Large-size frame type roll-over machine

A turning machine and frame-type technology, which is applied in the direction of molding machines, casting molding equipment, metal processing equipment, etc., can solve the problem that the sand mold cannot be hoisted, hung, turned over, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings.

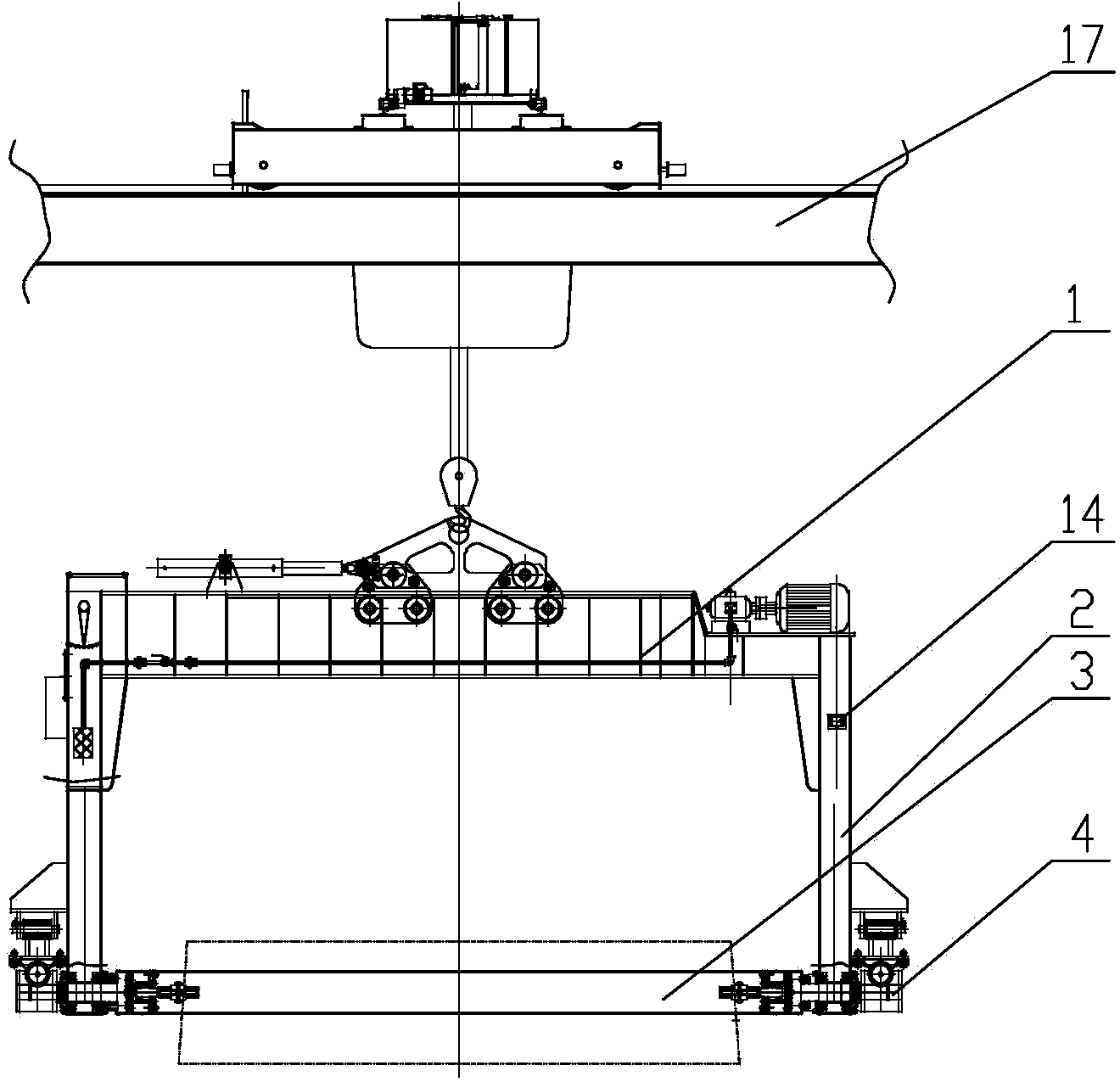

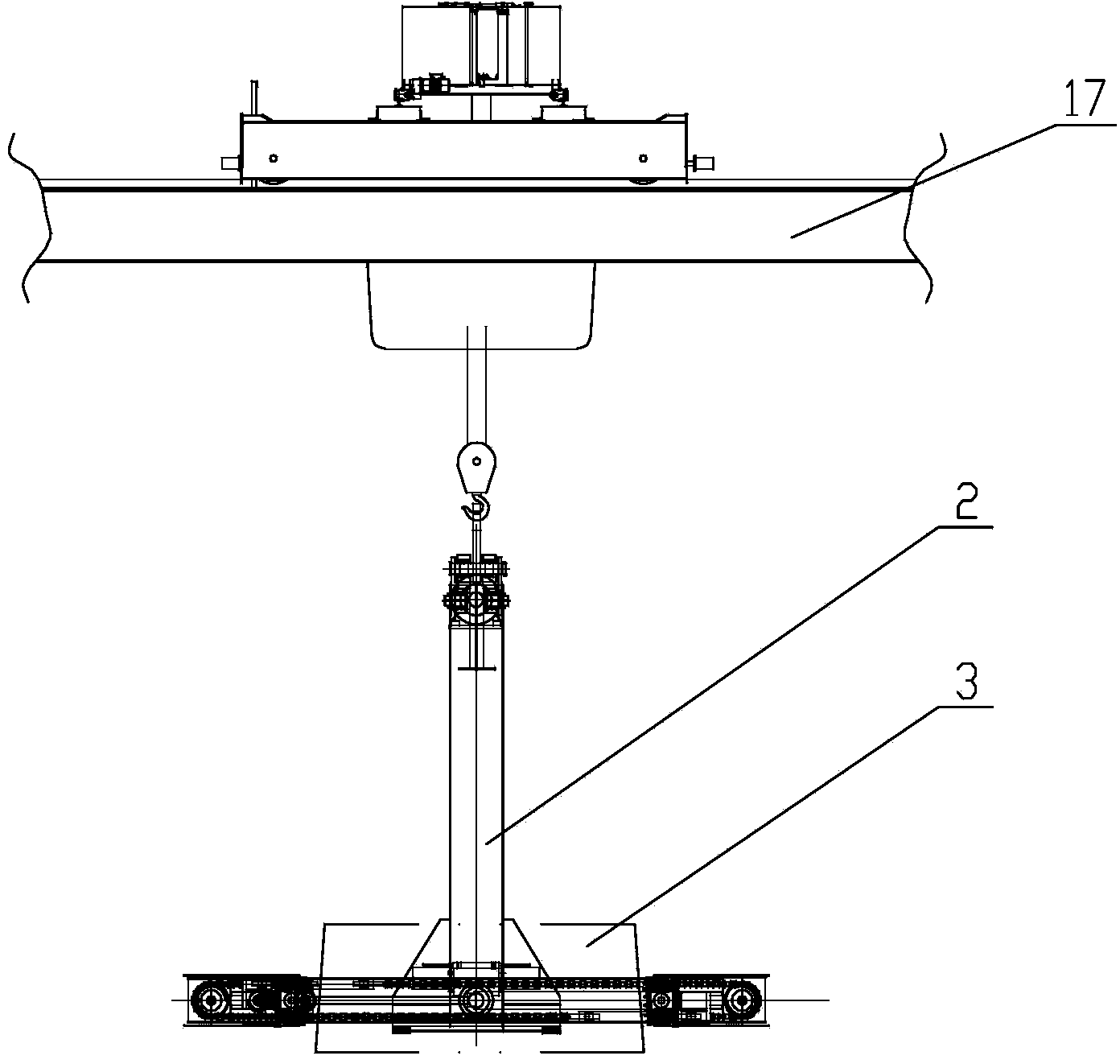

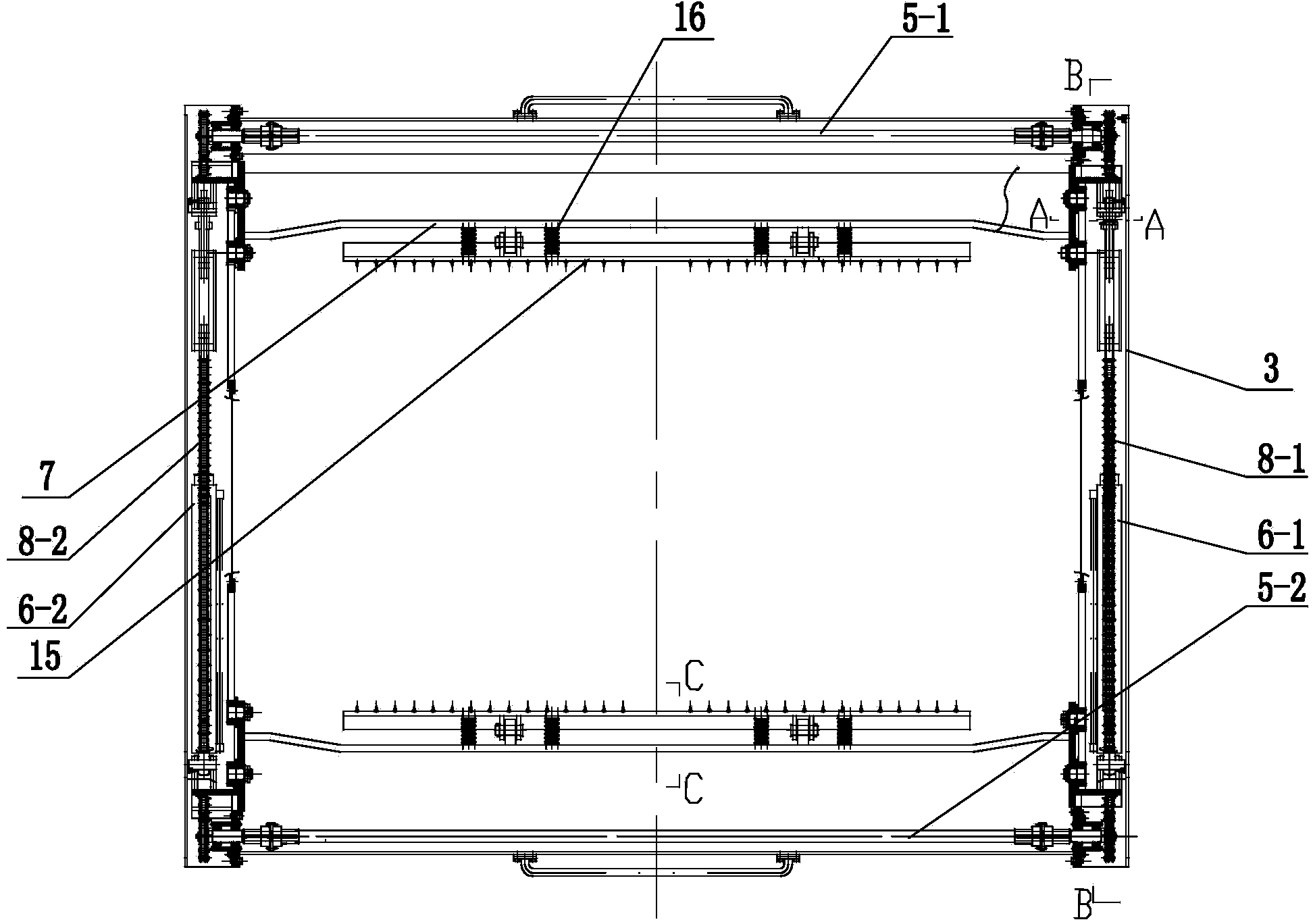

[0018] Such as Figure 1 to Figure 8 As shown: the large frame type turning machine includes an upper beam 1, a boom 2, a turning frame 3, a rack cylinder 4, a first synchronous shaft 5-1, a second synchronous shaft 5-2, and a first clamping cylinder 6-1, the second clamping oil cylinder 6-2, the splint 7, the first synchronous chain 8-1, the second synchronous chain 8-2, the I-shaped rail 9, the lug plate 10, the upper guide wheel group 11, the lower guide Wheel set 12, center of gravity adjustment oil cylinder 13, inclination sensor 14, nail plate 15, spring 16, etc.

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a gantry hanger and an overturning frame 3 arranged below the gantry hanger, the overturning frame 3 is a frame structure assembled from rectangular steel; the gantry hanger includes an upper beam 1 and a boom 2, and the upper beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com