Method for designing front longitudinal girder

A design method, the technology of the front longitudinal beam, applied to the substructure, transportation and packaging, vehicle parts, etc., can solve the problems of low efficiency and high cost, and achieve the effect of reducing development costs, less possibility and fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0034] The design method of the front load-bearing part of the vehicle body disclosed by the present invention comprises:

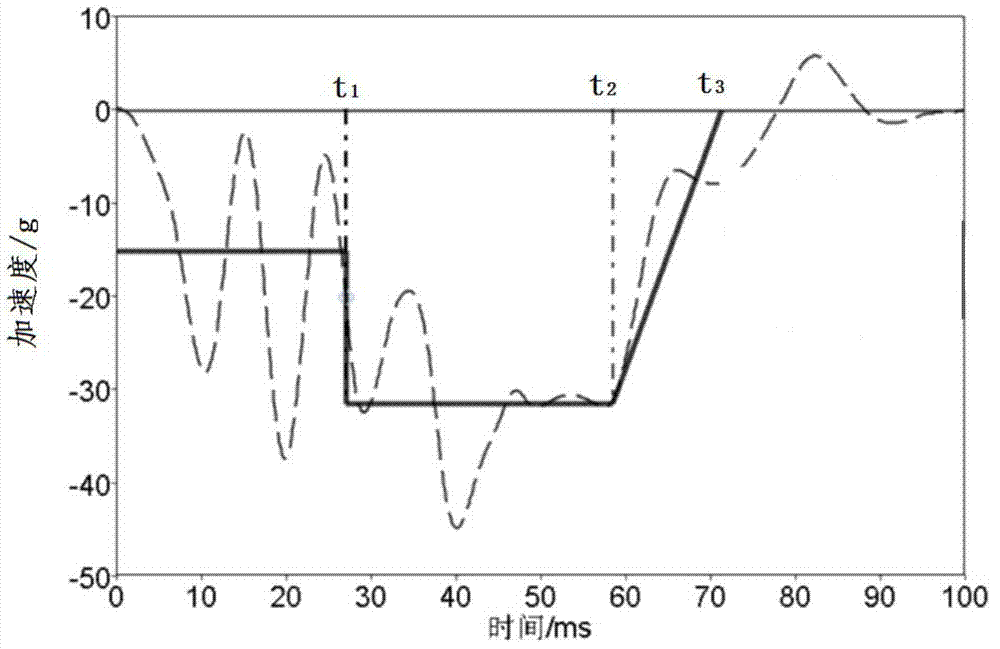

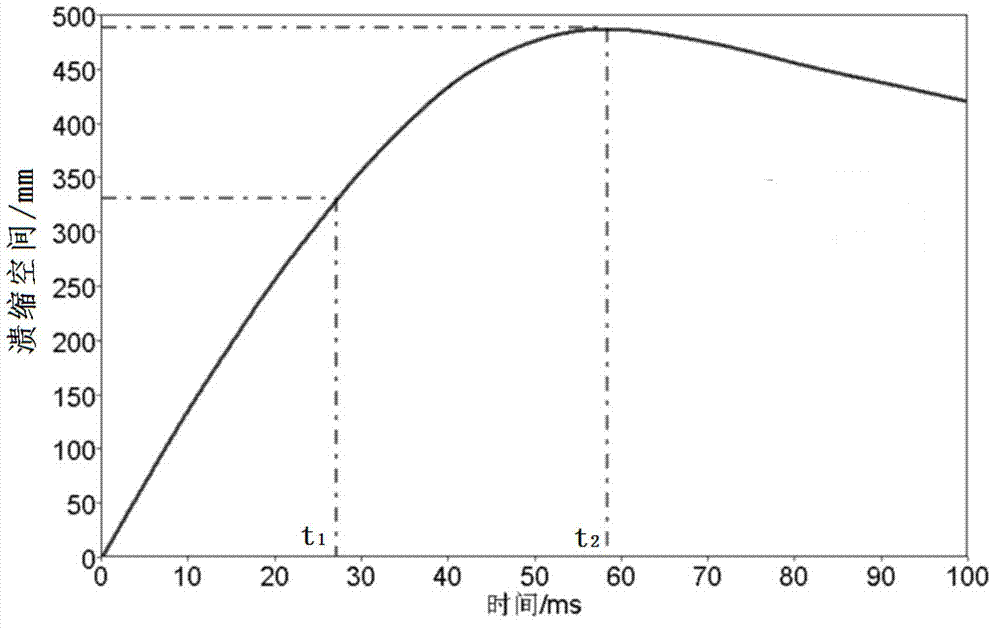

[0035] S1. Obtain the acceleration-time curve and the crushing distance-time curve of the benchmark vehicle during a frontal collision;

[0036] S2. The length from the front end of the front side beam of the target vehicle to the front end of the powertrain is X; combine the crushing distance-time curve to obtain the first moment t when the crushing starts 0 , and the corresponding second moment t when the crushing distance is X 1 ;

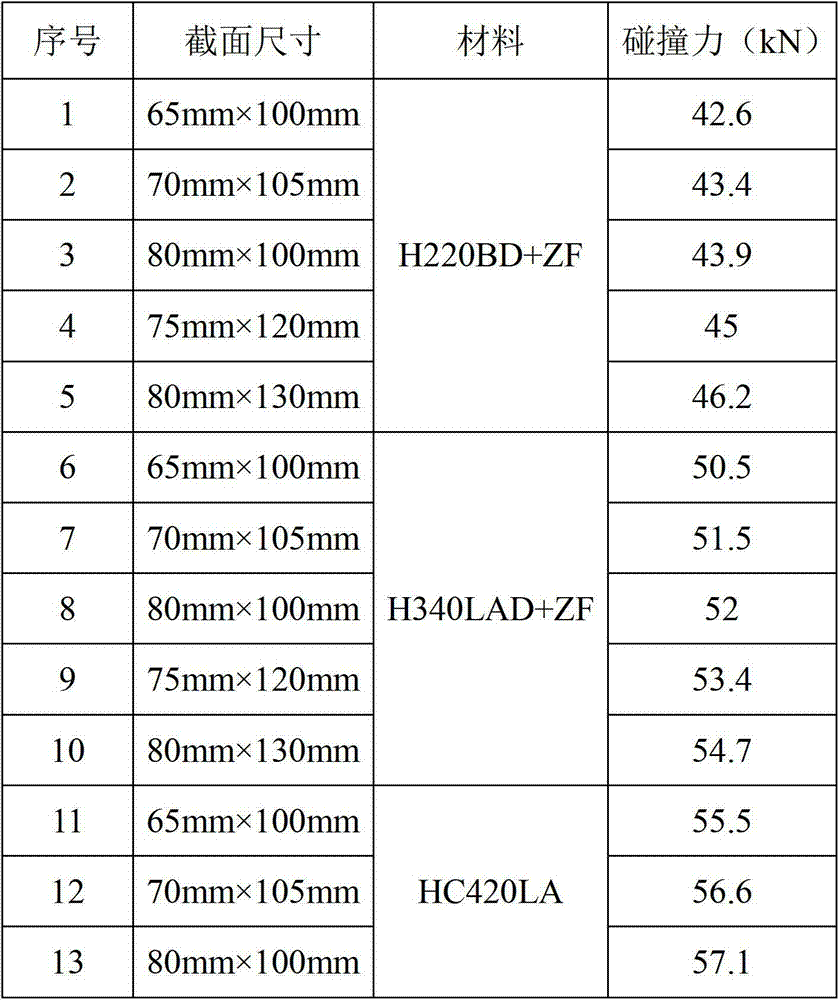

[0037] S3....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap