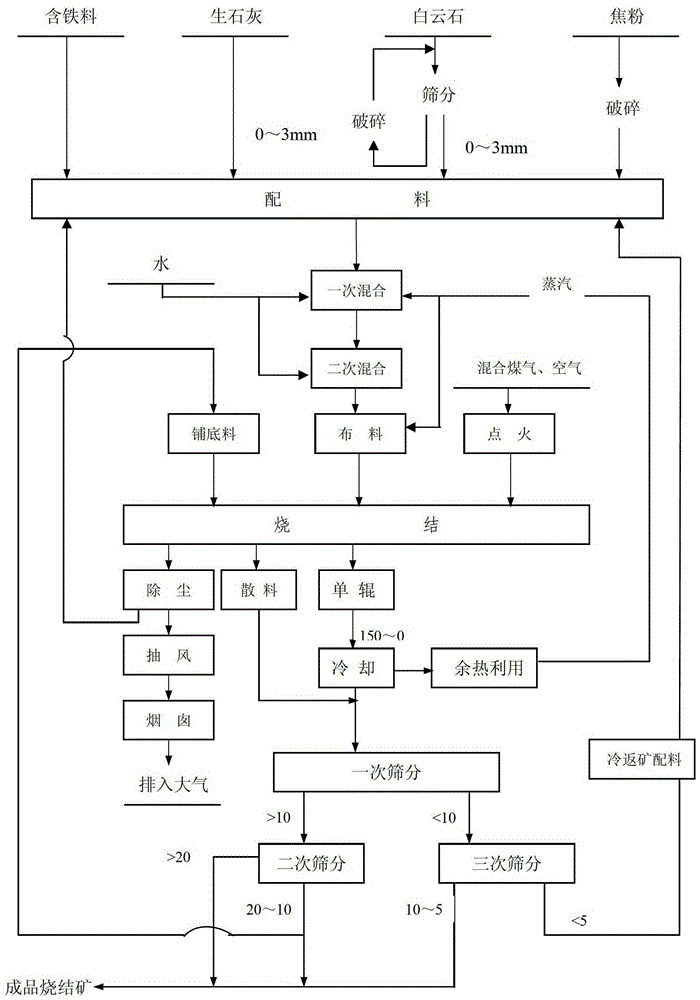

A ring cooler, large-scale technology, applied in the program control and electrical program control in the sequence/logic controller, etc., can solve the problem of increased wear and tear of the discharge trough of the ring cooler, uneven output of the plate feeder, and unloading. The problem of low material level control in the trough can achieve the effect of good effect, reduced curve fluctuation and stable material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

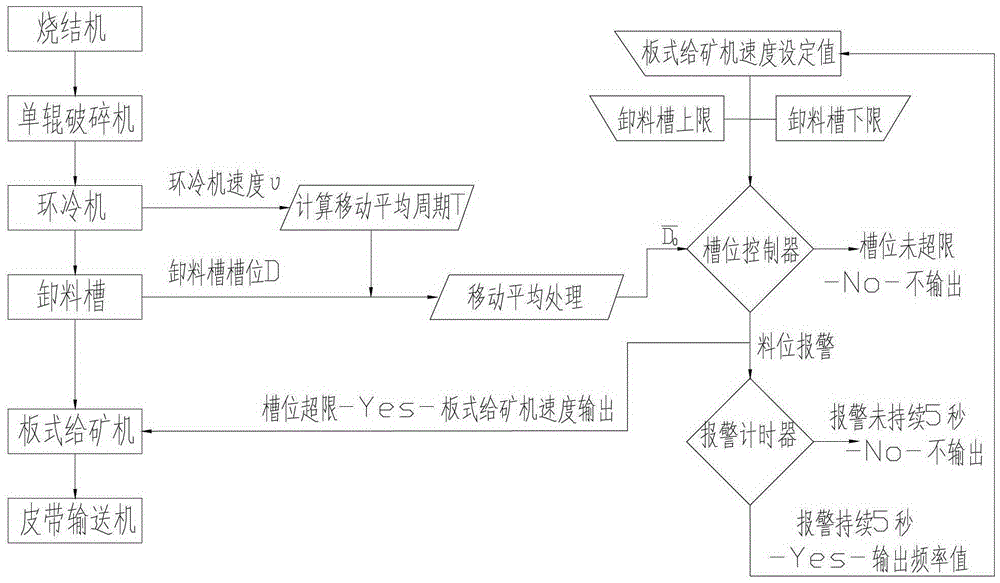

[0034] Use the real-time signal processing program of the unloading ore tank material level and the discharge ore tank material level controller program in PLC programming;

[0035] 1) PLC conditions:

[0036] ① Feedback value D of the signal feedback value of the weighing sensor of the discharge tank of the ring cooler;

[0037] ②The feedback value V of the motor frequency signal of the ring cooler;

[0038] ③Frequency feedback value of plate feeder motor;

[0039] 2) PLC programming:

[0040] ① The real-time signal of the material level of the unloading ore tank is used for the moving average calculation process;

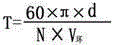

[0041] Moving average period T

[0042] T = 60 × π × d N × V

[0043] In the above formula: d——the diameter of the motion track of the C ring cooler, m;

[0044] N——The tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com