Hinge structure

A technology of hinge structure and cylinder, which is applied in gas shock absorber, pivot connection and other directions, can solve the problems of performance loss of hinge structure, damage of electronic device, and heavy weight of the two pivoted parts, so as to avoid performance loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

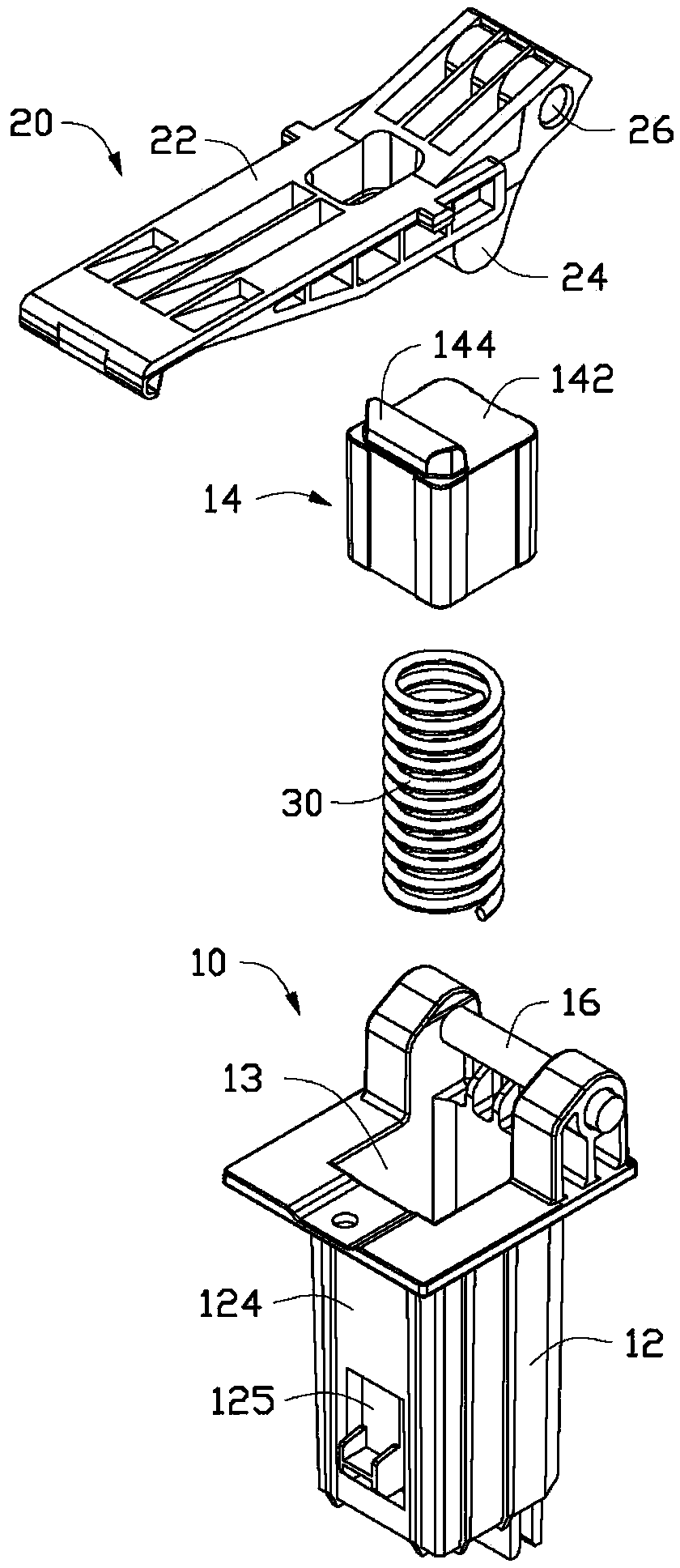

[0024] See Figure 1 to Figure 3 In a preferred embodiment of the present invention, a hinge structure includes a base 10, a rotating member 20, and an elastic member 30.

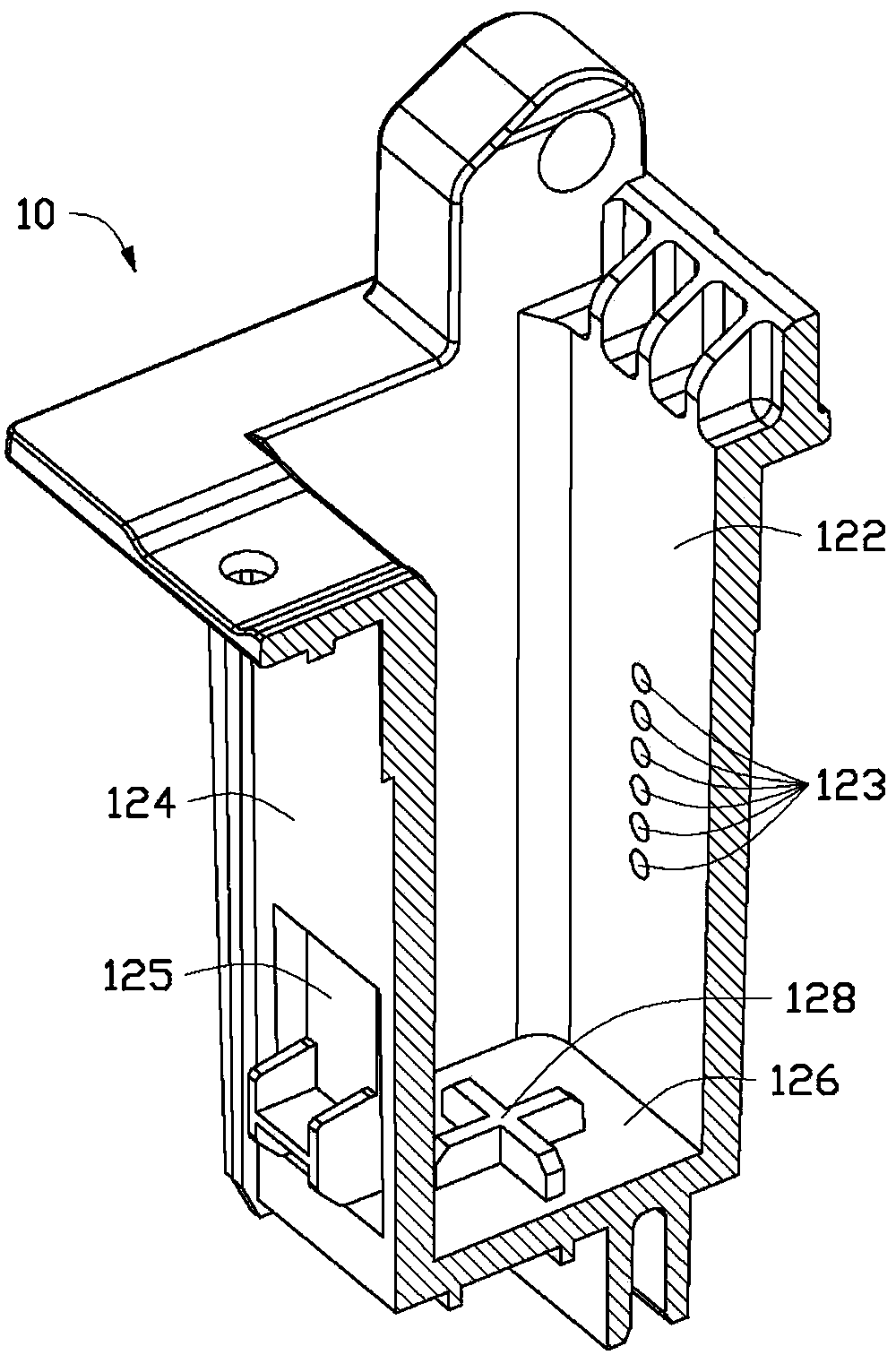

[0025] The base 10 includes a cylinder 12 and a piston 14 matched with the cylinder 12, and the base 10 also includes a pivot shaft 16.

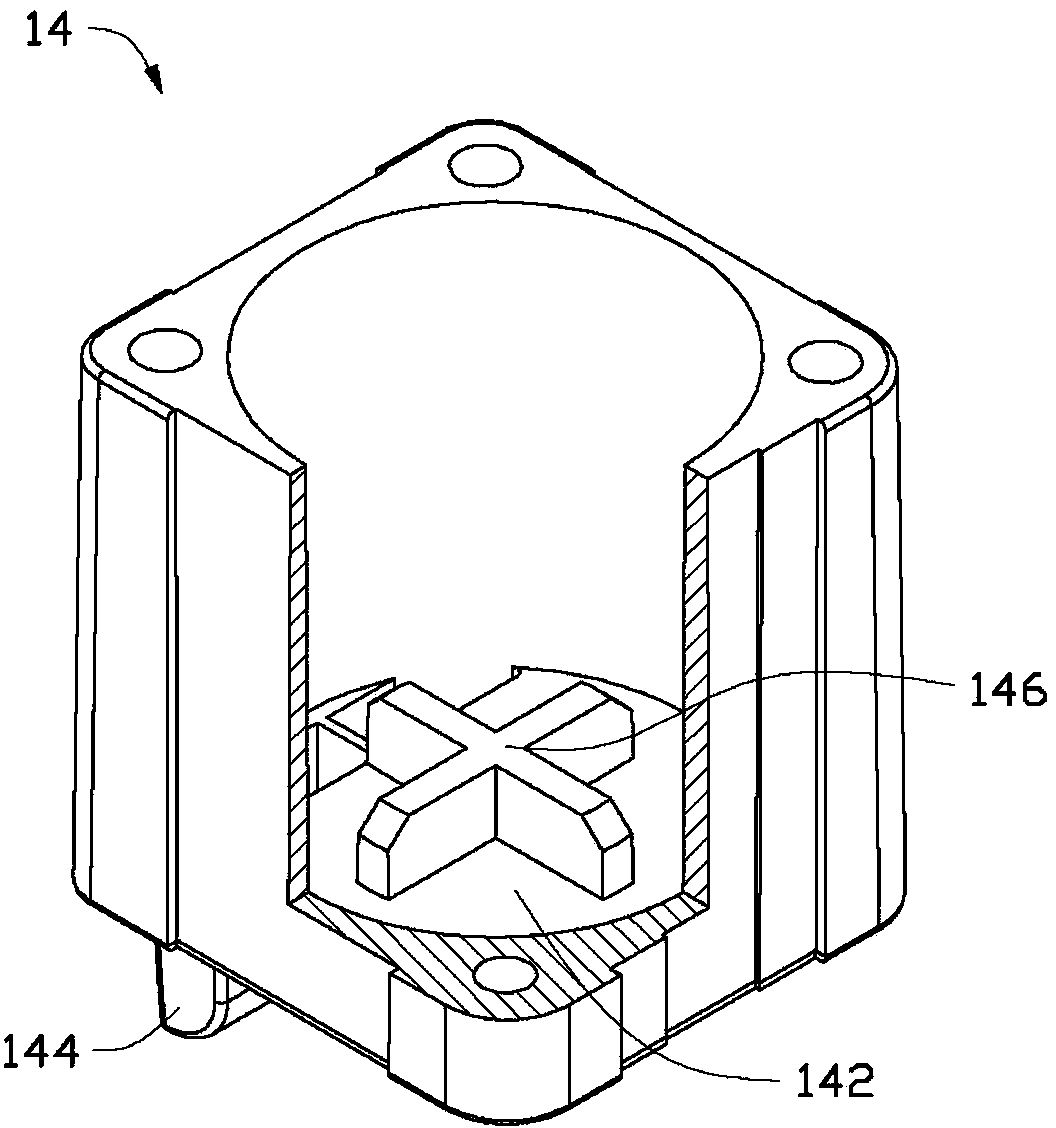

[0026] The cross-section of the cylinder 12 is approximately a rectangle, and the cross-section of the piston 14 matched with it is also approximately a rectangle. Such as Figure 5 with Image 6 As shown, an air chamber 13 is formed between the cylinder 12 and the piston 14. When the piston 14 moves along the axial direction of the cylinder 12 (the vertical direction shown in the figure), the piston 14 will A force (squeezing or stretching) is generated on the gas in the gas chamber 13. Those skilled in the art should understand that, in other embodiments, the cross-section of the cylinder 12 may also have other shapes, such as a circle, a hexagon, etc., and the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com