Discontinuously-perforated bridge frame

A bridge and bridge tube technology, applied in the field of bridges with intermittent holes, can solve the problems of easy deformation, high maintenance cost, low bridge rigidity, etc., and achieve the effects of strong bearing capacity, strong decorative function, and smooth and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

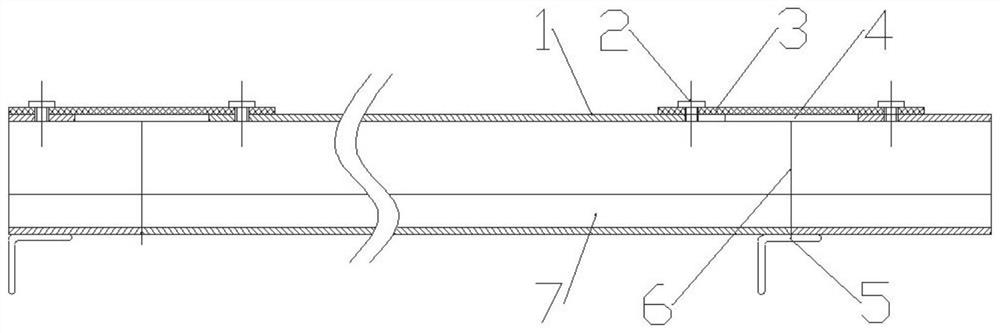

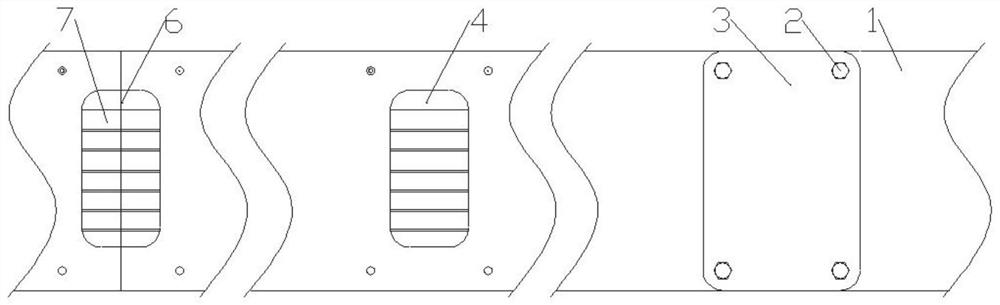

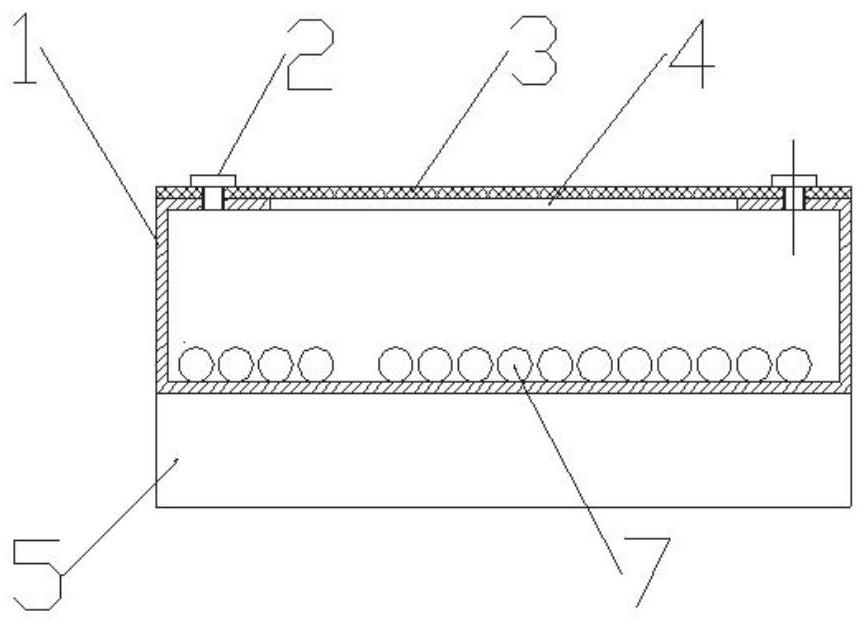

[0036] Such as Figure 1-3 As shown, a bridge frame with intermittent openings includes at least one set of bridge tubes 1, the surface of the bridge tubes 1 is open, and the surface of at least one set of openings has a cover plate assembly 3, and the cover plate assembly 3 is connected to the bridge frame through a connector 2. The pipe 1 is connected, and the cable 7 is located inside the bridge pipe 1.

[0037] The bridge tube 1 is a box-shaped structure, and can be made of metal materials such as steel plates, aluminum alloys, organic polymer materials such as polyvinyl chloride, or composite materials, and other materials. The polymer materials and their alloys are preferably selected to be produced by extrusion, and holes are opened on all circumferential surfaces of the bridge tube 1 after forming.

[0038] The opening can be used as a ventilation hole, and can also be used to pull and lay cables, bind and fix cables, check the condition of cables, and mark cable numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com