Feed granulator drive bearing

A technology for transmission bearings and granulators, applied in bearing components, roller bearings, shafts and bearings, etc., can solve the problems of high cost, low bearing capacity, easy damage, etc., to achieve strong bearing capacity, reduce repair rate, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

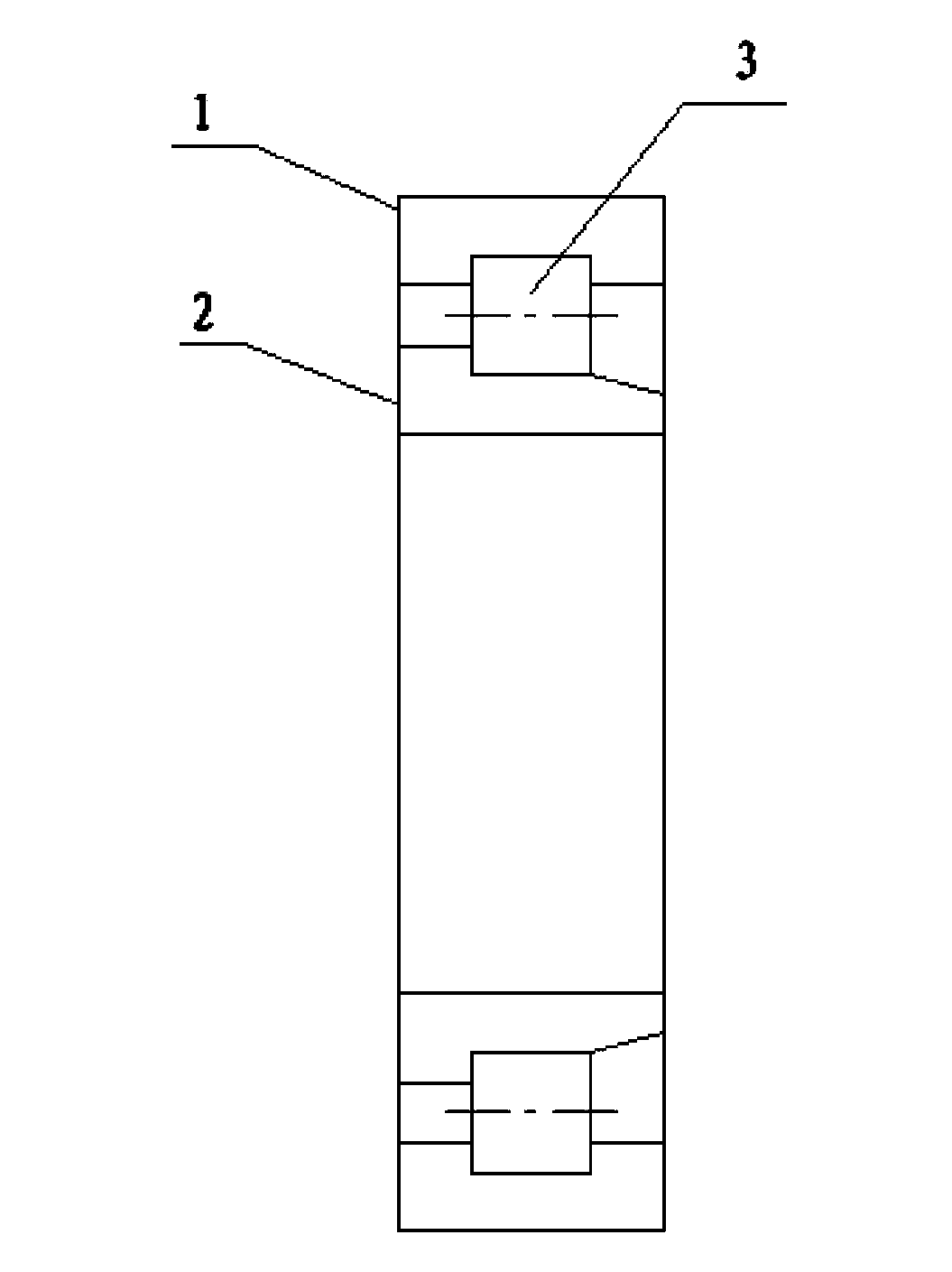

[0008] figure 1 Shown is a feed pellet machine transmission bearing, including a bearing outer ring 1, a bearing inner ring 2 and rolling elements. The rolling elements 3 are arranged between the bearing outer ring 1 and the bearing inner ring 2. An alloy wear-resistant layer is provided on the raceway of the contact portion between the body 3 and the bearing outer ring 1 and the bearing inner ring 2. The depth of the wear-resistant layer is 2-4 mm.

[0009] The above descriptions are only preferred embodiments of the present invention and are not intended to limit the present invention. Any modification, equivalent replacement, improvement, etc. made within the spirit and principle of the present invention shall be included in the protection of the present invention. Within range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap