Resin matrix composite circular tube sealing experimental device

A technology of composite materials and experimental devices, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve good elongation, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

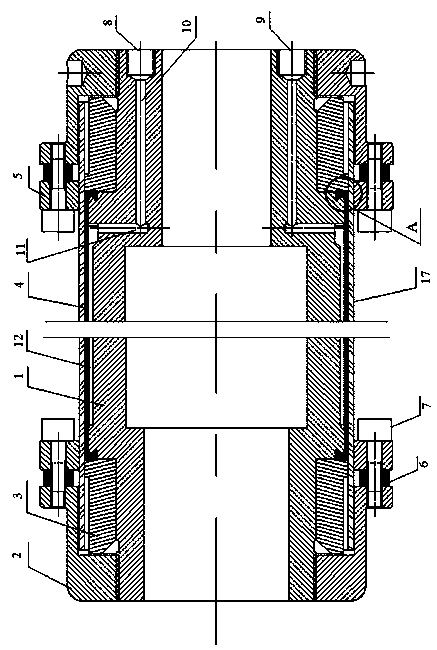

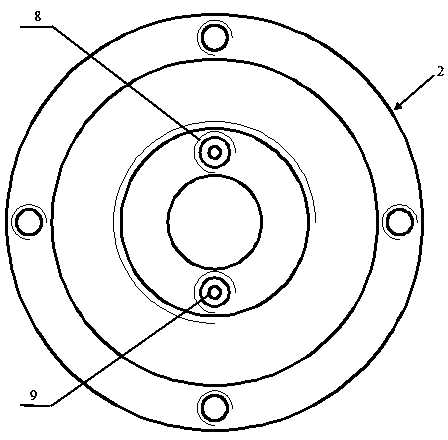

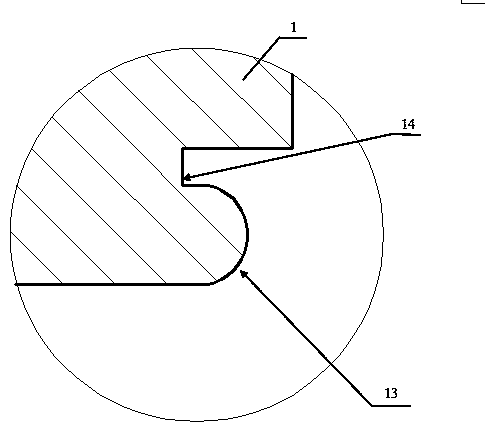

[0024] Hereinafter, with reference to the accompanying drawings and examples, the resin-based composite material circular tube sealing experimental device of the present invention is described in detail:

[0025] Such as Figure 1~4 As shown, the resin-based composite material circular pipe sealing experiment device includes a support cylinder 1, and nuts 2 are respectively threaded at both ends of the support cylinder 1, and a pressure ring 3 is arranged inside the nut 2. A cylindrical rubber lining 4 is arranged between the outer circle of the middle part of the cylinder body 1 and the two pressure rings 3, and a round tube 17 to be tested is placed on the outer circle of the rubber inner liner 4. 17 Two ends of the outer circle are respectively provided with hoops 5, and a washer 6 is arranged between the nut 2 and the hoop 5, and the nut 2, the hoop 5 and the washer 6 are connected together by bolts 7.

[0026] The inner diameter of the support cylinder 1 is a stepped hol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap