Workbench for shaft processing and laser processing system based on workbench

A workbench and shaft technology, which is applied in the direction of furnace type, manufacturing tools, metal material coating process, etc., can solve the problem of easy bending deformation, limited effective processing length of laser cladding workbench, and inability to clamp slender shaft workpieces Avoid tightness and other problems, to achieve the effect of avoiding bending deformation, strong bearing capacity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them.

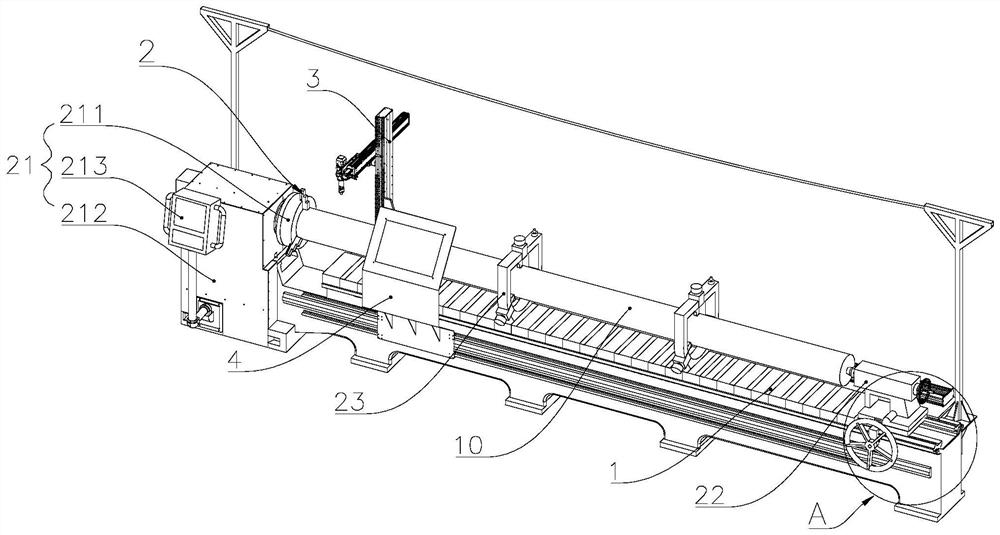

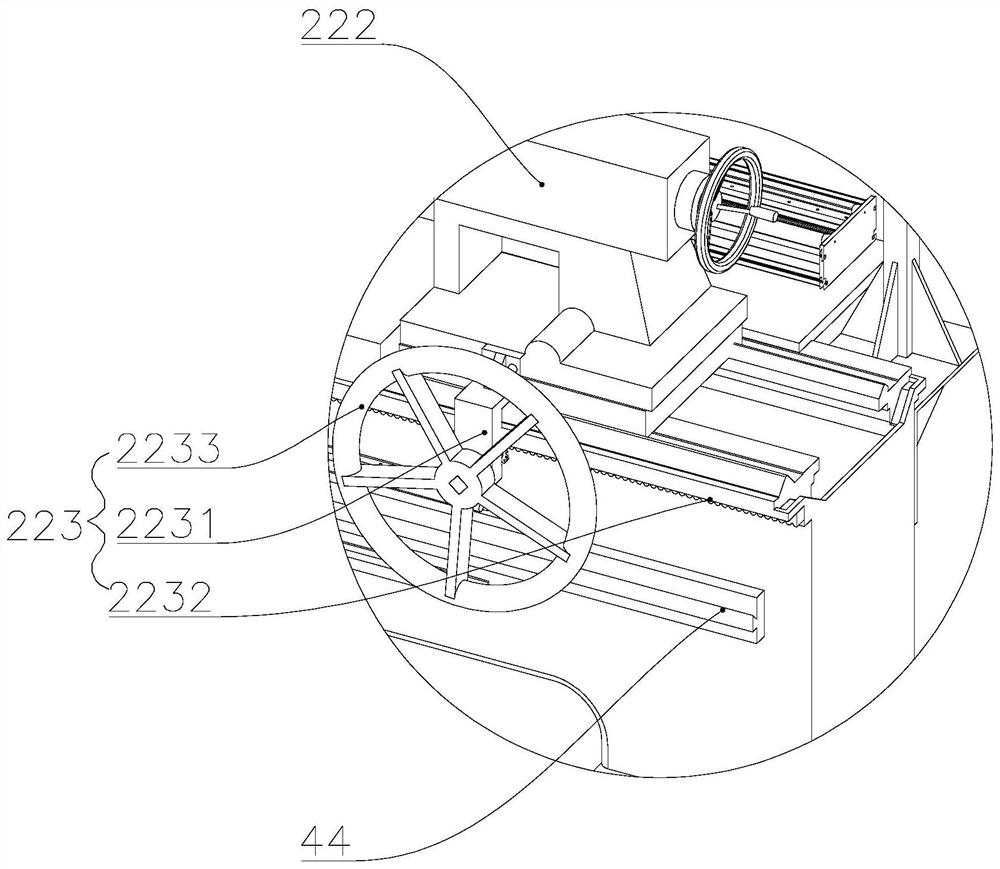

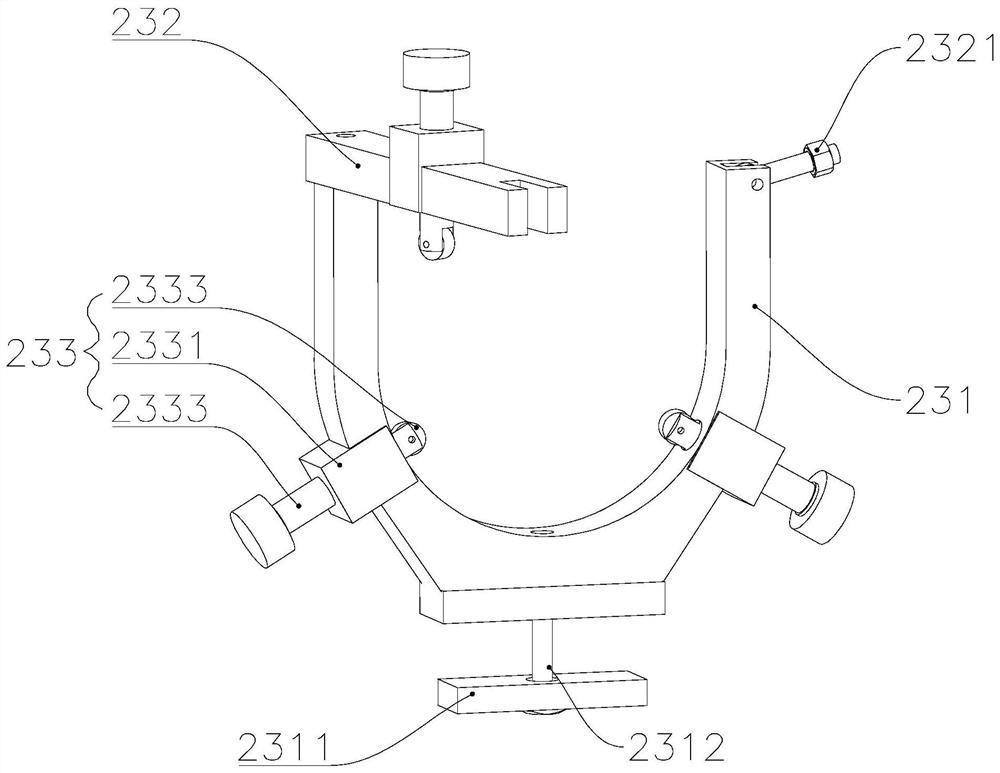

[0030] Such as figure 1 and 2 As shown, a workbench for shaft processing includes a horizontal bed 1, a clamping mechanism 2 and a laser module 3. The clamping mechanism 2 is arranged on the horizontal bed 1, and the clamping mechanism 2 is used for aligning shafts. The position of the part 10 is limited, and the laser module 3 is slidably arranged on one side of the horizontal bed 1 for processing the shaft part 10. The clamping mechanism 2 includes a three-jaw chuck 21, a moving tailstock 22 and several central support modules 23. The central support module 23 is arranged between the three-jaw chuck 21 and the movable tailstock 22, and the three-jaw chuck 21 and the movable tailstock 22 limit it from both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com