A continuous labeling device and its labeling process

A technology of cutting device and conveying device, which is applied in the direction of labeling, labeling machine, labeling, etc., and can solve the problems of low production efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

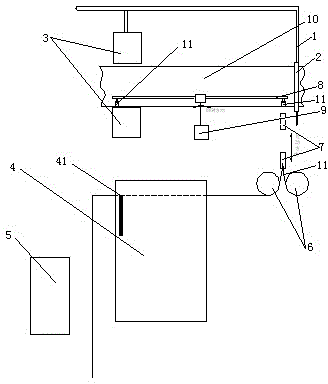

[0017] A continuous labeling device of the present invention includes a frame 1, a number of fabric guide rollers 2 arranged on the frame, an edge winch 3 arranged in the working area, and an automatic labeling device arranged at the edge of the edge.

[0018] The cloth 10 passes through the working area on the frame 1 horizontally, and the two sides of the cloth 10 perpendicular to the advancing direction of the cloth are provided with a winch 3 fixedly connected to the frame 1, and the two sides of the cloth are connected by the winch 3. The sides are hemmed. In order to realize automatic and continuous labeling, the labeling and hemming processes are combined into one process to realize efficient production in turn. The specific improvement structure is as follows: the automatic labeling device is set on the frame 1 and the hemming machine 3 on one side of the cloth position, the above-mentioned automatic labeling device sequentially includes a label strip fixed-length cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com