Withstand voltage test mechanism

A technology of withstand voltage test and withstand voltage tester, which is applied in the direction of testing dielectric strength, etc., can solve the problems that affect the accuracy of test results, easily scratch the surface of electrical products, damage electrical products, etc., and achieve good protection performance and rapid action , full exposure to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] It should be noted that this embodiment is preferably applied to the production and manufacture of LED lamps.

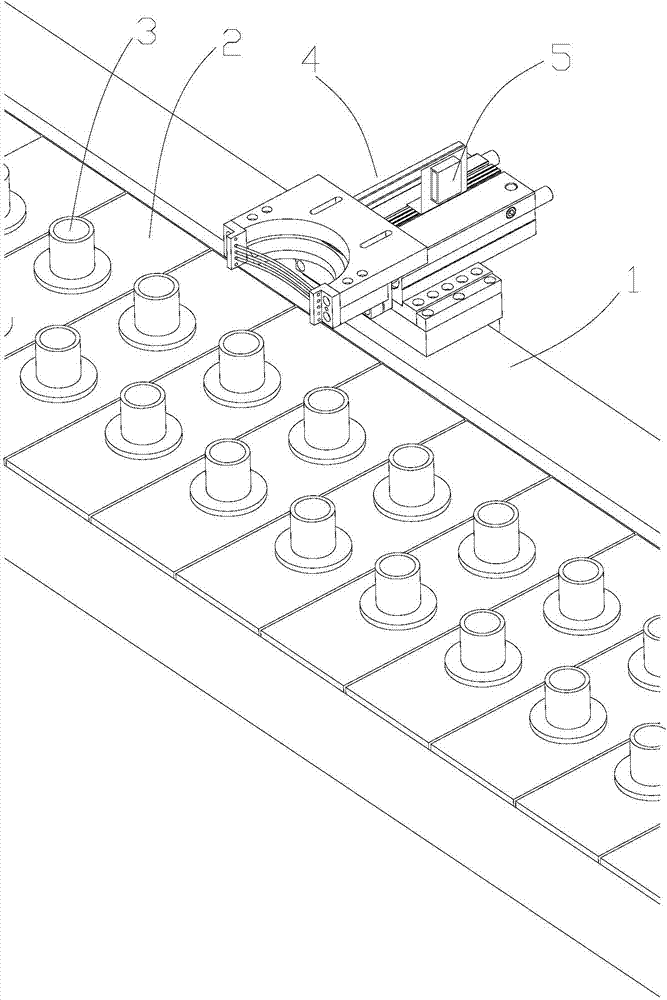

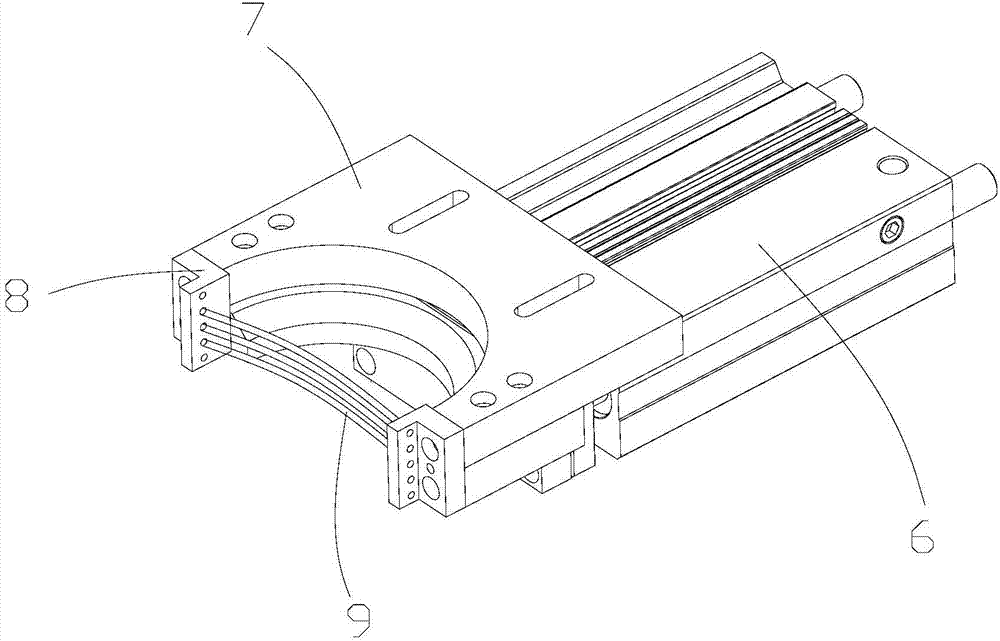

[0023] see figure 1 , a withstand voltage testing mechanism, including a withstand voltage tester (not shown), and also includes: a bracket 1, a transmission line 2, a power seat 3, an activity detection mechanism 4 and a photoelectric switch 5;

[0024] Bracket 1 is used to provide support for the entire device.

[0025] The transmission line 2 is used to transport the electrical products one by one to the activity detection mechanism 4 for withstand voltage testing; the transmission line 2 is installed on the bracket 1 . A brush (not shown) is installed inside the conveying line 2 .

[0026] The electrification seat 3 is used for installing electrical products and carrying out a withstand voltage test on the electrical products connected to high-voltage electricity; the electrification seat 3 is installed on the transmission line 2 . The electrification s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com