Special hanging rack for wrench

A hanger and wrench technology, which is applied in the field of hangers and hangers for hanging wrenches, can solve the problems of reducing the convenience of use and work efficiency, consuming a long time, and confusing storage methods, so as to achieve simple structure and save time , Take quick and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

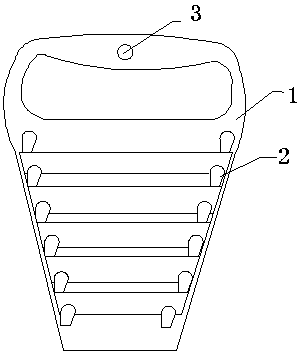

[0015] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0016] Such as figure 1 Shown: the special hanger for wrench, including the hanger body 1, the hanger body 1 is provided with multiple sets of hooks 2 from top to bottom, each set of hooks 2 is two, symmetrically arranged on the left and right sides of the hanger body 1 end, and the top of the hanger body 1 is also provided with a hanging hole 3 .

[0017] In this embodiment, the distance between each set of hooks 2 gradually decreases from top to bottom, so as to accommodate the placement of wrenches with different lengths.

[0018] Moreover, the hanging hole 3 is a pin insertion hole, which is very convenient for quick storage of the hanger body 1 .

[0019] And the material of the hanger body 1 is plastic, the production cost is low, econo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com