A decorative thermal insulation composite wall and its manufacturing method

A thermal insulation composite, wall technology, applied in thermal insulation, walls, building components and other directions, can solve the problems of the insulation layer cavity is not compact, the impact of foam concrete pouring, etc., to shorten the building installation period, improve the building seismic performance, reduce the consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

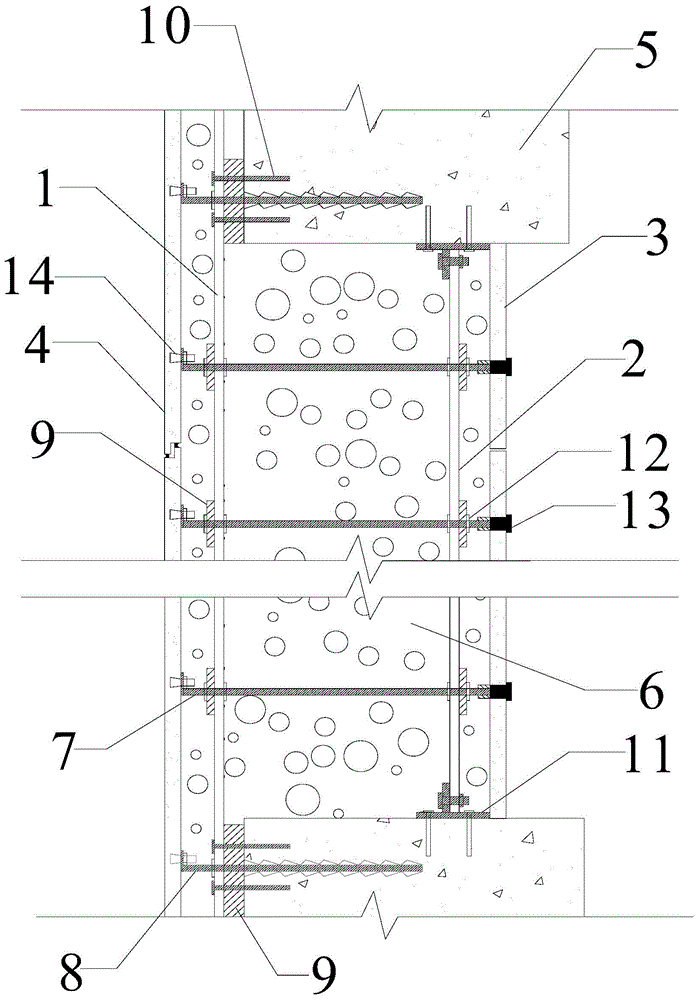

[0037] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0038] Such as figure 1 As shown, a method for manufacturing a decorative and thermal insulation composite wall, comprising the following steps:

[0039] Fix the first metal keel 1 and the first inorganic plate 3 opposite to the first metal keel 1 on the main structure 5;

[0040] A plurality of screws are sequentially passed through and fixed to the first metal keel 1 and the first inorganic plate 3, wherein the screws located at the main structure 5 are passed through and fixed to the first metal keel and the main structure 5 in sequence;

[0041] The exterior wall decoration board 4 is installed, and the exterior wall decoration board 4 is fixed on the outside of the first metal keel 1 by the dry hanging piece 14;

[0042] The thermal insulation slurry is injected into the space between the exterior wall decor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com