Decoration heat-insulating composite wall body and preparation method thereof

A thermal insulation composite and wall technology, which is applied in thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of adverse effects on the curing performance of adhesives, reduce the physical and mechanical properties of materials, and affect the secondary processing performance. Durability, improved system safety and strength, and improved seismic performance of buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

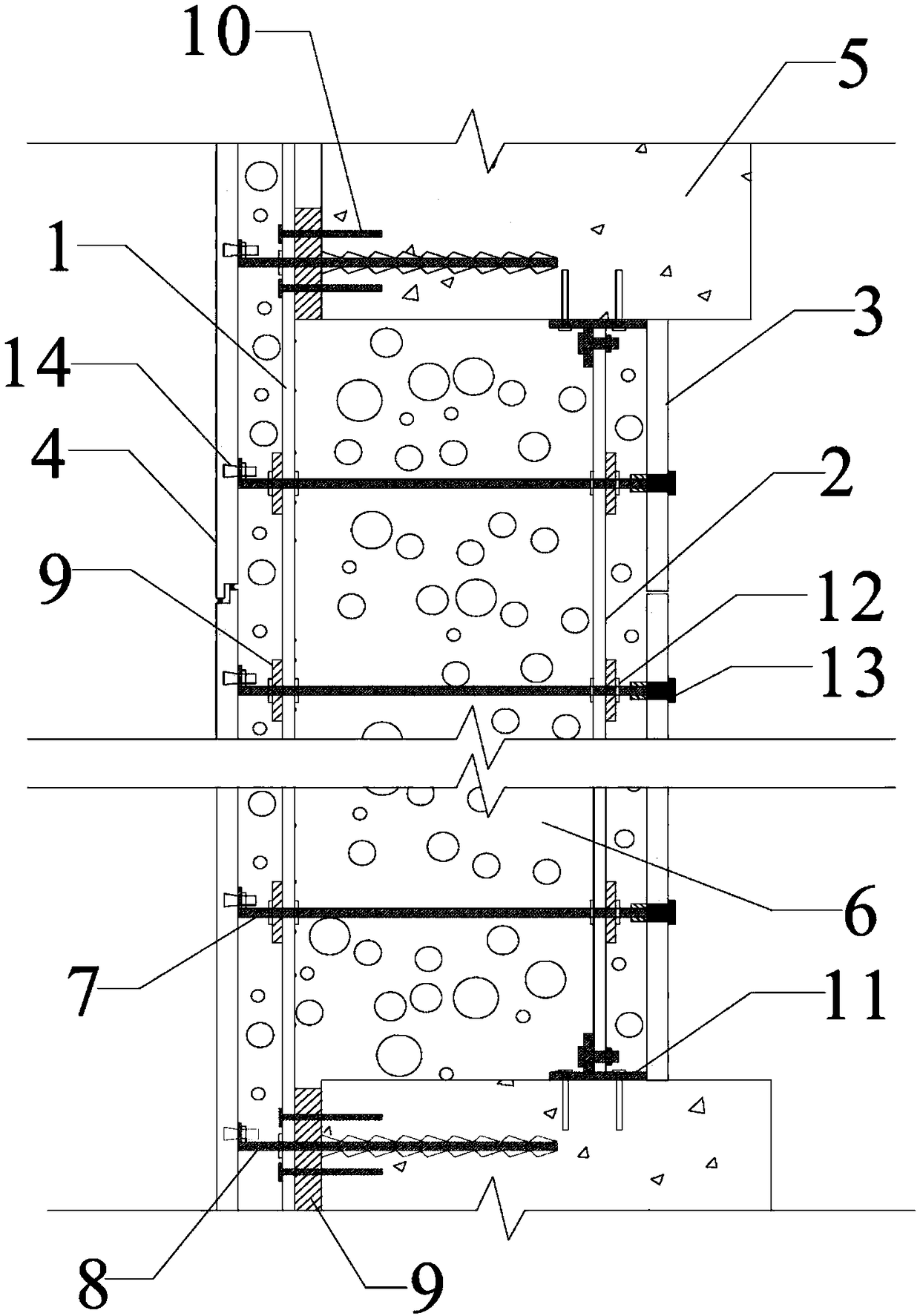

[0017] A decorative and thermal insulation composite wall of the present invention is characterized in that it includes a first screw rod, a second screw rod, a first metal keel fixedly connected with the main structure, and a first inorganic board; the first inorganic board and the first The metal keels are arranged opposite to each other, and a grouting hole is provided on the first inorganic plate; the first screw passes through the first metal keel and the first inorganic plate in turn, and the second screw passes through the first The metal keel and the main structure; the side of the first metal keel away from the first inorganic board is provided with an exterior wall decoration board, and an insulation layer is provided between the exterior wall decoration board and the first inorganic board The exterior wall decoration board is connected with a dry hanging piece, and the dry hanging piece is fixedly connected with the first screw and the second screw or the first metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com