Gun sight

A sight and lens barrel technology, applied in the field of scope, can solve the problems of low aiming accuracy and inability to guarantee shooting accuracy, and achieve the effects of improving aiming accuracy, improving comfort, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

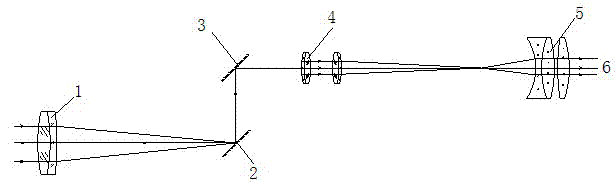

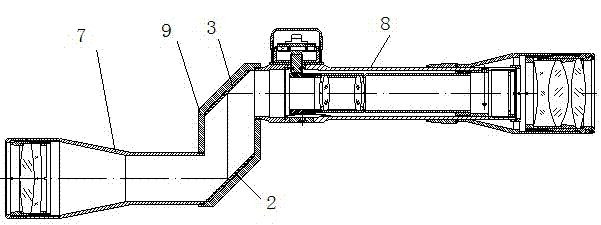

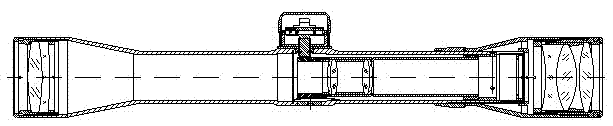

[0012] Below in conjunction with accompanying drawing, the present invention is described in detail: as figure 1 , figure 2 Shown, the scope of the present invention, eyepiece barrel comprises objective lens fixed lens barrel 7, eyepiece fixed lens barrel 8 and connecting lens barrel 9, connecting lens barrel 9 connects objective lens fixed lens barrel 7 and eyepiece fixed lens barrel 8, objective lens fixed lens barrel 7 It is parallel to and not on the same axis with the eyepiece fixed lens barrel 8, and the two form a Z-shape with the connecting lens barrel 9. The objective lens 1 is installed at the end of the objective lens fixed lens barrel 7, the eyepiece 5 is installed at the end of the eyepiece fixed lens barrel 8, and the turning mirror 4 is installed inside the eyepiece fixed lens barrel 8. Two parallel and opposite first reflecting mirrors 2 and second reflecting mirrors 3 are installed in the connecting lens barrel 9, the first reflecting mirror 2 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com