A cathode structure of a proton exchange membrane fuel cell

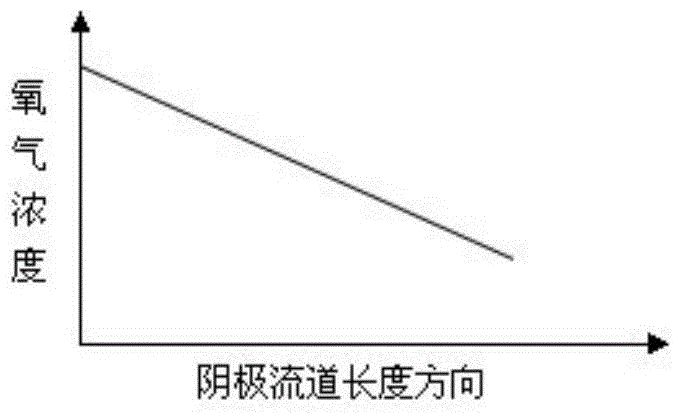

A proton exchange membrane and fuel cell technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of oxygen concentration reduction, failure to reach, hinder oxygen diffusion, etc., achieve uniform distribution of oxygen concentration, improve distribution state, increase The effect of work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

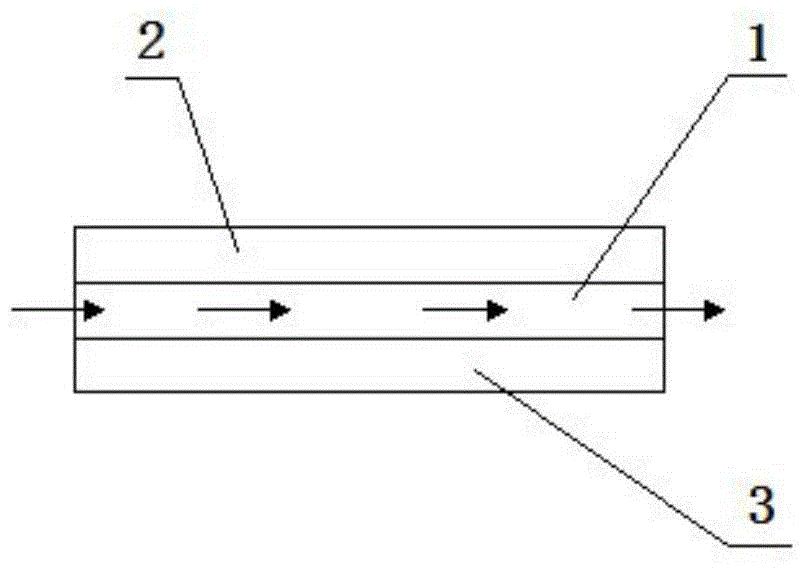

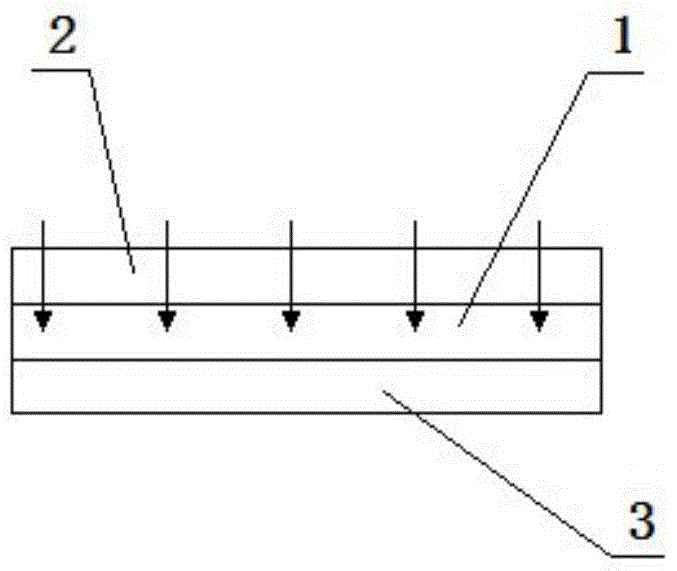

[0032] Figure 5 , Figure 6 The structure of a flow field plate in the embodiment of the present invention is illustrated respectively in the form of a front view and a top view.

[0033] see Figure 5 , the flow field plate 2 in this embodiment is arranged as a symmetrical structure between the A surface and the B surface, the B surface directly contacts the membrane electrode 3 and there are several flow channels 1 evenly spaced thereon, the A The surface is symmetrical to the B surface, and the grooves 22 corresponding to the position of the flow channel 1 are arranged evenly on it, and the flow channel 1 and the groove 22 are connected through several round holes 23; see Figure 6 A plurality of the circular holes 23 are arranged in order of diameter on the flow channel 1 and the groove 22 connected therewith.

[0034] In this embodiment, the cathode air enters the groove 22 of the flow field plate 2 on the A side through the air inlet, then passes through the circular...

Embodiment 2

[0037] Figure 7 The structure of another flow field plate in the embodiment of the present invention is illustrated.

[0038] see Figure 7 , the cross-sectional structure of the flow field plate 2 in this embodiment is a trapezoidal tooth shape, and the flow field plate 2 is also provided with two sides A and B, but the B side directly contacts the membrane electrode 3 and is concave toward A The trapezoidal tooth shape of the surface forms the flow channel 1, and the trapezoidal tooth shape of the A surface forms a groove 22 with its concave to the B surface. The flow channel 1 is adjacent to the grooves 22 on both sides, and passes through several The circular holes 23 are connected; several circular holes 23 are arranged on the flow channel 1 and the groove 22 connected therewith in the order of gradually increasing diameter along the direction of cathode air delivery.

[0039]In this embodiment, the cathode air enters the groove 22 of the flow field plate 2 on the A si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com