Coffin-shaped structure induction coil

An induction coil and coffin-shaped technology is applied in the field of intermediate frequency horizontal graphitization and sintering equipment, which can solve the problems of leakage of joints, high energy consumption, and inability to stack top insulating refractory bricks, and achieves the effect of repeated use and strong bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

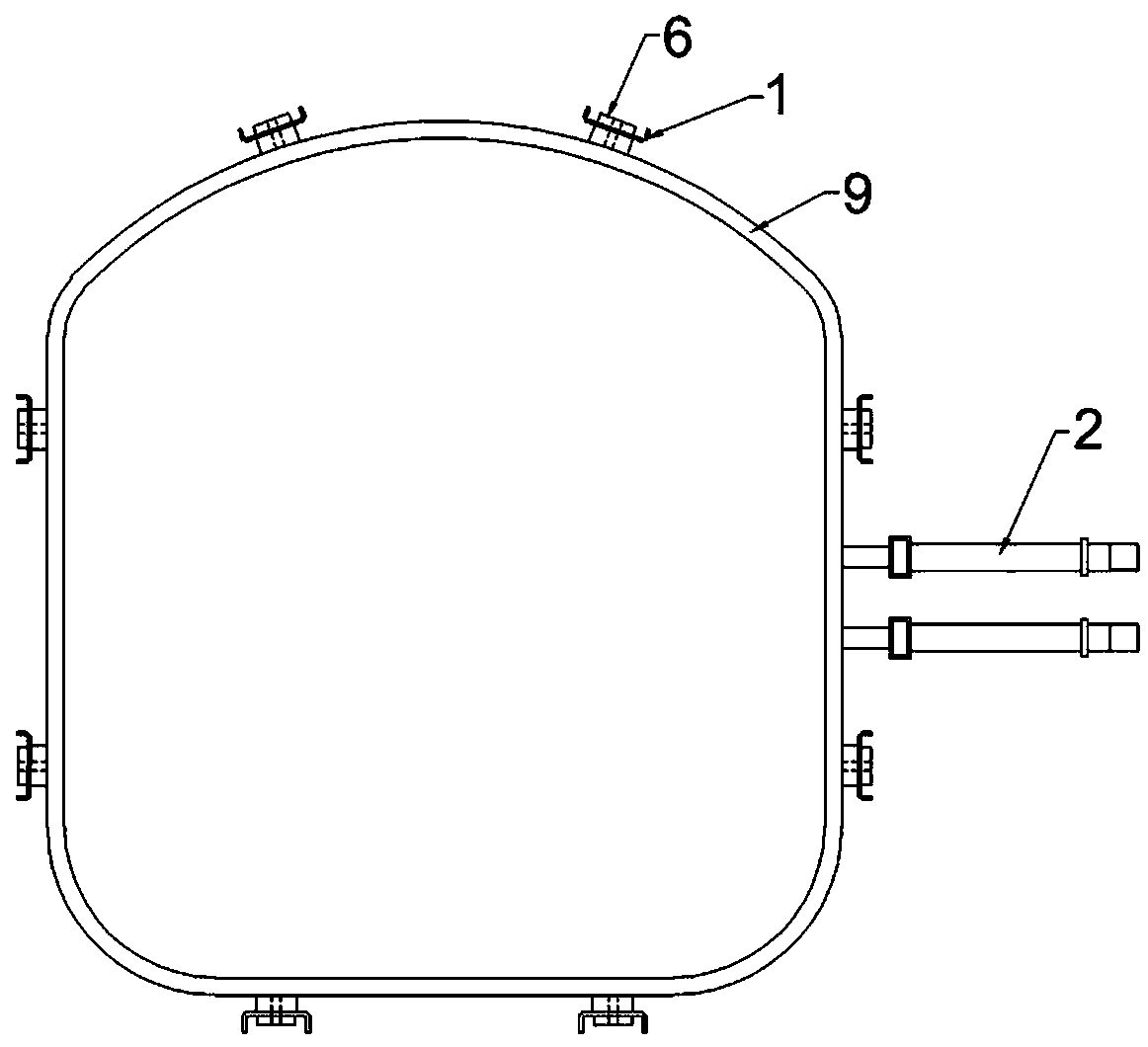

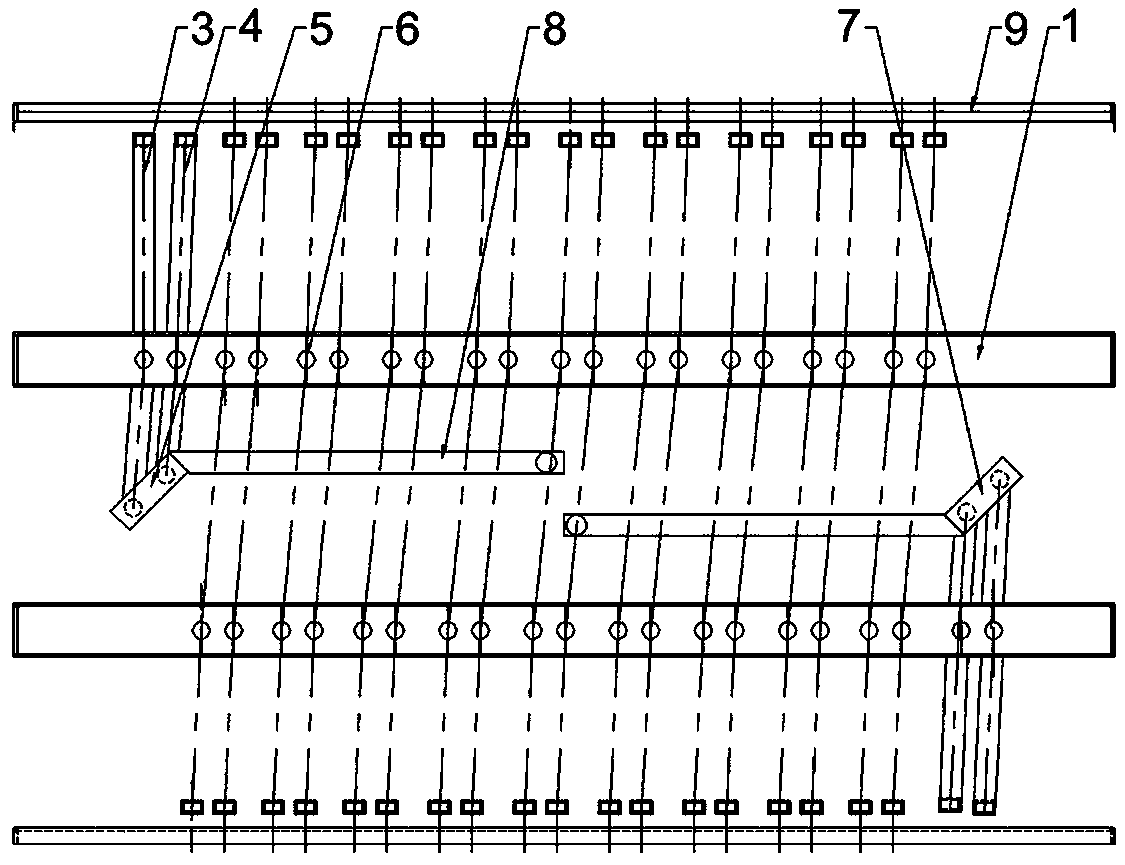

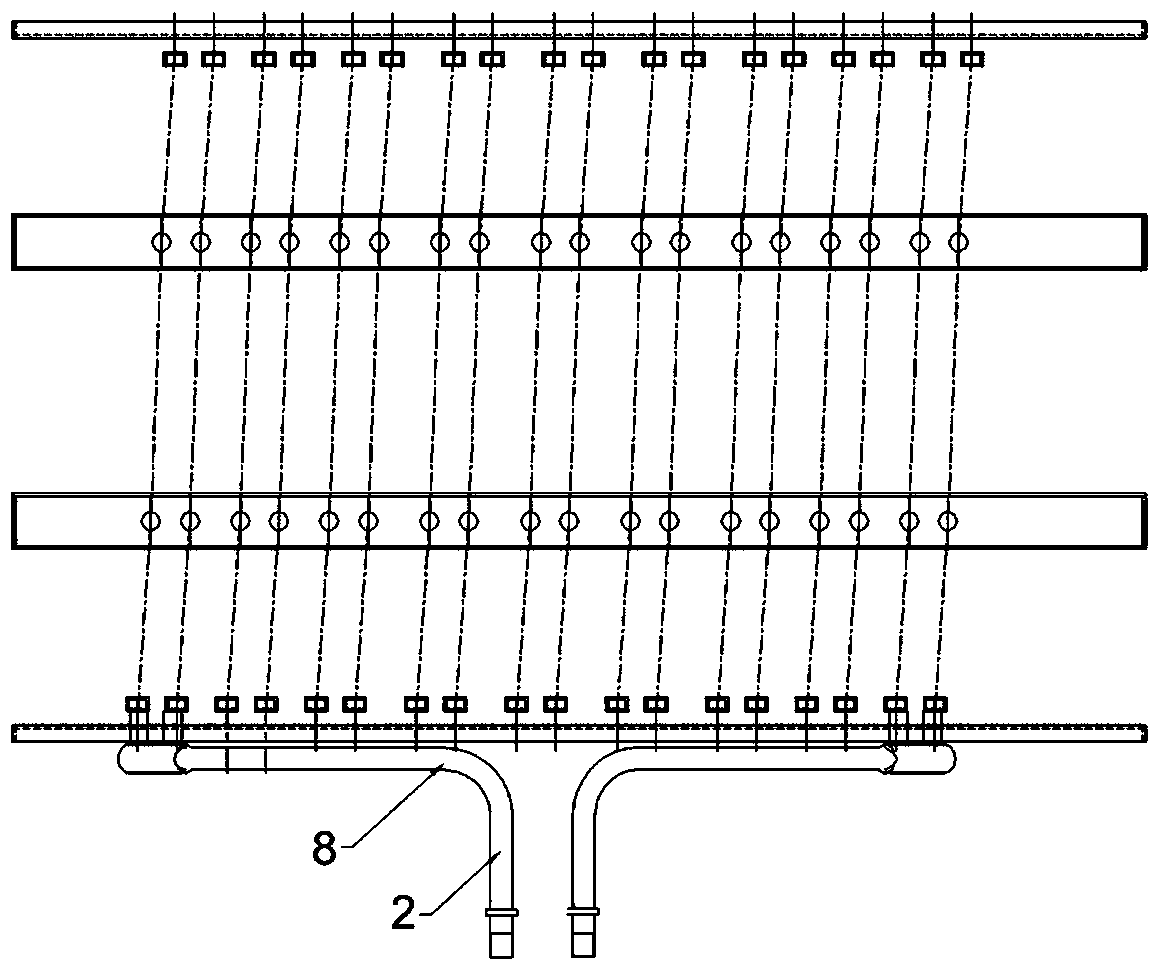

[0025] see Figure 1~Figure 3 A preferred embodiment of a coffin-shaped structure induction coil, in this embodiment, the main body of the induction coil includes a shaped frame 9, the cross section of the shaped frame 9 is a square plane on three sides, and a convex arc surface on the top Coffin-shaped structure, which is provided with a front end F-shaped connecting pipe 5 at the head position corresponding to the corresponding furnace body, and a rear-end F-shaped connecting pipe 7 is provided at the tail position of the corresponding furnace body, and the front F-shaped connecting pipe 5 is set The water level height is higher than the water level height set by the rear end F-shaped connecting pipe 7.

[0026] In this embodiment, two copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com