Application of styrene-based elastomer as an additive to improve low-temperature folding resistance of polypropylene and its preparation of folding-resistant polypropylene

A styrene and elastomer technology, applied in the field of polymer material molding and processing, can solve the problems of poor low-temperature folding resistance, loss of transparency and folding resistance, and achieve the effects of excellent transparency and excellent low-temperature folding resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 94.6 kg of polypropylene PP RP346R, 5 kg of styrene-based elastomer SEPTON 2002, 0.2 kg of heat stabilizer 1010, and 0.2 kg of heat stabilizer 168 were melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature of each section of the extruder is set at 220~260°C, extruded and granulated, and finally the product is obtained.

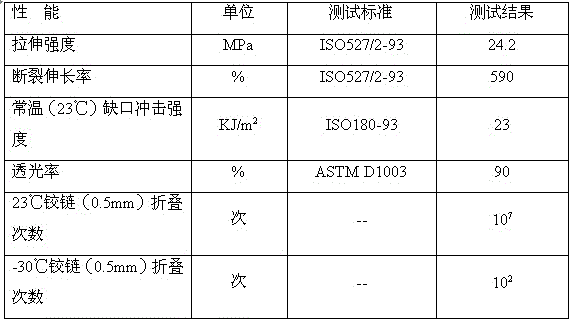

[0057] Test its performance according to the corresponding standards, the list is as follows:

[0058]

Embodiment 2

[0060]69.4 kg of polypropylene PP RP346R, 20 kg of polypropylene PP S700, 10 kg of styrene-based elastomer SEPTON 2063, 0.3 kg of heat stabilizer 1010, and 0.3 kg of heat stabilizer 168 were extruded in a twin-screw extruder with an aspect ratio of 40:1 Melt, mix and disperse in the extruder, set the temperature of each section of the extruder at 220~260°C, extrude and granulate, and finally get the product.

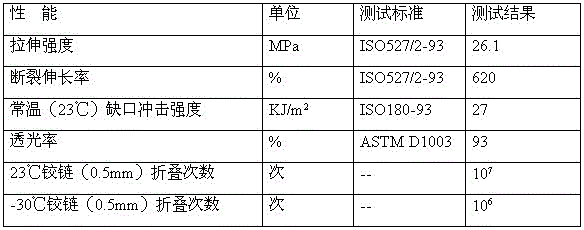

[0061] Test its performance according to the corresponding standards, the list is as follows:

[0062]

Embodiment 3

[0064] Extrude 54.1 kg of polypropylene PP SM256, 30 kg of polypropylene PP T30S, 15 kg of styrenic elastomer SEBS6006, 0.5 kg of heat stabilizer 1010, and 0.4 kg of heat stabilizer 168 in a twin-screw with an aspect ratio of 40:1 Melt, mix and disperse in the machine, set the temperature of each section of the extruder at 220~260°C, extrude and granulate, and finally get the product.

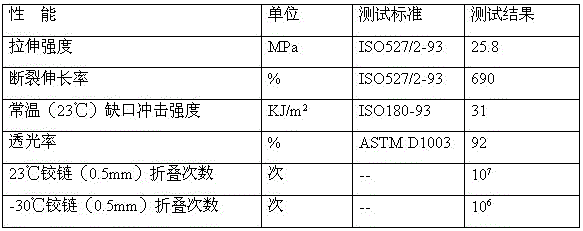

[0065] Test its performance according to the corresponding standards, the list is as follows:

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com