Easy-to-use nail puller

A nail puller, a convenient technology, applied in the directions of hand tools, hand tools, manufacturing tools, etc. suitable for fasteners, can solve the problems of large rivet holes in the cabinet, easy damage to the nail puller, etc., and achieves protection. , easy to disassemble, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

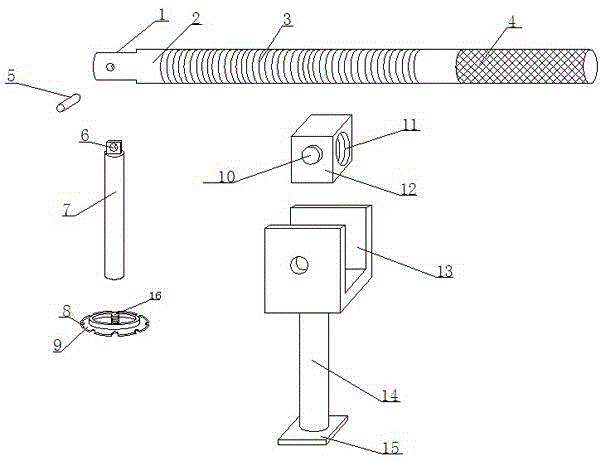

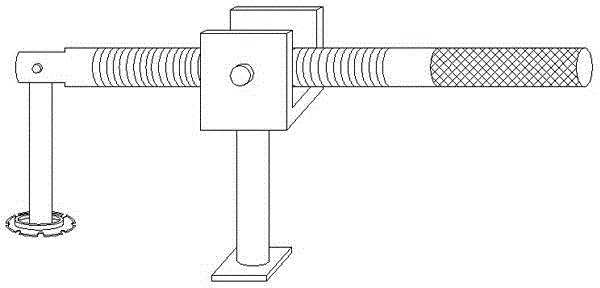

[0018] Such as Figure 1-Figure 3 The illustrated nail puller includes a U-shaped frame 13, a support bar 14 is connected to the lower end of the U-shaped frame 13, a backing plate 15 is connected to the lower end of the support bar 14, and a rotating block is arranged inside the U-shaped frame 13. 12. Both sides of the rotating block 12 are provided with a rotating shaft 10 connected to the U-shaped frame 13. The rotating block 12 can rotate in the U-shaped frame 13 with the rotating shaft 10 as the axis. The rotating block 12 is provided with a threaded passage Hole 11, the threaded through hole 11 is provided with a pressure rod 2, the middle part of the pressure rod 2 is provided with an external thread 3 cooperating with the threaded through hole 11, the left end of the pressure rod 2 is provided with a mounting groove 1, and the mounting groove 1 is positioned by The pin 5 is connected with a connecting rod 7, the upper end of the connecting rod 7 is provided with a conn...

Embodiment 2

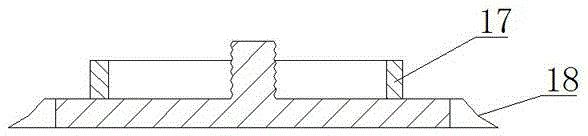

[0022] In this embodiment, the following structure is added on the basis of Embodiment 1: an annular weak magnet 17 is bonded to the upper end surface of the nail pulling disc 9 .

[0023] In this embodiment, the ring-shaped weak magnet 17 is bonded to the upper end surface of the nail pulling disc 9, which not only can absorb the rivet taken out, but also prevent it from falling into the gap or narrow place inside the cabinet, which is inconvenient to find and cannot be reused. Due to excessive force when pulling out the nail, the rivet will directly shoot out, which can easily cause damage to the workers around. Therefore, in order to protect the worker and facilitate the collection of the rivet, a weak magnet 17 is added on the nail pulling plate 9.

Embodiment 3

[0025] This embodiment is optimized as follows on the basis of embodiment 1 or embodiment 2: the thickness of the nail-pulling disk 9 is 1-2.5 millimeters, and the upper end surface of the nail-pulling disk 9 is smaller than the lower end surface of the nail-pulling disk 9 , and the circumferential surface of the nail pulling disc 9 is an arcuate surface 18.

[0026] In this embodiment, in order to quickly cut into the bonding surface between the rivet and the cabinet body for the nail pulling disc 9, its thickness is generally not greater than 2.5 mm. The circumferential surface of 9 is set to arc surface 18, facilitates pulling out nail dish 9 and cuts in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com