Underground Coal Gasification Method

An underground gasification and coal technology, which is applied in coal gasification, underground mining, construction, etc., can solve the problems of long time to reach production capacity of gasifier, lower gasification efficiency, and ineffective use of water vapor, etc., so as to shorten the time to reach production capacity time, improve stability, and basically stabilize the gas injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

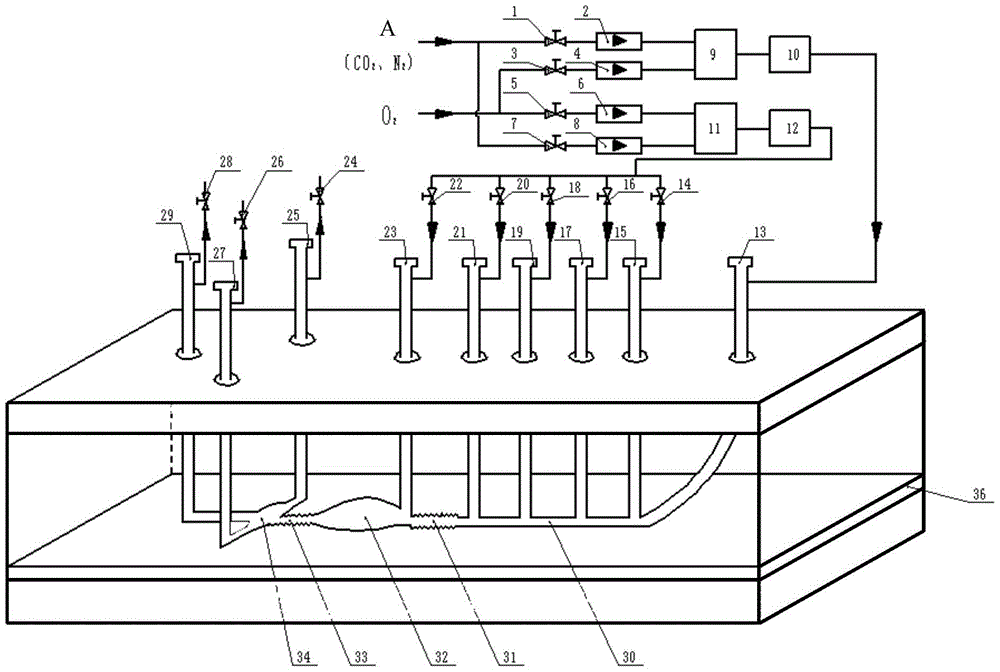

[0019] Now, the method of continuous underground gasification of coal in forward and reverse directions is described in detail, that is, the method of continuous gasification of underground coal while conducting firepower penetration.

[0020] Specifically, the method includes the following steps. In step 1, a directional horizontal channel is constructed in the coal seam, and an ignition hole, at least two auxiliary holes, and a first directional hole are sequentially arranged along the directional horizontal channel. The directional horizontal channel is sequentially connected with the ignition hole, the auxiliary hole and the first directional hole in its extension direction, thereby dividing the directional horizontal channel into a continuous channel segment combination. That is, in the extension direction of the directional horizontal channel, the ignition hole, the auxiliary hole and the first directional hole are arranged one after another, and these holes are all connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com